Anti-leakage construction method for basement post-cast strip

A construction method and technology of post-pouring tape, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of unsatisfactory waterproof effect of waterproof layer, increase of construction cost, delay of construction period, etc., and achieve improved water leakage and waterproof Water permeability, enhanced waterproof ability, enhanced mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A basement post-pouring belt anti-seepage construction method, the specific steps are:

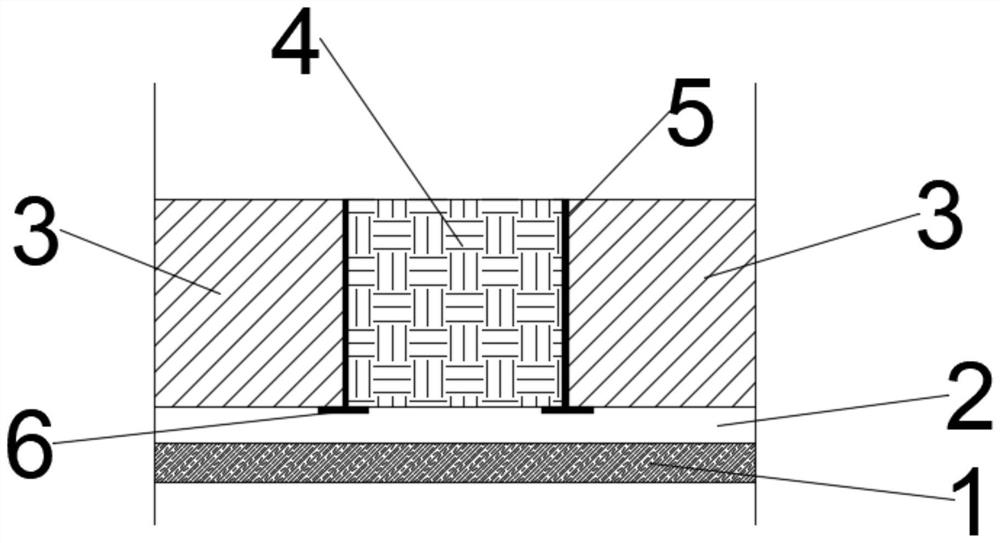

[0050] Step 1, clean up the construction area of the basement post-cast belt, and use concrete to pave the foundation cushion 1;

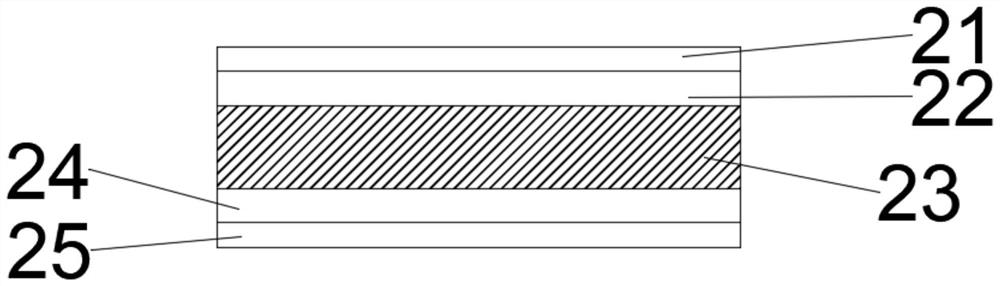

[0051] Step 2, after the construction and maintenance of the foundation cushion 1 is completed, a layer of waterproof membrane 2 is laid on it;

[0052] Step 3, using concrete to pour the foundation body 3 above the waterproof membrane 2, and maintaining the foundation body 3;

[0053] Step 4, after the maintenance of the foundation body 3 is completed, the joint between it and the post-casting tape 4 is chiseled, and the bonding material layer 5 is applied;

[0054] Step 5, using shrinkage-compensating concrete to pour out the post-cast belt 4 at the joint, and then maintain it again.

[0055] The waterstop 6 is pre-embedded at the connection between the waterproof coiled material 2 and the lower part of the seam, and then the post-casting tape 4 is...

Embodiment 2

[0085] A basement post-pouring belt anti-seepage construction method, the specific steps are:

[0086] Step 1, clean up the construction area of the basement post-cast belt, and use concrete to pave the foundation cushion 1;

[0087] Step 2, after the construction and maintenance of the foundation cushion 1 is completed, a layer of waterproof membrane 2 is laid on it;

[0088] Step 3, using concrete to pour the foundation body 3 above the waterproof membrane 2, and maintaining the foundation body 3;

[0089] Step 4, after the maintenance of the foundation body 3 is completed, the joint between it and the post-casting tape 4 is chiseled, and the bonding material layer 5 is applied;

[0090] Step 5, using shrinkage-compensating concrete to pour out the post-cast belt 4 at the joint, and then maintain it again.

[0091] The waterstop 6 is pre-embedded at the connection between the waterproof coiled material 2 and the lower part of the seam, and then the post-casting tape 4 is...

Embodiment 3

[0121] A basement post-pouring belt anti-seepage construction method, the specific steps are:

[0122] Step 1, clean up the construction area of the basement post-cast belt, and use concrete to pave the foundation cushion 1;

[0123] Step 2, after the construction and maintenance of the foundation cushion 1 is completed, a layer of waterproof membrane 2 is laid on it;

[0124] Step 3, using concrete to pour the foundation body 3 above the waterproof membrane 2, and maintaining the foundation body 3;

[0125] Step 4, after the maintenance of the foundation body 3 is completed, the joint between it and the post-casting tape 4 is chiseled, and the bonding material layer 5 is applied;

[0126] Step 5, using shrinkage-compensating concrete to pour out the post-cast belt 4 at the joint, and then maintain it again.

[0127] The waterstop 6 is pre-embedded at the connection between the waterproof coiled material 2 and the lower part of the seam, and then the post-casting tape 4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com