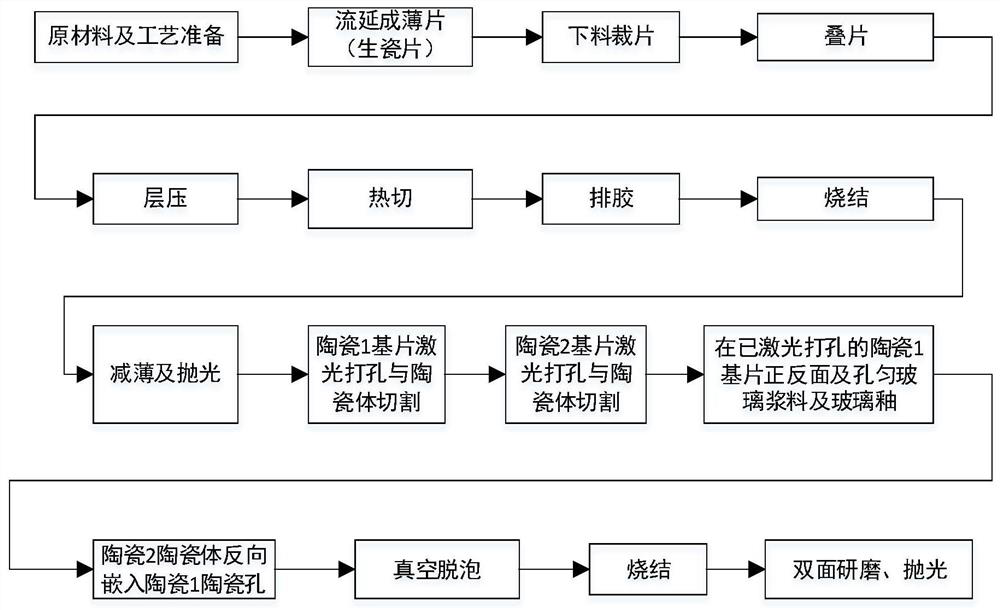

Preparation method of embedded heterogeneous ceramic substrate

A ceramic substrate and embedded technology, which is applied in the field of preparation of embedded heterogeneous ceramic substrates, can solve the problems of consistency, poor repeatability of batch production, large interconnection gap, large thickness tolerance of substrates, etc., to ensure reliable Excellent performance and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

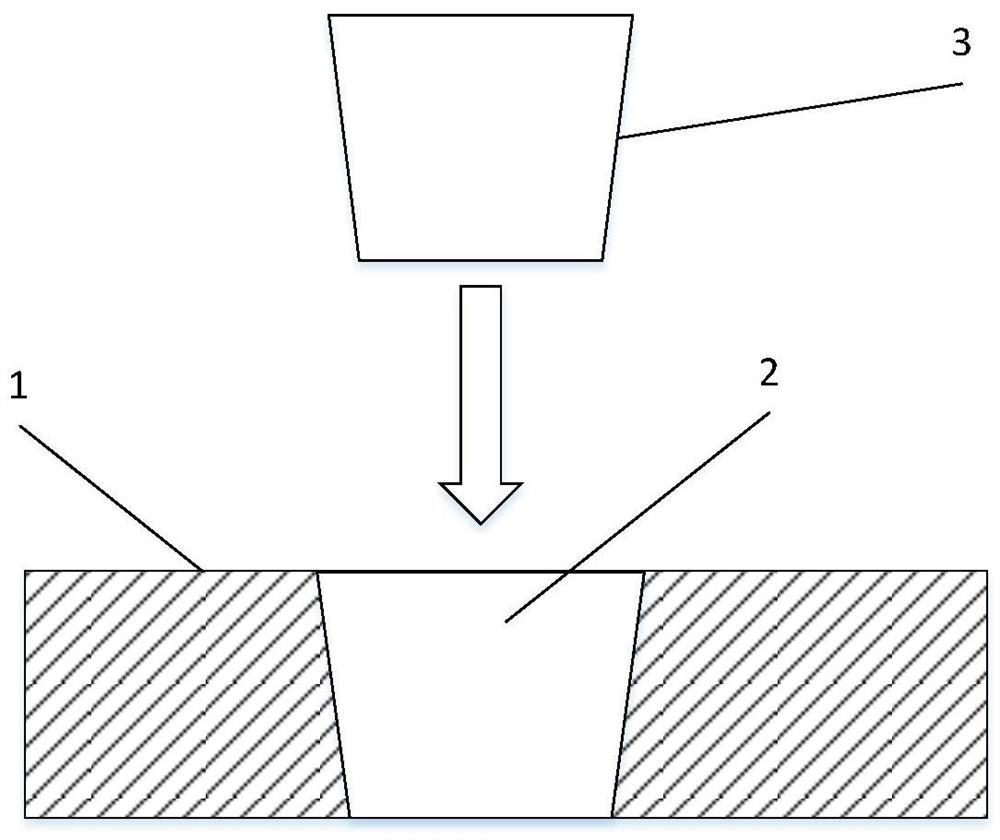

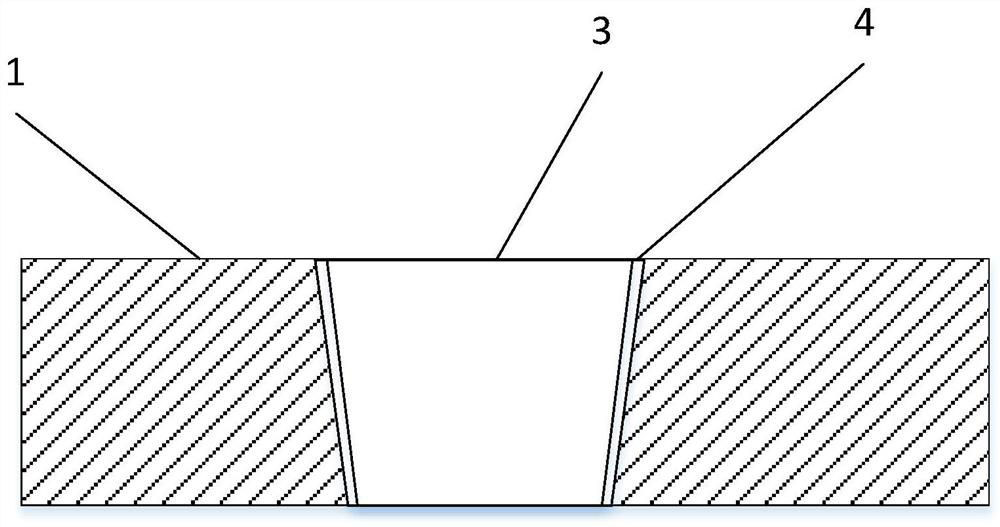

[0032] Embodiment 1: the embedded heterogeneous ceramic substrate that is made up of M25 microwave dielectric ceramic substrate and NZF microwave ferrite ceramic substrate, manufacturing steps are as follows:

[0033] (1) Ceramic substrate preparation

[0034] The formula of the M25 microwave dielectric ceramic material includes: 20%-30% MgO, 55%-70% TiO 2 , 2% ~ 10% CaCO 3 , 2% ~ 10% La 2 o 3 Etc (mass ratio), the dielectric constant is 25; according to the M25 microwave dielectric ceramic material formula, the raw materials are weighed separately, mixed by ball milling, and then the obtained mixture is put into a muffle furnace for pre-sintering to synthesize microwave dielectric ceramic powder body, pre-fired at 1100°C, and kept warm for 2 hours; the prepared M25 ceramic powder was prepared by adding organic solvents such as ethanol and toluene and binders such as PVB according to the conventional casting material preparation process to prepare the casting material; adop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com