Modification method for white carbon black

A white carbon black and modification technology, applied in the field of rubber reinforcing agent, can solve the problems of insufficient reaction of silane coupling agent, slow modification speed, low coverage rate, etc., so as to improve the modification effect of white carbon black, The effect of improving production efficiency and improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

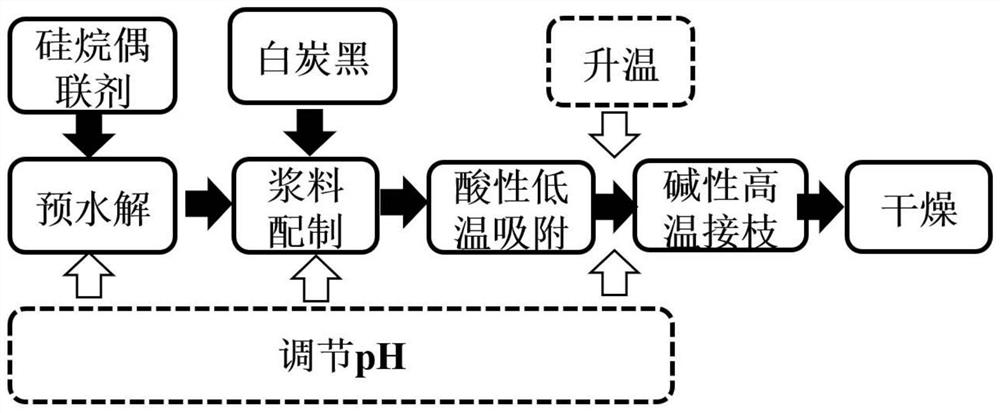

[0040] see figure 1 , the white carbon black modification method of the present invention, comprises the steps:

[0041] (1) Pre-hydrolysis of silane coupling agent

[0042] According to the molar ratio of water and γ-mercaptopropyltriethoxysilane (KH580) being 1:1, KH580 was configured as a 50% alcohol solution.

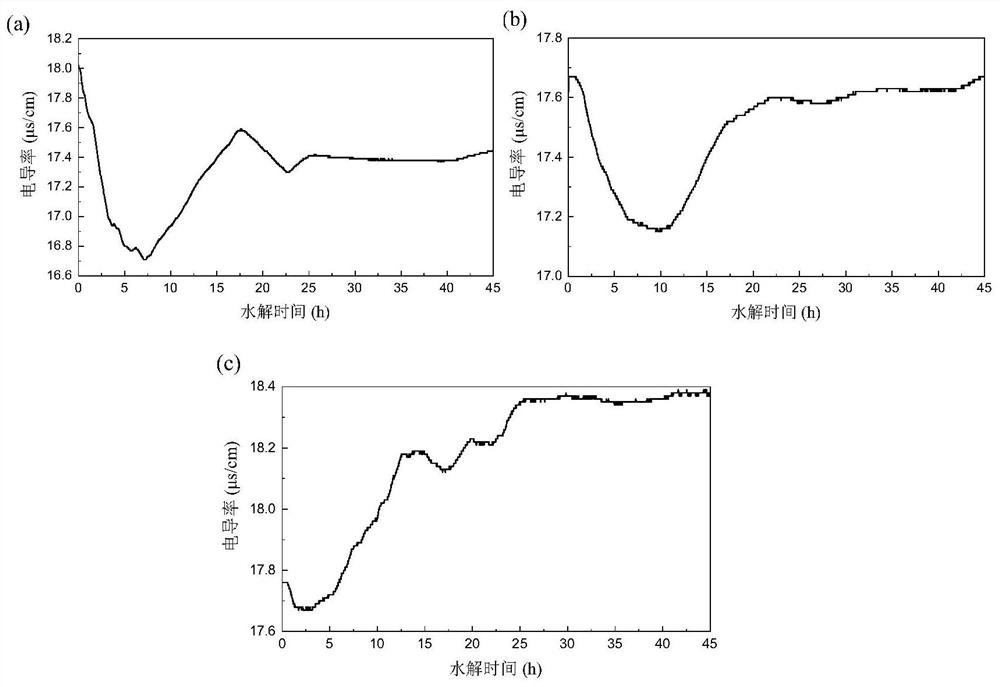

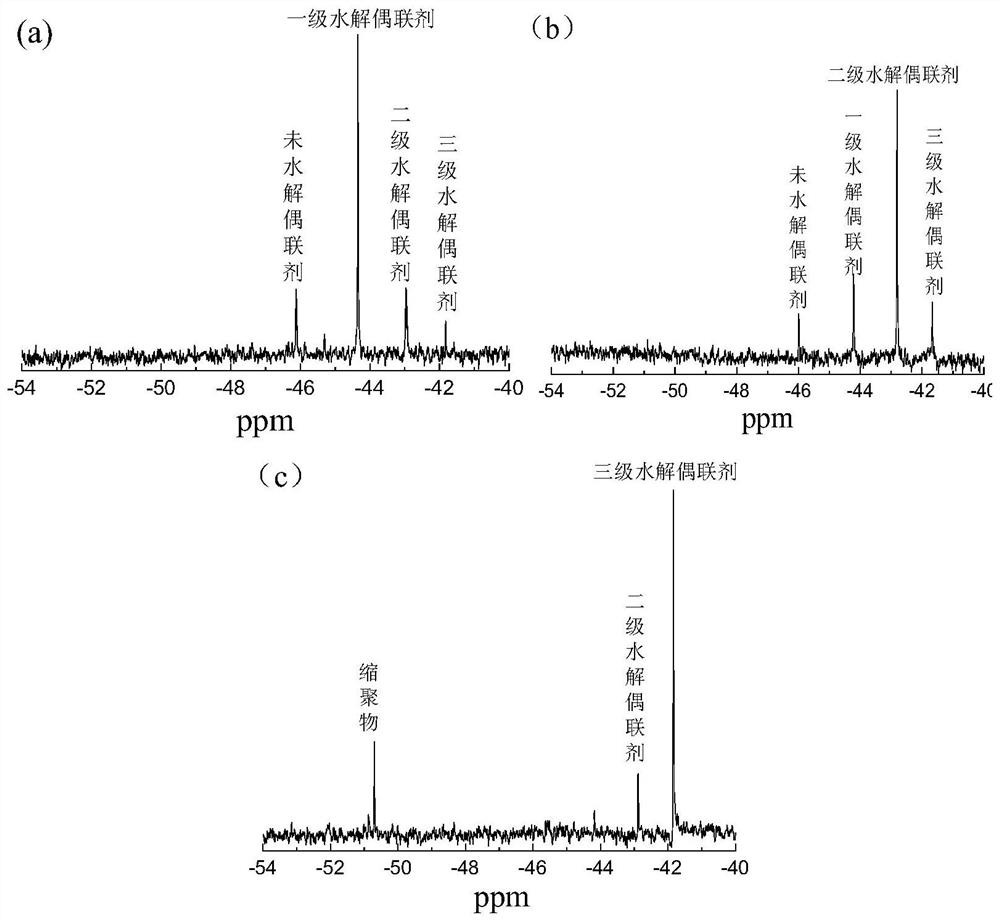

[0043] The specific steps are as follows: First, take appropriate amount of ethanol and water according to the ratio, stir for 20 minutes, and then use 4mol·L -1 The pH of the solution was adjusted to 3 with dilute sulfuric acid solution. Accurately weigh KH580 according to the proportion, slowly add it to the beaker, and stir while adding; after the configuration is completed, seal the beaker with a parafilm, and use a magnetic stirrer to continuously stir at 400rpm and 25°C for a period of time. The tester continuously tests the conductivity of the hydrolyzed solution, and determines the degree of hydrolysis of the hydrolyzed solution according to the result of...

Embodiment 2

[0054] see figure 1 , Example 2 of the present invention provides another silica modification method, which differs from the method in Example 1 in that the molar ratios of water and KH580 are 1:2, respectively.

[0055] Has the following steps:

[0056] (1) Pre-hydrolysis of silane coupling agent

[0057] According to the molar ratio of water and KH580 respectively 1:2, configure KH580 into 50% alcohol solution.

[0058] The specific steps are as follows: First, take appropriate amount of ethanol and water according to the ratio, stir for 20 minutes, and then use 4mol·L -1 The pH of the solution was adjusted to 3 with dilute sulfuric acid solution. Accurately weigh KH580 according to the proportion, slowly add it to the beaker, and stir while adding; after the configuration is completed, seal the beaker with a parafilm, and use a magnetic stirrer to continuously stir at 400rpm and 25°C for a period of time. The tester continuously tests the conductivity of the hydrolyzed ...

Embodiment 3

[0069] see figure 1 , Embodiment 3 of the present invention provides another method for modifying silica, which differs from the method in Embodiment 1 in that the molar ratios of water and KH580 are respectively 1:20.

[0070] Has the following steps:

[0071] (1) Pre-hydrolysis of silane coupling agent

[0072] According to the molar ratio of water and KH580 respectively 1:20, configure KH580 into 50% alcohol solution.

[0073] The specific steps are as follows: First, take appropriate amount of ethanol and water according to the ratio, stir for 20 minutes, and then use 4mol·L -1 The pH of the solution was adjusted to 3 with dilute sulfuric acid solution. Accurately weigh KH580 according to the proportion, slowly add it to the beaker, and stir while adding; after the configuration is completed, seal the beaker with a parafilm, and use a magnetic stirrer to continuously stir at 400rpm and 25°C for a period of time. The tester continuously tests the conductivity of the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com