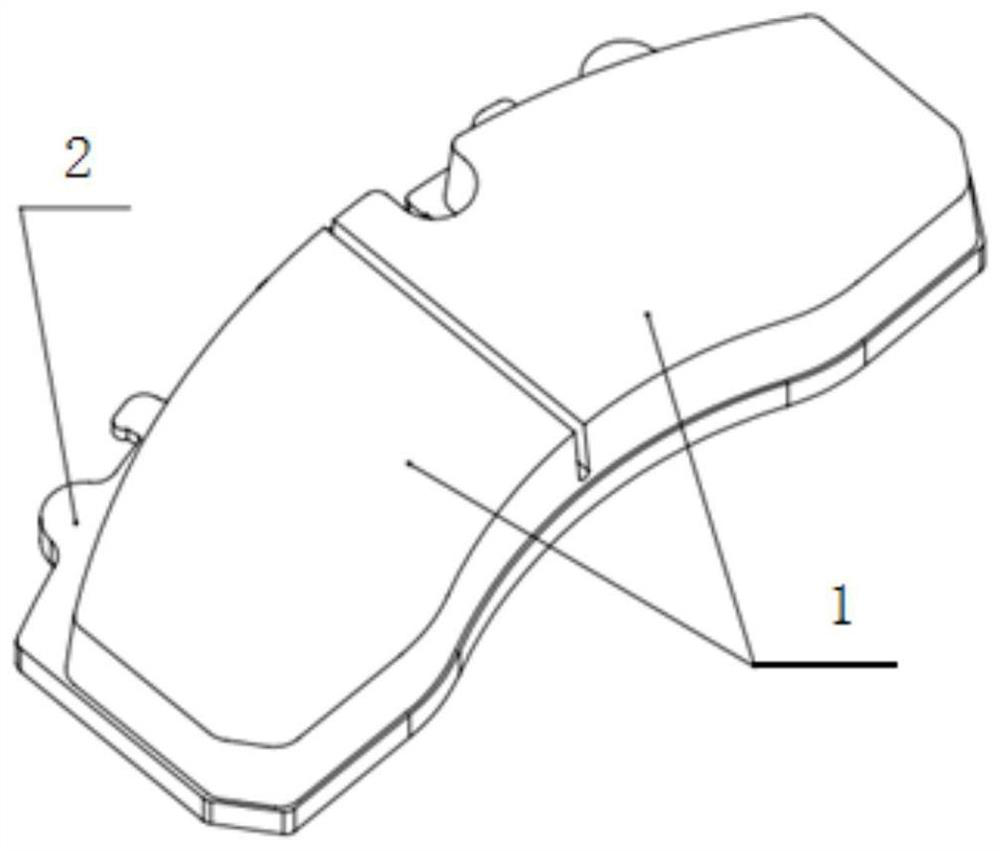

Friction material, friction body, brake pad comprising friction body, and preparation method and application of brake pad

A technology of friction materials and brake pads, which is applied in the field of brake pads and brake pads preparation, can solve the problems of easy falling off or delamination, large wear of brake discs, and insufficiently stable friction coefficient, etc., to ensure effectiveness and safety , Reduce maintenance costs, prolong the effect of maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

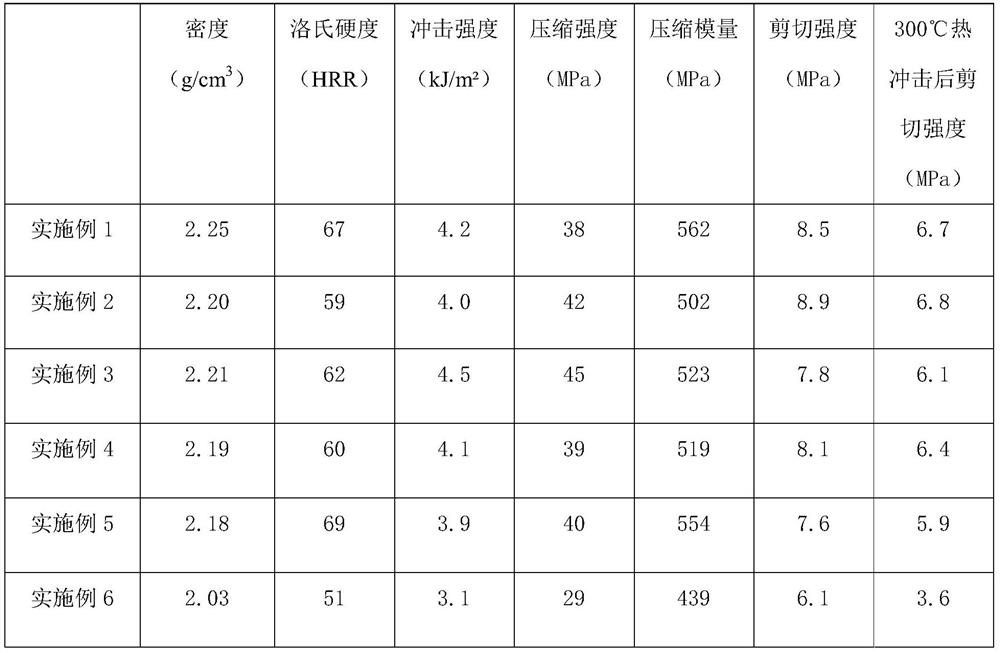

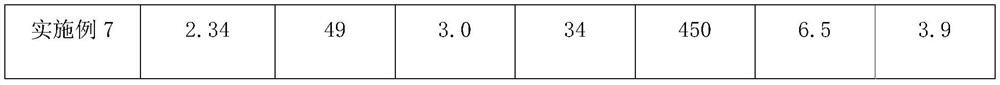

Embodiment 1

[0047] This embodiment provides a friction material, including the following raw materials: 800g of basalt fiber, 800g of stainless steel fiber, 1000g of chopped carbon fiber, 500g of polyacrylonitrile-based pre-oxidized wire, 1200g of diphenylmethane bismaleimide, powdered nitrile rubber 700g, calcined petroleum coke 1100g, flake graphite 1200g, conductive graphite 700g, copper oxide 400g, magnesium oxide 900g, light calcium carbonate 1400g; The length of described chopped carbon fiber is 3mm, and described diphenylmethane bismaleimide The mesh number is 800 mesh, the mesh number of the powdered nitrile rubber is 120 mesh, the mesh number of the flake graphite is 100 mesh, and the mesh number of the conductive graphite is 100 mesh.

[0048] The method for preparing a brake pad by using the above-mentioned friction material includes the following steps:

[0049] 1) Weigh the above-mentioned raw materials respectively, mix basalt fiber, stainless steel fiber, chopped carbon fib...

Embodiment 2

[0054] This embodiment provides a friction material, including the following raw materials: basalt fiber 500g, stainless steel fiber 1000g, chopped carbon fiber 500g, polyacrylonitrile-based pre-oxidized wire 500g, diphenylmethane bismaleimide 2000g, powdered nitrile rubber 500g, calcined petroleum coke 1500g, flake graphite 1000g, conductive graphite 1000g, copper oxide 300g, magnesium oxide 1400g, light calcium carbonate 1000g; The length of described chopped carbon fiber is 2mm, and described diphenylmethane bismaleimide The mesh number is 700 mesh, the mesh number of the powdered nitrile rubber is 140 mesh, the mesh number of the flake graphite is 80 mesh, and the mesh number of the conductive graphite is 120 mesh.

[0055] The method for preparing a brake pad by using the above-mentioned friction material includes the following steps:

[0056] 1) Weigh the above-mentioned raw materials respectively, first mix basalt fiber, stainless steel fiber, chopped carbon fiber, poly...

Embodiment 3

[0061] This embodiment provides a friction material, including the following raw materials: 1200g of basalt fiber, 500g of stainless steel fiber, 1000g of chopped carbon fiber, 1000g of polyacrylonitrile-based pre-oxidized wire, 500g of diphenylmethane bismaleimide, powdered nitrile rubber 1200g, calcined petroleum coke 800g, flake graphite 2000g, conductive graphite 500g, copper oxide 500g, magnesium oxide 700g, light calcium carbonate 2000g; The length of described chopped carbon fiber is 4mm, and described diphenylmethane bismaleimide The mesh number is 800 mesh, the mesh number of the powdered nitrile rubber is 100 mesh, the mesh number of the flake graphite is 120 mesh, and the mesh number of the conductive graphite is 80 mesh.

[0062] The method for preparing a brake pad by using the above-mentioned friction material includes the following steps:

[0063] 1) Weigh the above raw materials respectively, mix basalt fiber, stainless steel fiber, chopped carbon fiber, polyac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com