Photoresist pattern trimming compositions and pattern formation methods

A technology of photoresist and composition, applied in the field of forming fine photoresist pattern, photoresist pattern trimming composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

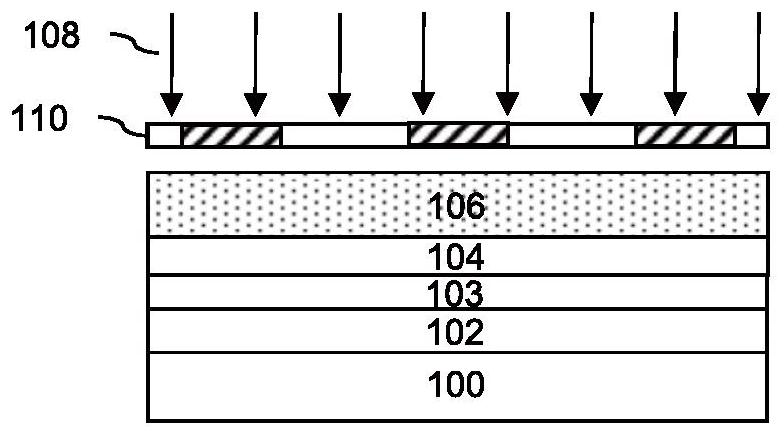

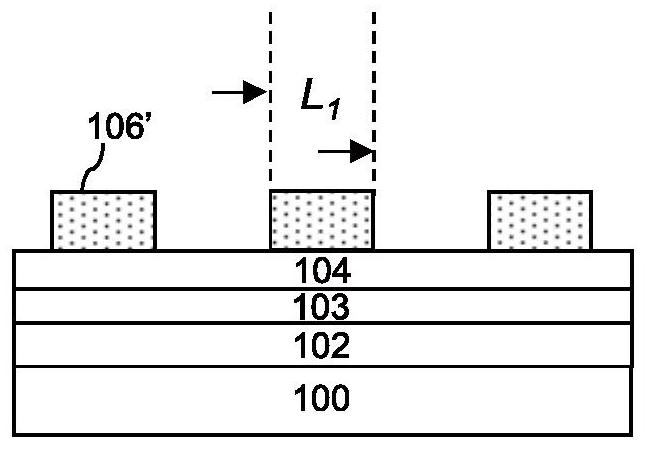

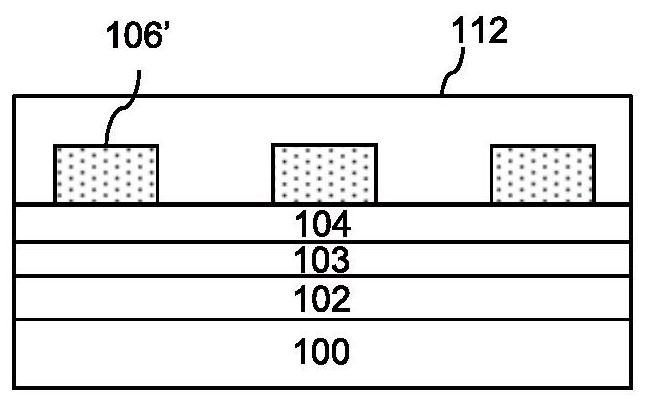

Method used

Image

Examples

example

[0064] polymer synthesis

[0065] Polymers were synthesized according to the procedure described below using the following monomers:

[0066]

Synthetic example 1

[0068]The monomer feed solution was prepared by mixing 8.78 g of methyl isobutyl methanol (MIBC) and 40.50 g of monomer M1 in the first vessel. The initiator feed solution was prepared by combining 1.91 g of Vazo-67 free radical initiator (E.I. duPont de Nemours and Company) and 17.20 g of MIBC in a second vessel and stirring the mixture to dissolve the initiator. 22.00 g of MIBC were introduced into the reaction vessel and the vessel was purged with nitrogen for 30 minutes. The reaction vessel was then heated to 90°C with stirring. Simultaneously, the introduction of the monomer feed solution and the initiator feed solution into the reaction vessel was initiated. The monomer feed solution was fed over a 2 hour period and the initiator feed solution was fed over a 3 hour period. The reaction vessel was maintained at 90°C with stirring for an additional 7 hours and then allowed to cool to room temperature. The reaction mixture was precipitated from heptane (20x) to give poly...

Synthetic example 2

[0070] The monomer feed solution was prepared by dissolving 10.46 g monomer M2, 5.16 g monomer M3 and 5.63 g monomer M5 in 190 g ethyl lactate in a reaction vessel and heating the solution to 165°C. The initiator feed solution was prepared by combining 3.40 g of V-601 free radical initiator (Wako Chemical Company) and 34.50 g of ethyl lactate in a vessel and stirring the mixture to dissolve the initiator. The initiator feed solution was fed into the reaction vessel over a period of 0.5 hours. The reaction vessel was maintained at 165°C with stirring for an additional 24 hours and then allowed to cool to room temperature. The reaction mixture was precipitated from methanol:water 75:25 (wt%) (20x) to give polymer P2 (17 g, 81% yield) as a white solid. Mw, Mn and PDI were determined as described in Example 1. The monomer ratios and molecular weight results in the polymers are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com