Vacuum pump coating with good wear resistance and preparation method thereof

A vacuum pump and coating technology, which is applied in the direction of coating, metal-free paint, etc., can solve the problems of wear resistance, poor durability, and reduced service life of vacuum pumps, etc., to achieve strong durability and high durability , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A vacuum pump coating with good wear resistance, comprising the following raw materials in parts by weight: 20 parts of cobalt, 10 parts of boron, 15 parts of titanium, 15 parts of carbon, 10 parts of chromium, 7 parts of potassium, 9 parts of sodium, 12 parts of nickel, 17 parts of copper, 15 parts of silicon, 7 parts of hafnium, 5 parts of zirconium, 4 parts of lanthanum, 30 parts of yttrium oxide, 15 parts of rare earth chloride, 10 parts of tetrahydrofuran, 30 parts of absolute ethanol, 20 parts of dilute hydrochloric acid.

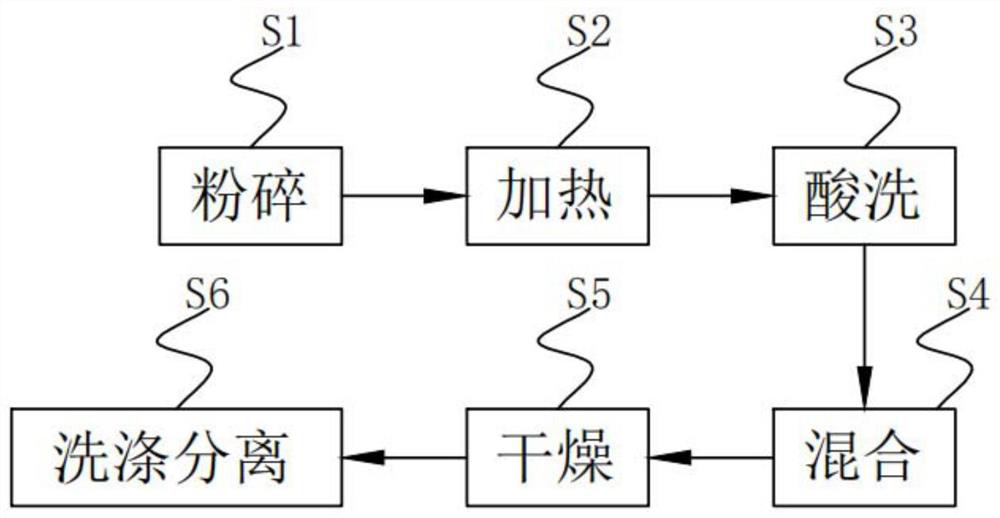

[0027] see figure 1 A method for preparing a vacuum pump coating with good wear resistance, comprising the steps of:

[0028] S1, crushing: add cobalt, boron, titanium, carbon, chromium, potassium, sodium, nickel, copper, silicon, hafnium, zirconium, lanthanum, yttrium oxide, and rare earth chloride into the first mixer according to the above weight parts for crushing and Mixing and grinding, stirring for 4 minutes at a rotating ...

Embodiment 2

[0035] The difference between embodiment 2 and embodiment 1 is that the content of its internal components is different, and its preparation method is also adjusted adaptively according to the content of its components. A vacuum pump coating with good anti-wear performance and its preparation method include the following Raw materials in parts by weight: 21 parts of cobalt, 11 parts of boron, 16 parts of titanium, 16 parts of carbon, 11 parts of chromium, 8 parts of potassium, 10 parts of sodium, 13 parts of nickel, 18 parts of copper, 17 parts of silicon, 8 parts of hafnium, zirconium 7 parts, lanthanum 5 parts, yttrium oxide 35 parts, rare earth chloride 16 parts, tetrahydrofuran 11 parts, absolute ethanol 32 parts, dilute hydrochloric acid 22 parts.

Embodiment 3

[0037]The difference between Example 3 and Example is that the content of its internal components is different, and its preparation method is also adjusted adaptively according to the content of its components. A vacuum pump coating with good anti-wear performance and its preparation method include the following weight Parts of raw materials: 22 parts of cobalt, 12 parts of boron, 17 parts of titanium, 17 parts of carbon, 15 parts of chromium, 10 parts of potassium, 12 parts of sodium, 14 parts of nickel, 20 parts of copper, 18 parts of silicon, 9 parts of hafnium, 8 parts of zirconium 6 parts of lanthanum, 40 parts of yttrium oxide, 20 parts of rare earth chloride, 12 parts of tetrahydrofuran, 34 parts of absolute ethanol, and 25 parts of dilute hydrochloric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com