A power supply no-load voltage regulator

A no-load voltage and adjusting device technology, which is applied in the direction of adjusting electrical variables, control/regulating systems, instruments, etc., can solve the contradiction between power no-load voltage safety and arc starting performance, cannot take into account safety and work performance, and weakens welding Power supply arcing performance and other issues to achieve the effect of improving applicability, ensuring safety, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

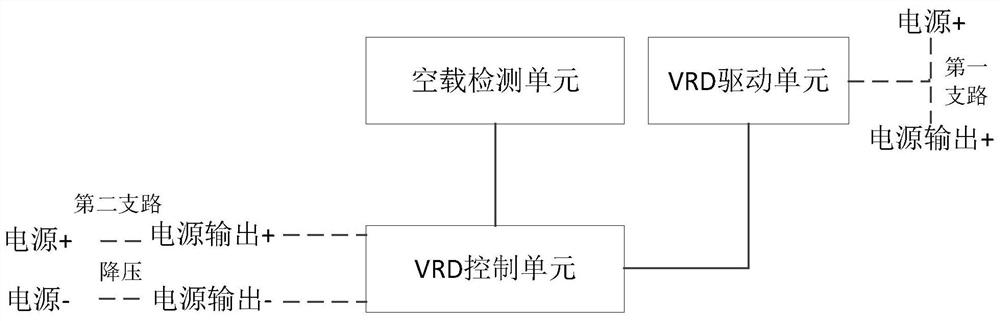

[0035] Such as figure 1 As shown, this embodiment provides a power supply no-load voltage regulator, including a no-load detection unit, a VRD drive unit, and a VRD control unit; the no-load detection unit is connected to the VRD drive unit via the VRD control unit, and the VRD control unit is connected to the VRD drive unit. The power supply output terminal is connected; the no-load detection unit is used to detect whether the electric energy device enters the no-load state, and sends a signal to the VRD control unit when the electric energy device enters the no-load state; the VRD control unit is used to receive the no-load detection When the signal is sent by the unit, control the VRD drive unit to cut off the connection between the positive pole of the power supply of the first branch and the positive pole of the power output terminal, so that the no-load voltage regulator of the power supply enters the no-load low-voltage safety mode; the VRD control unit is also used in t...

Embodiment 2

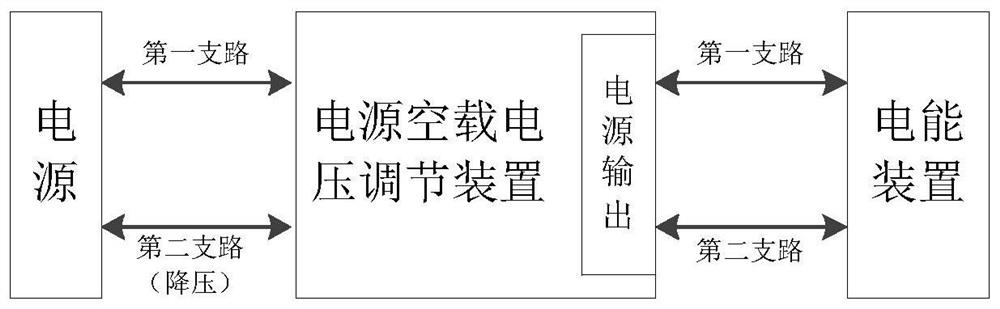

[0038] Such as figure 2 As shown, this embodiment provides a device for adjusting the no-load voltage of a power supply. Compared with Embodiment 1, the power supply no-load voltage adjustment device provided by this embodiment also includes a no-load voltage adjustment unit; the no-load voltage adjustment unit arranged between the power supply and the second branch of the power output terminal is used to adjust the second The voltage at the output terminal of the branch circuit.

[0039] The no-load voltage of the existing electric energy device is generally fixed. In this embodiment, the no-load voltage adjustment unit is used to adjust the step-down ratio between the power supply and the output terminal of the power supply, so as to realize the adjustment of the voltage at the output terminal of the power supply, so that the no-load voltage can be adjusted. , so as to be applicable to different usage scenarios and improve the applicability of the power supply no-load volt...

Embodiment 3

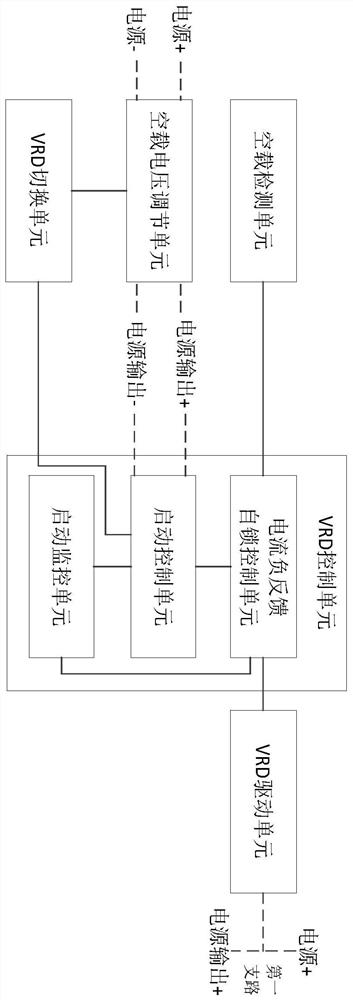

[0049] Such as image 3 As shown, this embodiment takes an arc welding machine as an example to provide a specific implementation of a no-load voltage regulator for a power supply.

[0050] In this embodiment, the no-load detection unit is used to detect whether there is current in the welding cable, so as to detect whether it is in a no-load state; the feedback self-locking control unit is specifically a current negative feedback self-locking control unit, and the start-up control unit is specifically a short-circuit trigger The arc control unit and the start monitoring unit are specifically the short-circuit anti-sticking control unit. The specific circuit connection relationship is as follows:

[0051] Wherein, the no-load detection unit includes a welding current sensor T2, the through hole of the welding current sensor T2 is provided with a welding cable, and the output end of the welding current sensor T2 is connected with the input end of the feedback self-locking cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com