A method for purifying elemental mercury in flue gas by using organic sulfide

A technology of sulfide and elemental mercury, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of decreased removal rate of elemental mercury, toxicity and corrosiveness, easy excess of hydrogen sulfide, etc. The effect of low ingredient requirements, simple ingredients and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

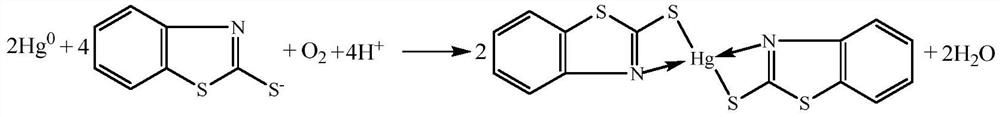

Method used

Image

Examples

Embodiment 1

[0028] Prepare a 2-mercaptobenzothiazole sodium washing solution with a concentration of 0.1mol / L. The simulated flue gas containing mercury (the gas composition is 250μg / m 3 Hg 0 , 2% SO 2 , 4%O 2 , and the rest are N 2 ) into 250 mL of washing liquid at a temperature of 25° C., the removal rate of elemental mercury is 97.5%.

Embodiment 2

[0034] Prepare a washing solution of trisodium thiocyanate with a concentration of 0.5 mol / L. The simulated flue gas containing mercury (the gas composition is 1000μg / m 3 Hg 0 , 10% SO 2 , 15%O 2 , and the rest are N 2 ) into 500 mL of washing liquid at a temperature of 60° C., the removal rate of elemental mercury is 98.4%.

Embodiment 3

[0040] Prepare a mixed washing solution of sodium 2-mercaptobenzothiazole and trisodium thiocyanate with a concentration of 0.15 mol / L. The simulated mercury-containing flue gas (gas composition is 600μg / m 3 Hg 0 , 0.1% SO 2 , 1%O 2 , and the rest are N 2 ) into 300 mL of washing liquid at a temperature of 10° C., the removal rate of elemental mercury is 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com