An amidoxime-based porous framework material, its preparation method and its application in adsorption and separation of uranium ions

A skeleton material and porous skeleton technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as unsatisfactory adsorption effect of uranium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing an amidoxime-based porous framework material, comprising the following steps:

[0026] (1) Carrying out Sholl reaction of aromatic cyano compound and aromatic compound under the action of catalyst to obtain cyano porous skeleton material; the catalyst is activated aluminum chloride;

[0027] (2) Carrying out amidoximation reaction of the cyano-based porous framework material obtained in the step (1), hydroxylamine hydrochloride and triethylamine to obtain the amidoxime-based porous framework material.

[0028] In the invention, the aromatic cyano compound and the aromatic compound are subjected to Shorer reaction under the action of a catalyst to obtain a cyano porous framework material.

[0029] In the present invention, the aromatic cyano compound preferably includes one or more of benzonitrile, 4-cyanobiphenyl, terephthalonitrile and 4,4'-biphenyldinitrile; the aromatic Compounds preferably include benzene, biphenyl, o-t...

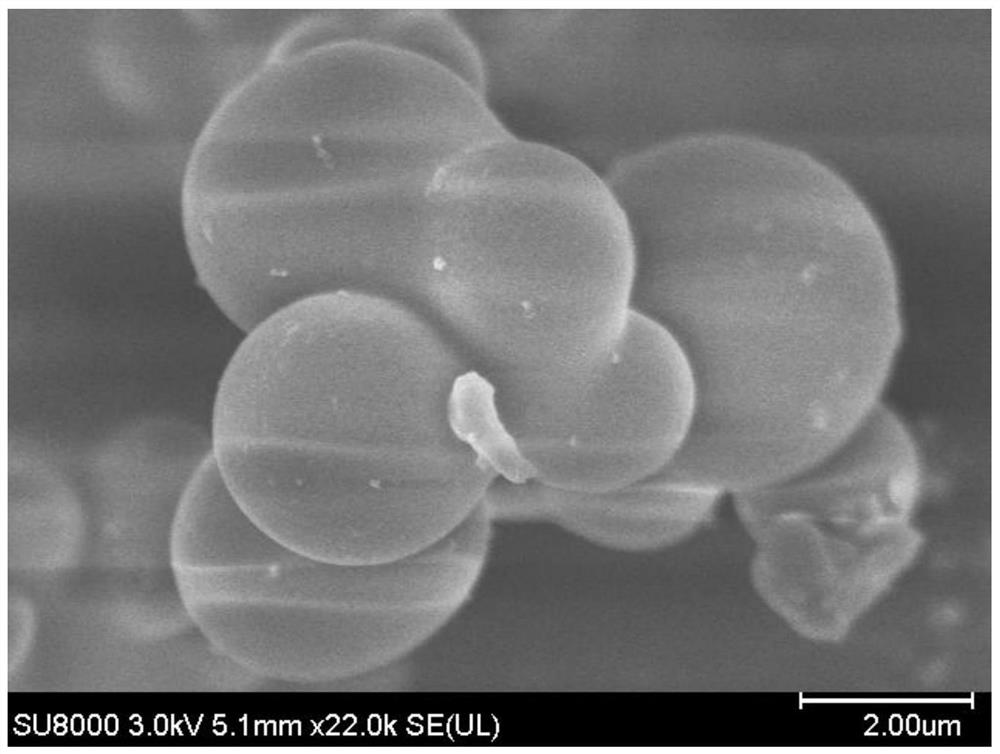

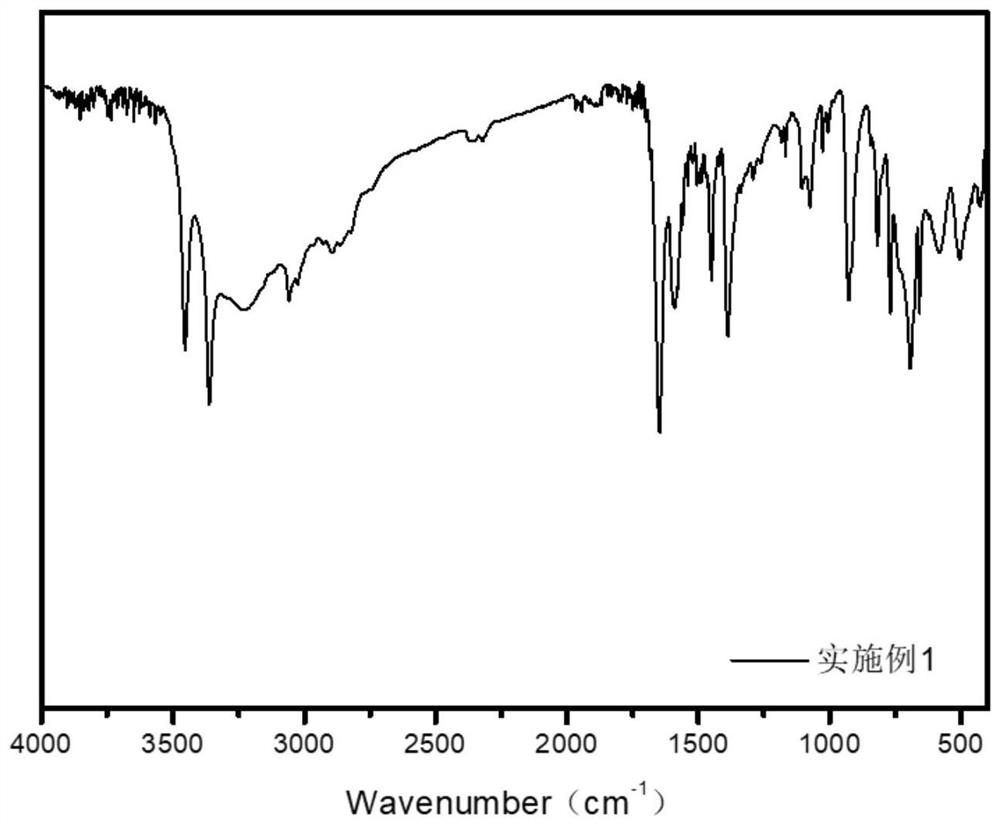

Embodiment 1

[0041] Add 500 mg of aluminum trichloride to the round bottom flask, vacuumize the flask, fill with nitrogen, then inject chloroform, and heat to 60° C. for 3 hours. Then add the chloroform solution of benzonitrile and biphenyl (ratio: 1:4) into the round-bottomed flask, and keep it at 60°C for 21 hours. After the reaction is completed and cooled, it is filtered, and the crude product obtained by filtration is washed with 1mol / L HCl solution treatment, followed by Soxhlet extraction with methanol, tetrahydrofuran and chloroform, respectively. Next, the obtained product was heated to 80° C. for 24 hours in a vacuum environment to obtain a cyano-based porous framework material. 200 mg of the cyano porous framework material was taken out and uniformly dispersed in ethanol, 0.5 g of hydroxylamine hydrochloride and 0.75 g of triethylamine were added, and then heated to 70° C. for 48 hours. After the reaction is cooled and filtered, the obtained product is first treated with 1mol / L...

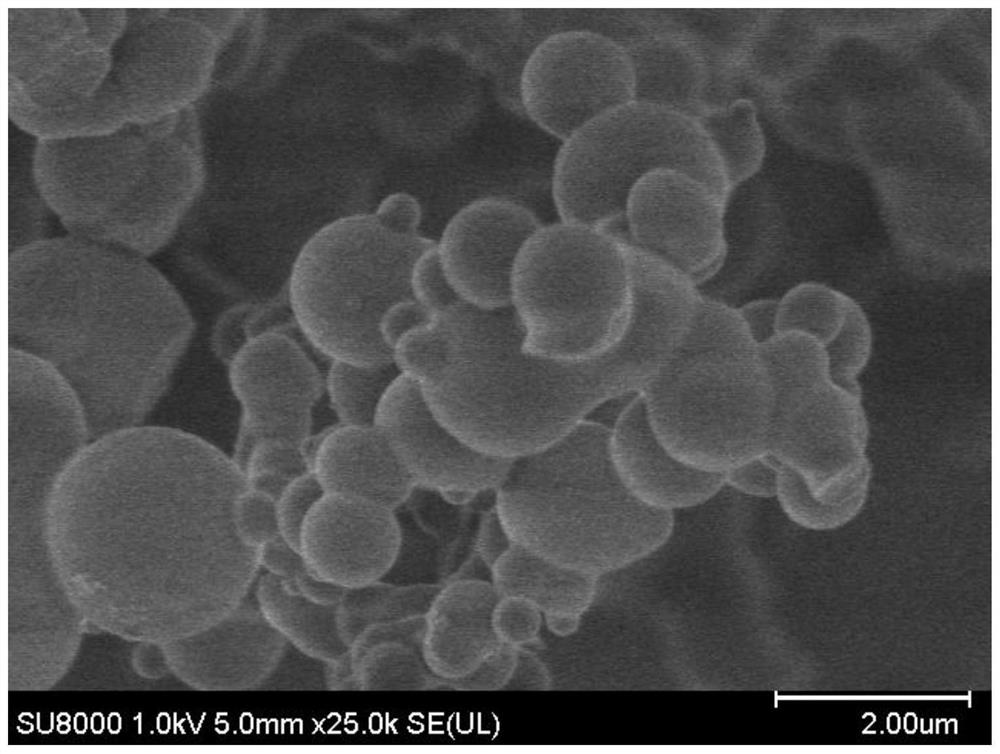

Embodiment 2

[0044] Add 500 mg of aluminum trichloride to the round bottom flask, vacuumize the flask, fill with nitrogen, then inject chloroform, and heat to 60° C. for 3 hours. Then add the chloroform solution of benzonitrile and biphenyl (ratio: 1:2) into the round-bottomed flask, and keep it at 60°C for 21 hours. After the reaction is completed and cooled, filter, and the crude product obtained by filtration is washed with 1mol / L HCl solution treatment, followed by Soxhlet extraction with methanol, tetrahydrofuran and chloroform, respectively. Next, the obtained product was heated to 80° C. for 24 hours in a vacuum environment to obtain a cyano-based porous framework material. 200 mg of the cyano porous framework material was taken out and uniformly dispersed in ethanol, 0.5 g of hydroxylamine hydrochloride and 0.75 g of triethylamine were added, and then heated to 70° C. for 48 hours. After the reaction is cooled and filtered, the obtained product is first treated with 1mol / L NaOH so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com