Preparation method of mold bottom brick for high-temperature alloy steel ingot mold

A technology of high-temperature alloy steel and mold bottom bricks, applied in the field of refractory materials, can solve problems such as troublesome handling of steel ingots, pollution of molten steel, and easy erosion, and achieve the effects of not sticking to bricks, improving the quality of high-temperature alloys, and smoothing the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

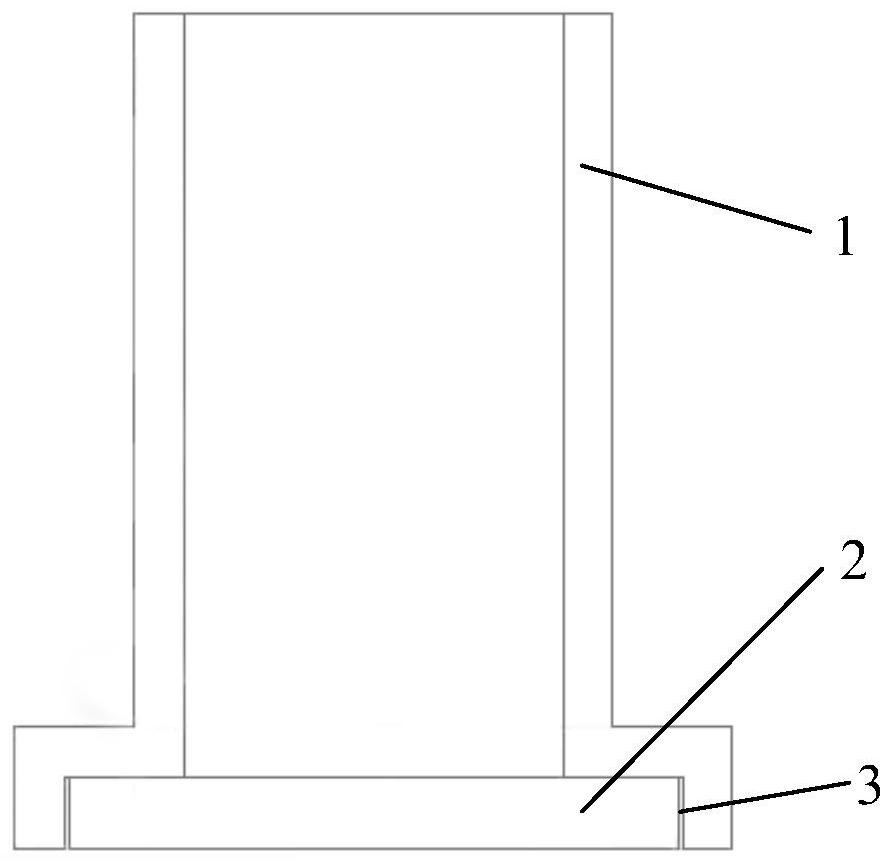

Image

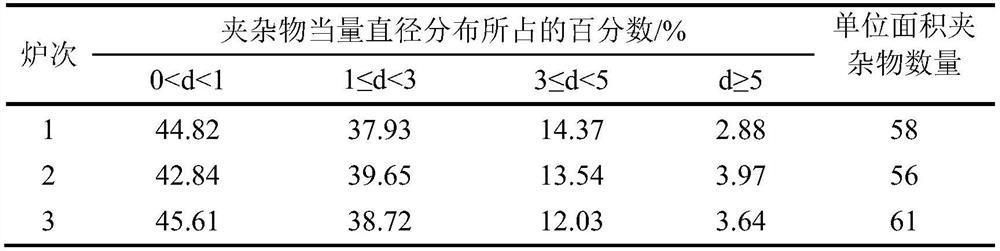

Examples

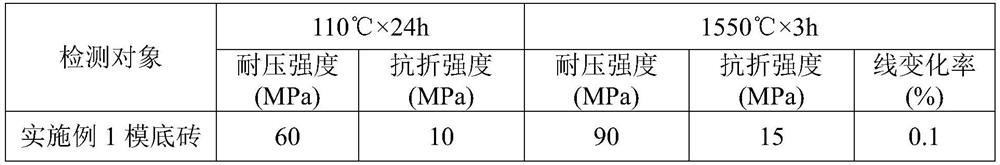

Embodiment 1

[0022] A method for preparing a mold bottom brick for a high-temperature alloy steel ingot mold, wherein the mold bottom brick is uniformly coated with a paint with a thickness of 0.5 to 1 mm, specifically comprising the following steps: firstly making the mold bottom brick, and then making the coating for the mold bottom brick , and then evenly coat the paint on the use surface of the mold bottom brick, and then put the mold bottom brick in a heating furnace to bake, and it can be used after drying.

[0023] (1) Preparation of mold bottom bricks: put 35% white corundum, 32% fused mullite, 28% alumina powder, and 5% bonded clay into a ball mill for ball milling. When the particle size of the powder is less than 5 μm, the grinding is completed, and then Put the powder into the mold and keep it under the temperature of 1380°C and the pressure of 35MPa for 2 hours to obtain the corundum-mullite mold bottom brick, and the outer diameter tolerance of the mold bottom brick formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com