Toilet bent pipe production die and manufacturing process thereof

A manufacturing process and mold technology, which is applied in the field of toilet elbow production molds and its manufacturing process, can solve the problems of difficult demoulding of toilet elbows, damage to elbows or toilets, etc., so as to achieve not easily deformed, improve quality, and compressive capacity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

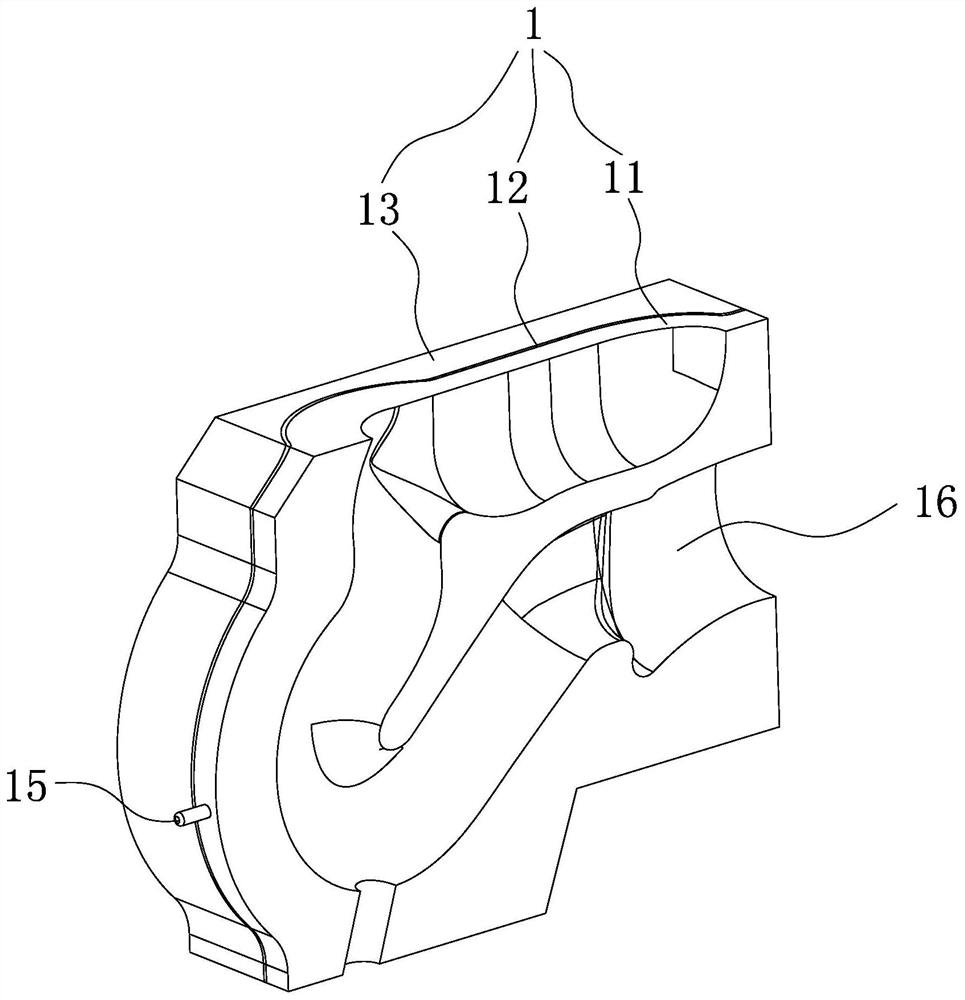

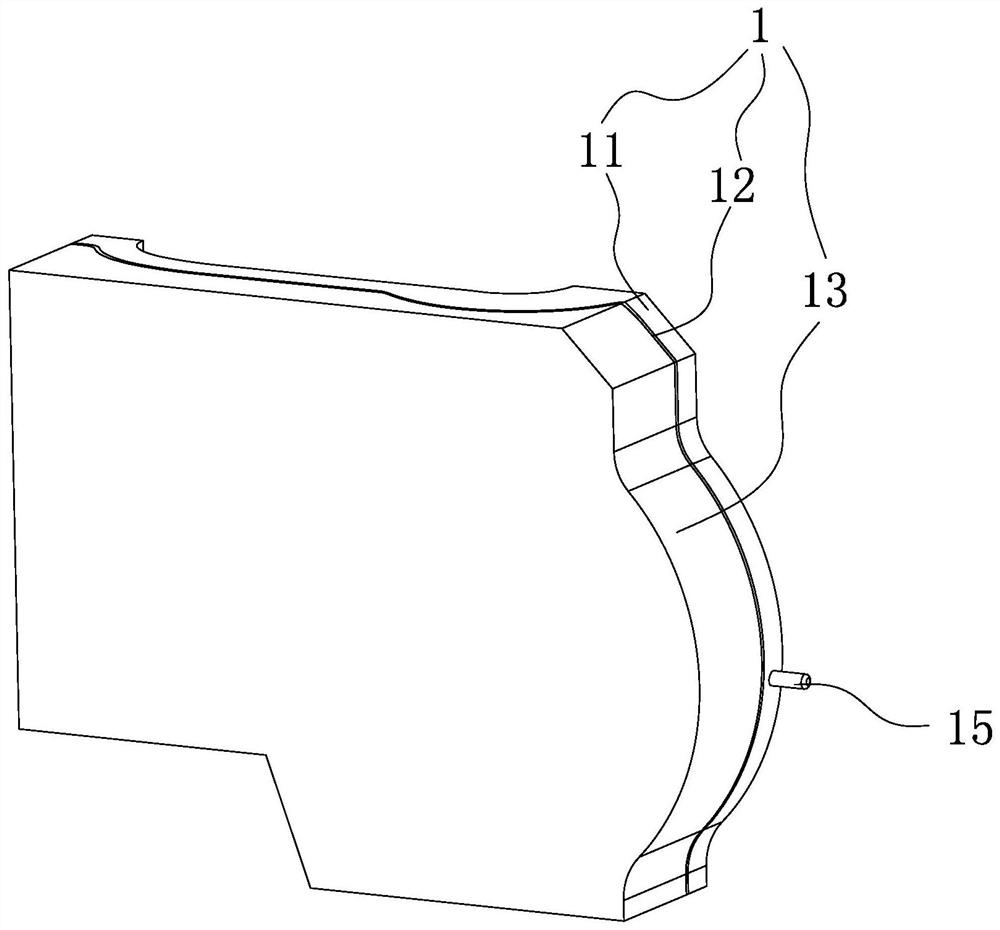

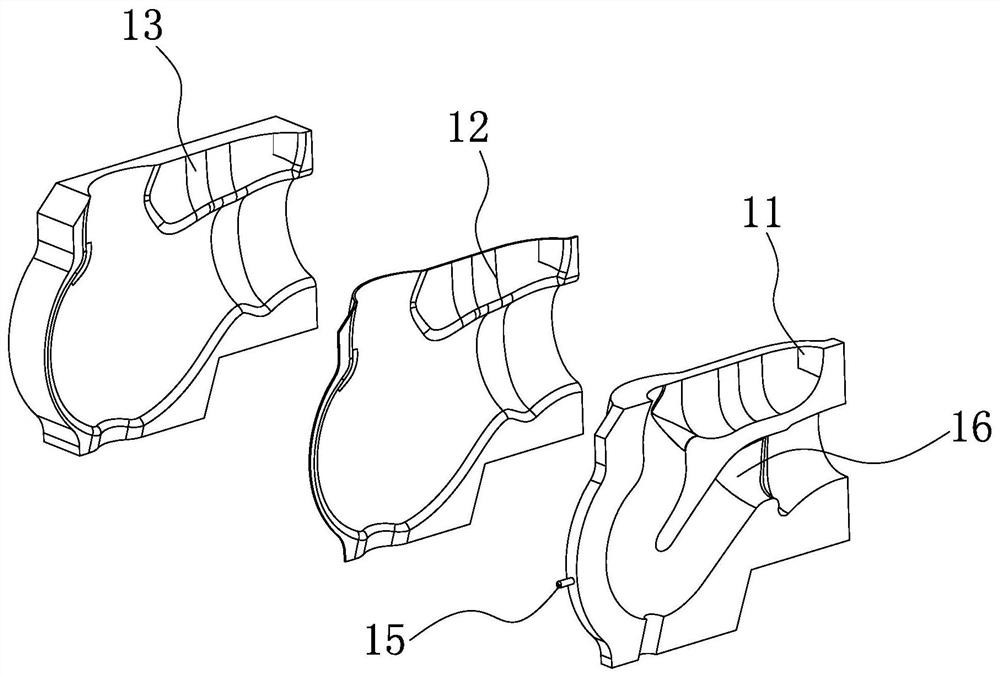

[0035] refer to Figure 1 to Figure 10, the present embodiment provides a toilet elbow production mold, including a left mold 1 and a right mold, the structure of the right mold and the left mold 1 is symmetrical, and the left mold 1 includes a drainage and exhaust inner layer 11 superimposed from the inside to the outside, waterproof The air-proof layer 12, the drainage and exhaust inner layer 11 are provided with a plurality of ventilating cavities 14, and the plurality of ventilating cavities 14 are densely distributed in the draining and exhausting inner layer 11, and the left mold 1 is provided with a vent hole 15, and the vent hole 15 Conducted to at least one air-permeable cavity 14 , the inner layer 11 of drainage and exhaust is provided with a left mold core 16 . An outer layer 13 is superimposed on the outer layer of the waterproof and air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com