Application of tin disulfide/carbon nanofiber composite material in degradation of organic pollutants

A carbon nanofiber, organic pollutant technology, applied in water pollutants, chemical/physical processes, special compound water treatment, etc., can solve problems such as limiting photocatalytic activity, photogenerated electron-hole rapid recombination, etc. The effect of activity, specific surface area, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

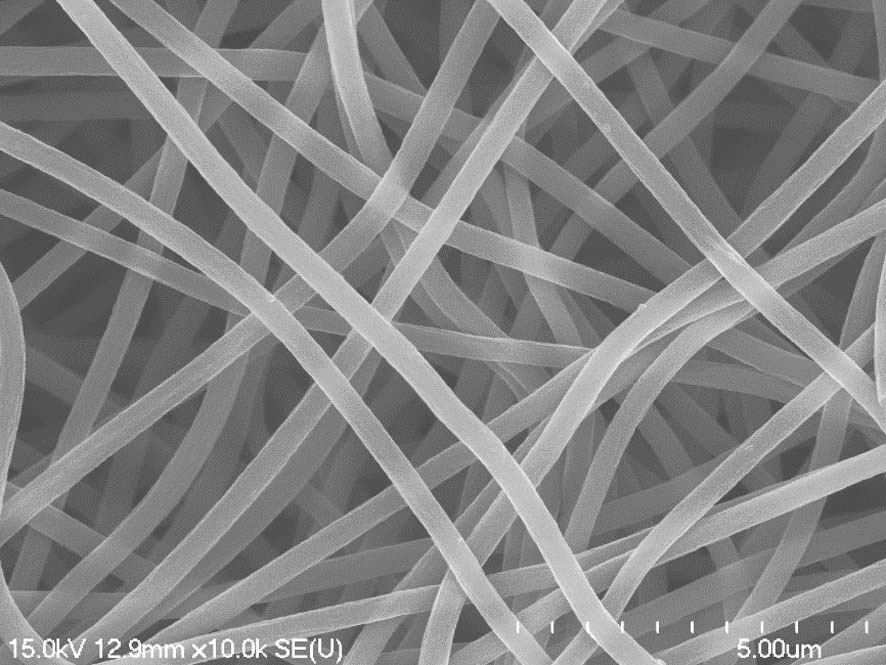

[0026] The preparation of carbon nanofibers, the specific steps are as follows:

Embodiment 2

[0030] SnS 2 / CNFs nanocomposite (0.25-SnS 2 / CNFs), the specific steps are as follows:

[0031] Weigh 87.7 mg (0.25 mol) SnCl 4 ·5H 2 O was dissolved in 20 mL of absolute ethanol and recorded as solution A. Weigh 150 mg (2 mol) CH 3 CSNH 2 Dissolve it in 20 mL of absolute ethanol, and record it as solution B. After mixing the two solutions of A and B evenly, pour them into the liner of a 50mL reactor, and put a piece of carbon nanofiber membrane (2×4cm 2 ) tilted into which the 120 o C for 12 hours, the product obtained was washed three times with deionized water and ethanol successively, and finally at 60 o C for 12 hours to obtain 0.25-SnS2 / CNFs nanocomposites.

Embodiment 3

[0033] SnS 2 / CNFs nanocomposite (0. 5-SnS 2 / CNFs), the specific steps are as follows:

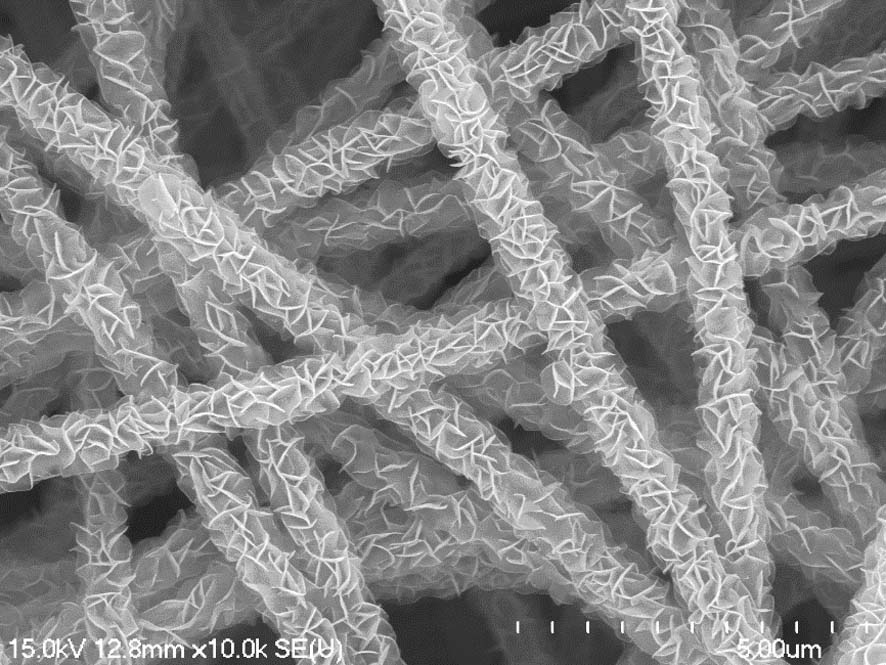

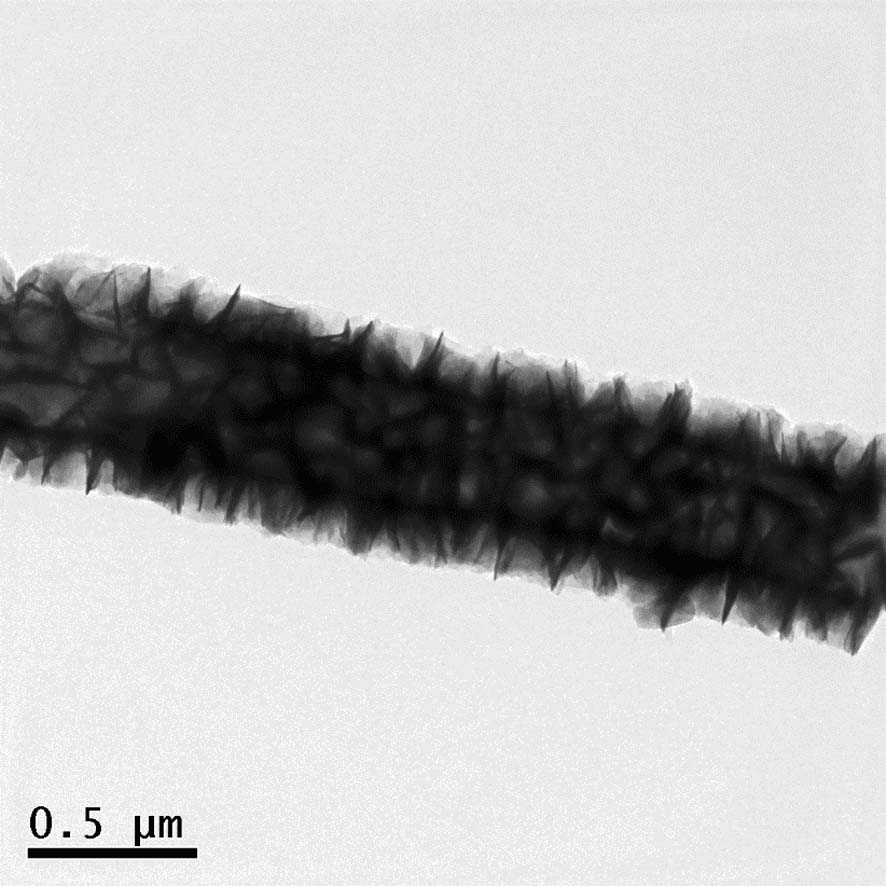

[0034] Weigh 175.3 mg (0.5mol) SnCl 4 ·5H 2 O was dissolved in 20 mL of absolute ethanol and recorded as solution A. Weigh out 150 mg (2 mol) CH 3 CSNH 2 Dissolve it in 20 mL of absolute ethanol, and record it as solution B. After the two solutions of A and B were mixed evenly, they were poured into a 50 mL reactor liner, and a piece of carbon nanofiber membrane (2×4cm 2 ) tilted into which the 120 o C for 12 hours, the product obtained was washed three times with deionized water and ethanol successively, and finally at 60 o C drying for 12 hours to obtain 0.5-SnS 2 / CNFs nanocomposites, SnS 2 The loading mass is 8 mg. attached figure 2 for the above 0.5-SnS 2 SEM images of / CNFs nanocomposites, attached image 3 for the above 0.5-SnS 2 TEM photo of CNFs nanocomposites; as can be seen from the figure, SnS 2 Nanosheets are evenly loaded on the surface of carbon nanofibers....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com