Large-diameter silo uniform discharging and coal blending device and method

A large-diameter, silo technology is applied in the field of large-diameter silos for uniform feeding and coal blending devices, and can solve the problem of small number of large-diameter silos, affecting coal blending accuracy, uniformity of coal crushing fineness, and coal particle size. And moisture segregation and other problems, to ensure particle size and moisture uniformity, prevent coke quality fluctuation phenomenon, prevent particle size and moisture segregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

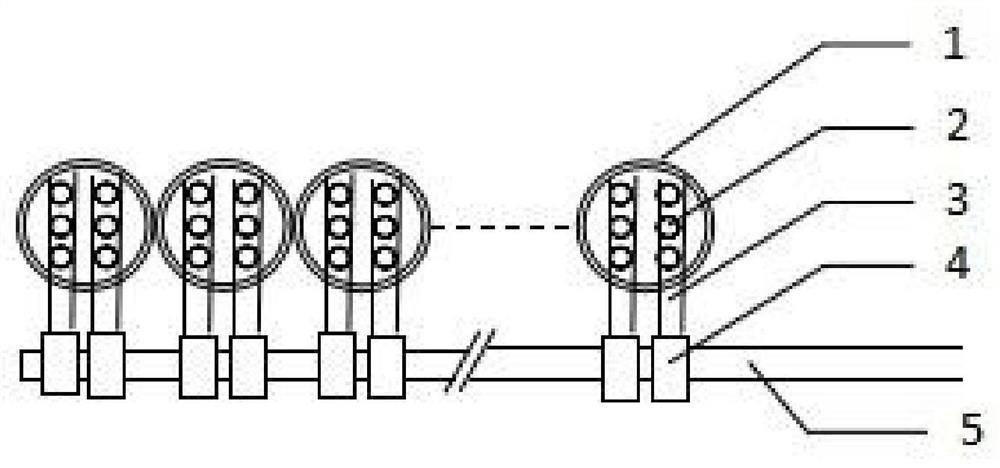

Embodiment 1

[0022] Embodiment one: if figure 2 , the coal blending belt 1 is located on one side of the multi-row parallel silo 1 matrix, and the bottom of the large-diameter silo 1 is provided with six discharge ports 2, and there are two rows at the bottom of the silo 1, and each row has three discharge ports 2 , the arrangement direction of the three feeding ports 2 in each row is perpendicular to the longitudinal direction of the silo 1 matrix, and the coal in the silos 1 in each longitudinal column can pass through two small belts-3 under the two rows of feeding ports 2 And the small belt 2 6 falls on the coal blending belt 1 5 at the transfer 4 of the respective belts, and the same amount of material feeding can be controlled at the same time to realize the uniform feeding and coal blending of the silo. The coal blending belt 1 5 and the silo 1 are connected Small belt one 3 and small belt two 6 and silo 1 form a coal blending unit.

Embodiment 2

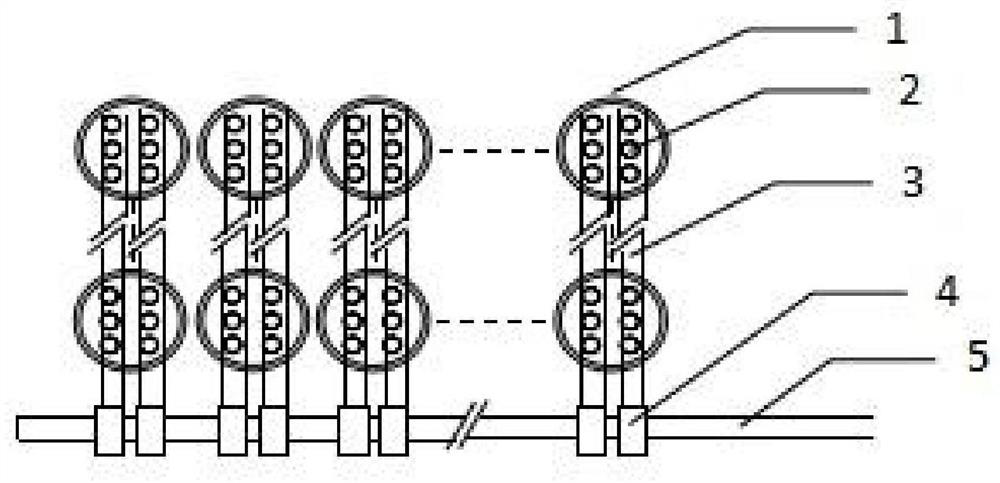

[0023] Embodiment two: if image 3 Coal blending belt 1 5 and coal blending belt 2 7 are located on both sides of the matrix lengthwise outside of the multi-row parallel silo 1. The large-diameter silo 1 has six feeding ports 2, which are arranged in two rows at the bottom of the silo 1. There are three feeding ports 2 in each row, and the arrangement direction of the three feeding ports 2 in each row is perpendicular to the longitudinal direction of the silo matrix. There are two small belts corresponding to the longitudinal row of each silo 1, which are respectively located in the two rows at the bottom of the silo. Below the discharge port, the coal in each longitudinal row of silos 1 can pass through the two small belts 1 3 and 2 6 below the two rows of discharge ports 2 and fall to the coal blending at the respective belt transfer 4. Belt 1 5, and the coal in each silo 1 falls on coal blending belt 1 5 and coal blending belt 2 7 through small belt 1 3 and small belt 2 6 f...

Embodiment 3

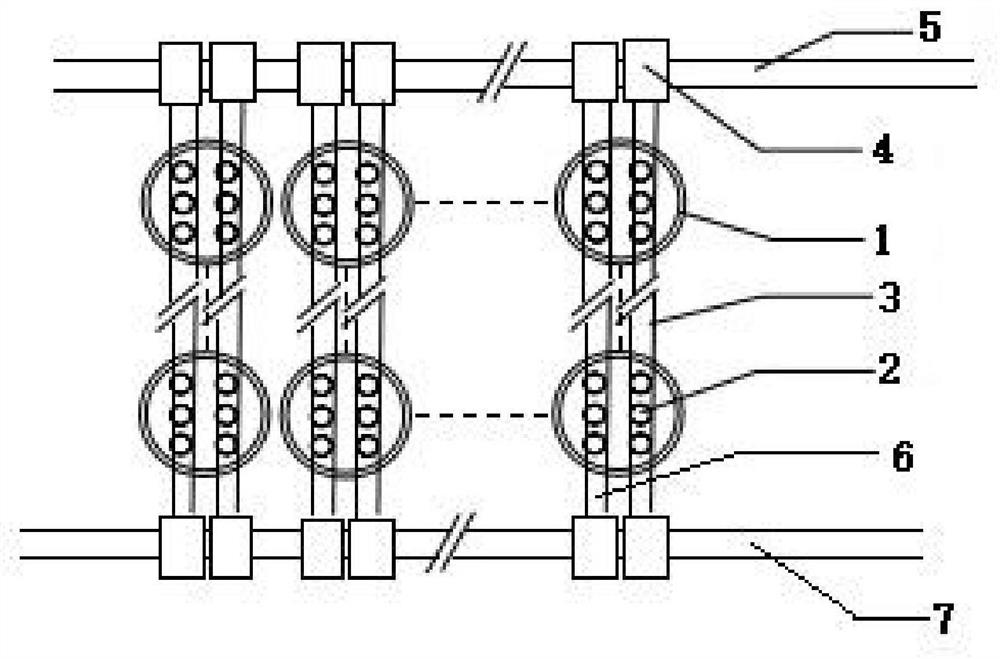

[0024] Embodiment three: as Figure 4 Coal blending belt 1 5 and coal blending belt 2 7 are located on both sides of the silo 1 matrix in the long direction. The large-diameter silo 1 has six feeding ports 2, which are arranged in two rows at the bottom of the silo 1, and each row has three The arrangement direction of three feeding ports 2 in each row is perpendicular to the longitudinal direction of the silo matrix. There are two small belts corresponding to the longitudinal column of each silo 1, which are respectively located in the two rows of feeding ports at the bottom of the silo. 2, the coal in each silo 1 can pass through the two small belts below it, and fall onto the two coal blending belts at the transfer point 2 of the respective belts for uniform coal blending; located in the matrix of silo 1 The coal blending belt one 5 and the coal blending belt two on the outer sides, the lower small belt one 3 and the small belt two 6 of the silo 1 and the silo 1 form a coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com