Preparation method and application of 2D-g-C3N4/1D-MWNTs/2D-rGO hybrid photocatalytic material

A 2d-g-c3n4, 1.2d-g-c3n4 technology, applied in the field of new energy conversion materials, to achieve the effect of improving visible light response ability, improving directional transmission ability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) MWNTs pretreatment: Add 1 g of MWNTs to 100 mL of concentrated nitric acid, heat and stir at 80 °C for 12 h, then centrifuge, wash and dry to obtain MWNTs with rich surface defects.

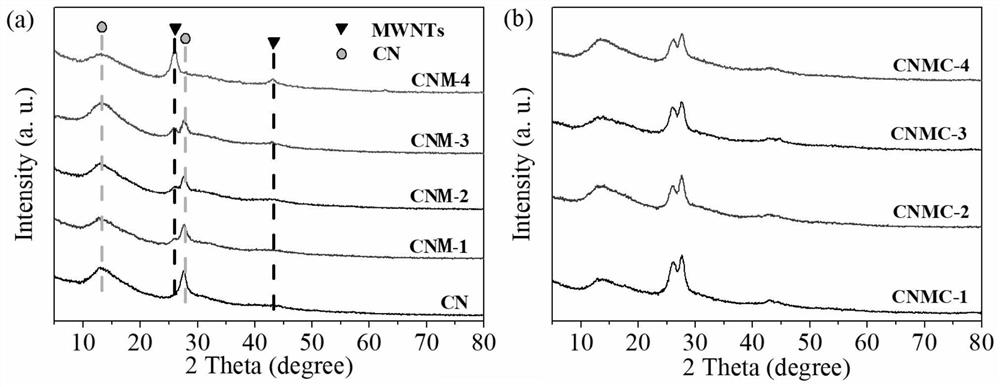

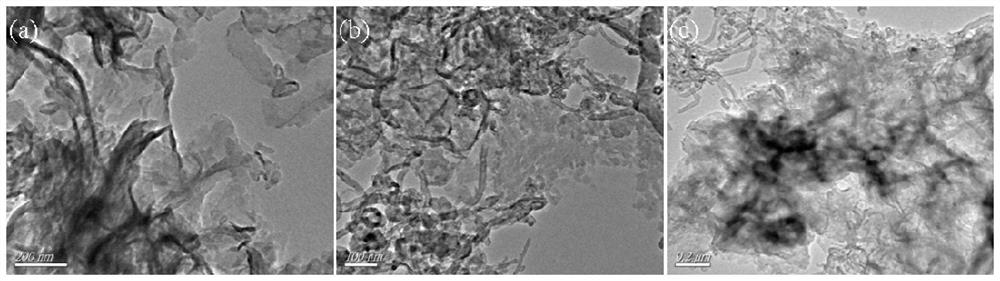

[0036] (2) Preparation of 2D-1D CN / MWNTs complex (CNM-3):

[0037] The CN and pretreated MWNTs were mixed and ground for 30 min at a ratio of 10:3, so that the CN and MWNTs were in uniform contact. The secondary calcination temperature was 500 °C, so that CN could connect with defects on the surface of MWNTs to form CNM-3 complexes during the further polycondensation process.

[0038] (3) Preparation of 2D-1D-2D CN / MWNTs / rGO (CNMC-1) composite:

[0039] 200 mg of the sample obtained in (2) and 2 mg of GO were added to 50 mL of deionized water, stirred vigorously for 10 min, hydrothermally reacted at 150 °C for 5 h, and finally washed, centrifuged and dried to obtain CNMC-1.

[0040] (4) Take 0.02g of the CNMC-1 composite photocatalyst in (3) and add it to the photochemical reaction i...

Embodiment 2

[0042] (1) MWNTs pretreatment: Add 1 g of MWNTs to 100 mL of concentrated nitric acid, heat and stir at 80 °C for 12 h, then centrifuge, wash and dry to obtain MWNTs with rich surface defects.

[0043] (2) Preparation of 2D-1D CN / MWNTs complex (CNM-3):

[0044] The CN and pretreated MWNTs were mixed and ground for 30 min at a ratio of 10:3, so that the CN and MWNTs were in uniform contact. The secondary calcination temperature was 500 °C, so that CN could connect with defects on the surface of MWNTs to form CNM-3 complexes during the further polycondensation process.

[0045] (3) Preparation of 2D-1D-2D CN / MWNTs / rGO (CNMC-2) composite:

[0046] 200 mg of the sample obtained in (2) and 6 mg of GO were added to 50 mL of deionized water, stirred vigorously for 10 min, hydrothermally reacted at 150 °C for 5 h, and finally CNMC-2 was obtained by washing, centrifuging and drying.

[0047] (4) Take 0.02g of the CNMC-2 composite photocatalyst in (3) and add it to the photochemical r...

Embodiment 3

[0049] (1) MWNTs pretreatment: Add 1 g of MWNTs to 100 mL of concentrated nitric acid, heat and stir at 80 °C for 12 h, then centrifuge, wash and dry to obtain MWNTs with rich surface defects.

[0050] (2) Preparation of 2D-1D CN / MWNTs complex (CNM-3):

[0051] The CN and pretreated MWNTs were mixed and ground for 30 min at a ratio of 10:3, so that the CN and MWNTs were in uniform contact. The secondary calcination temperature was 500 °C, so that CN could connect with defects on the surface of MWNTs to form CNM-3 complexes during the further polycondensation process.

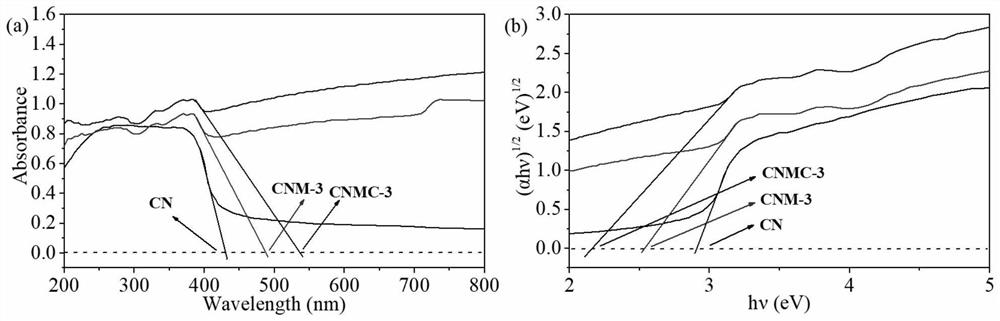

[0052] (3) Preparation of 2D-1D-2D CN / MWNTs / rGO (CNMC-3) composite:

[0053] 200 mg of the sample obtained in (2) and 10 mg of GO were added to 50 mL of deionized water, stirred vigorously for 10 min, hydrothermally reacted at 150 °C for 5 h, and finally CNMC-3 was obtained by washing, centrifuging and drying.

[0054] (4) Take 0.02g of the CNMC-3 composite photocatalyst in (3) and add it to the photochemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com