Automatic feeding equipment for aquaculture industry

An aquaculture industry and automatic feeding technology, which is applied in the field of automatic feeding equipment in aquaculture industry, can solve the problems such as the inability to adjust the feeding angle, the inability to achieve full-angle feeding, the waste of manpower and aquatic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

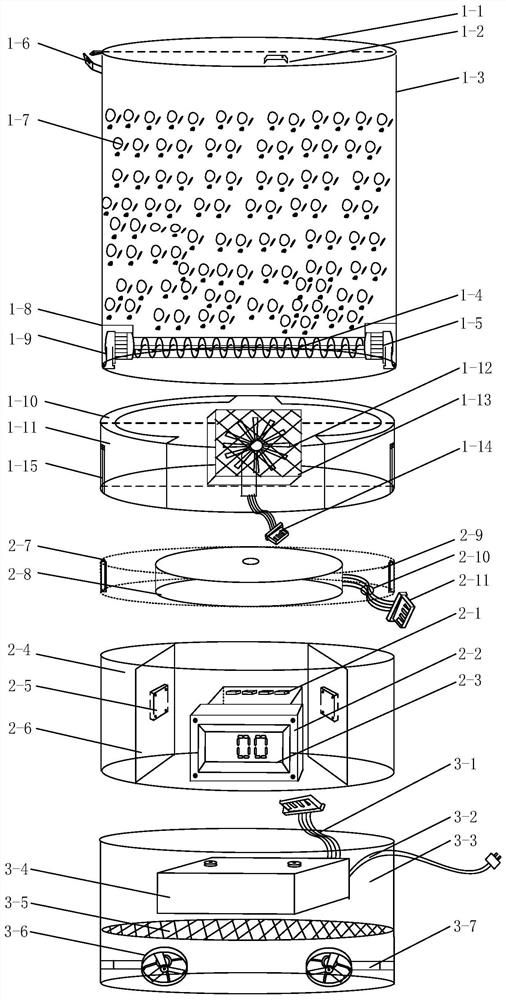

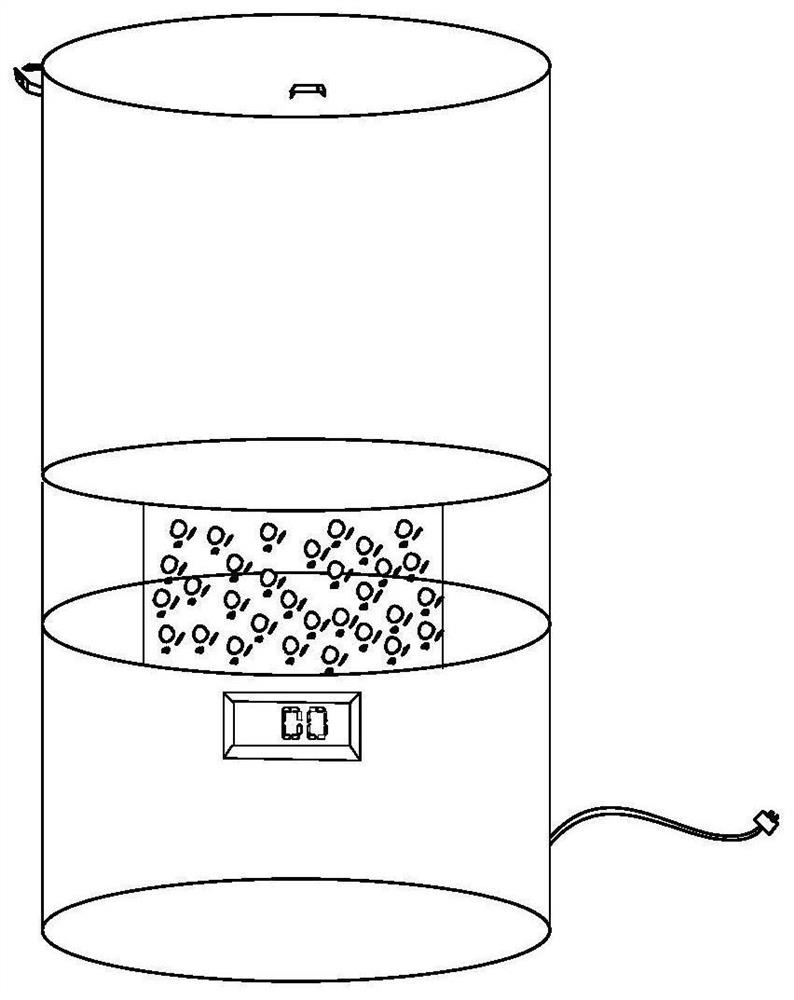

[0032] Embodiment 1: as Figure 1-11As shown, an automatic feeding device for aquaculture industry includes a working bin, a control bin, and a power bin arranged from top to bottom, wherein the working bin includes two parts: a storage bin and a feeding bin; the storage bin includes: Silo top shell 1-1, storage bin shell 1-3, screw feeding shaft 1-4, motor Ⅰ 1-5, storage bin body 1-7, isolation plate 1-8, motor Ⅱ 1-9; bait is placed in the storage Inside the silo body 1-7; the screw feeding shaft 1-4, the motor Ⅰ1-5 and the motor Ⅱ1-9 are all placed at the lower part of the storage silo body 1-7, and the isolation plate 1-8 is placed in the motor Ⅰ1-5 and the motor Ⅱ1 Above -9; the two ends of the screw feeding shaft 1-4 are respectively connected to the motor Ⅰ1-5 and the motor Ⅱ1-9; when the equipment is running, the motor Ⅰ1-5 and the motor Ⅱ1-9 control the screw feeding shaft 1-4 to rotate the feeding bait. The agglomeration and other phenomena caused by the storage envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com