Mining downward drilling, water draining, slag discharging and extraction integrated equipment and gas extraction method

A technology of gas drainage and drainage, applied in the field of gas drainage equipment, can solve the problems of increasing the probability of coal and gas outburst, reducing the moisture in the hole, and the inability to extract gas, so as to improve the utilization rate of products and reduce the moisture in the hole , Eliminate the effect of water seal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

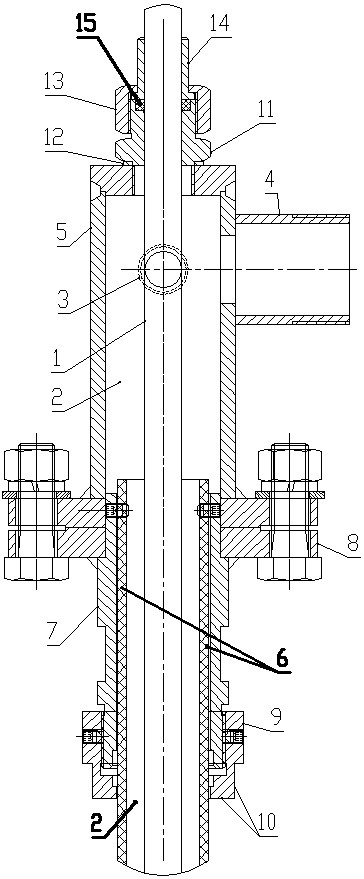

[0034] Such as figure 1 As shown, the mining integrated equipment for drainage and slag discharge for mines of the present invention includes a drainage pipe for extending into the gas drainage hole under the coal seam, and the lower end of the drainage pipe (inner pipe 6) is open; The coaxial line sleeve in the production pipe is provided with a central pipe 1 for water injection and gas injection to improve air permeability, and the lower end of the central pipe 1 is located at the bottom of the extraction pipe; the bottom of the side wall of the extraction pipe is uniformly provided with a plurality of extraction holes for gas extraction , the central pipe 1 and the extraction pipe form a ring-shaped extraction cavity 2, and the top of the side wall of the extraction tube is provided with an extraction interface 3 and a slag discharge interface 4, both of which are connected to the extraction The cavity 2 is connected, the drainage interface 3 is used to connect the gas dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com