Novel PE pipe body with anti-bonding inner wall

A new type of anti-adhesion technology, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve the problems of non-cleaning, easy deterioration, adhesion, etc., to achieve the effect of protecting pipes, buffering water hammer effect, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

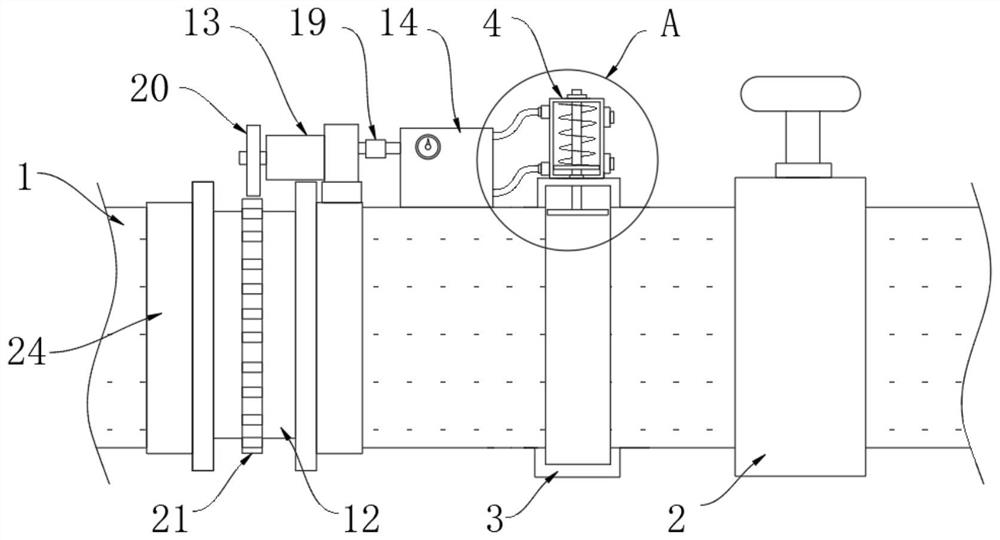

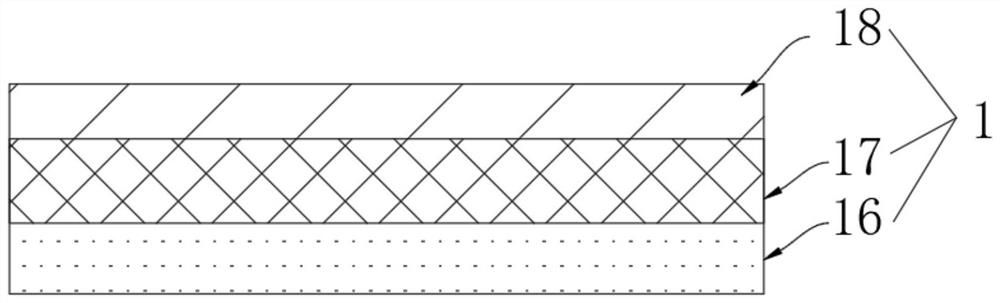

[0027] refer to Figure 1-4 , a new type of anti-bonding PE pipe body on the inner wall, including a pipe body 1, a control valve 2 is installed at one end of the pipe body 1, and a fixed pipe 3 is installed on the pipe body 1 near the control valve 2 and at the outlet end of the pipe body 1, The pipe body 1 is composed of a PE inner layer 16, a reinforcement layer 17 and a surface layer 18 from the inside to the outside. The material of the PE inner layer 16 is PE plastic, the material of the reinforcement layer 17 is stainless steel aluminum strip, and the material of the surface layer 18 is 2cm thick. Graphite coating.

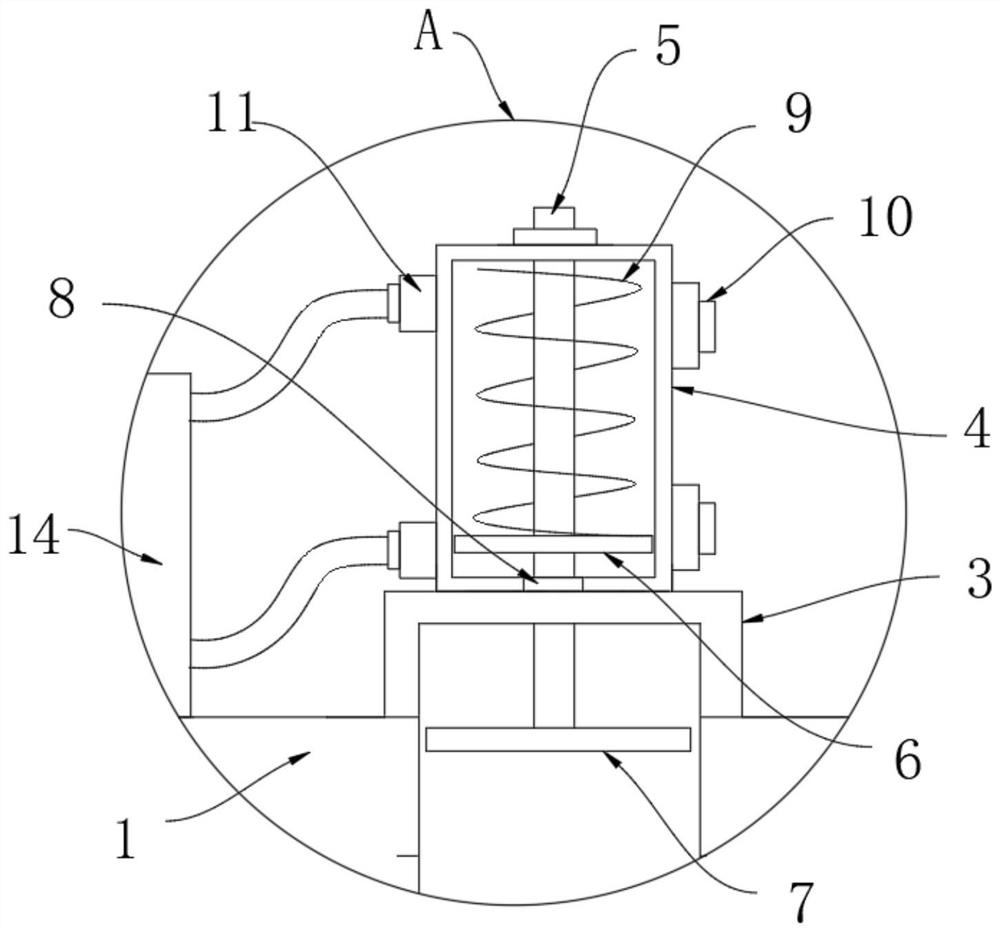

[0028] The surface of the fixed pipe 3 is provided with a pneumatic collection device, the pneumatic collection device is composed of a piston cylinder 4, a movable rod 5, a piston plate 6 and a push plate 7, the piston cylinder 4 is fixedly connected to the surface of the fixed pipe 3, and the upper and lower surfaces are provided with There is a through ...

Embodiment 2

[0033] refer to Figure 5-6 , different from Embodiment 1, the ring pipe 12 is installed in the middle of the pipe body 1, the material of the cleaning rod 15 is a stainless steel hollow pipe, and the side that fits the pipe body 1 is provided with multiple outlets, and the surface of the ring pipe 12 A liquid storage box 22 is installed, and the liquid storage box 22 communicates with the inside of the cleaning rod 15 through a connecting pipe 23 .

[0034] In this embodiment, the rotating ring pipe 12 can also be arranged in the middle of the pipe body 1, and the cleaning rod 15 can be arranged on both sides, so that the length of the cleaning rod 15 can be shortened. By setting the liquid storage box 22 and the connecting pipe 23, it can Add cleaning liquid to the inside of the cleaning rod 15, thereby improving the cleaning efficiency, which is convenient and quick.

[0035] During the use of the new anti-adhesion PE pipe body with inner wall proposed by the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com