Interstage sealing device for gas compressor and turbine rotor of small gas turbine

A technology for turbine rotors and gas turbines, which is applied in the direction of gas turbine devices, jet propulsion devices, components of pumping devices for elastic fluids, etc. It can solve problems such as inapplicability, and achieve the effects of easy assembly, effective and reliable sealing, and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

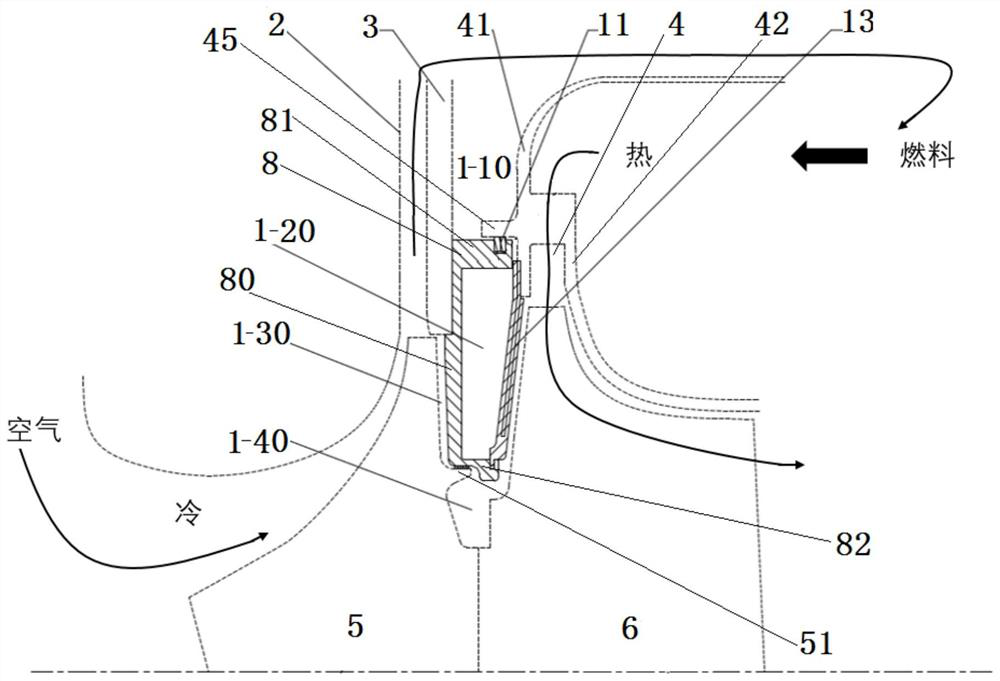

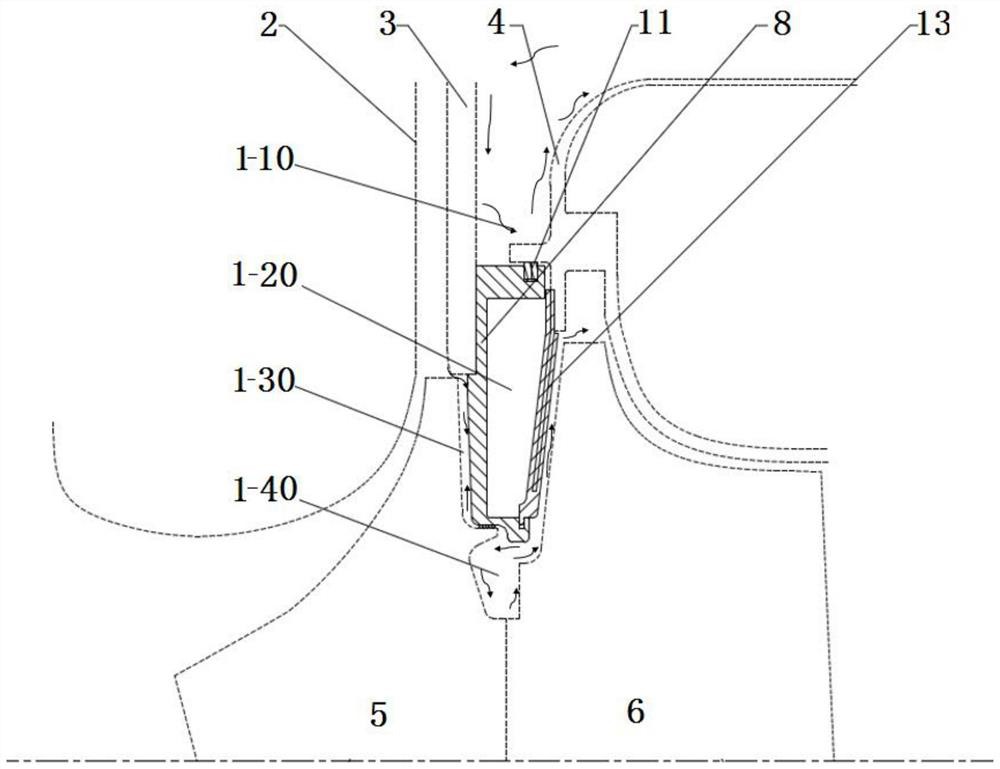

[0052] Such as figure 1 , figure 2 As shown, the diffuser 3, the sealing ring 8, and the nozzle ring 4 of the combustion chamber of the interstage sealing device of the small gas turbine compressor and the turbine rotor are all annular;

[0053] Diffuser 3, sealing ring 8, combustion chamber nozzle ring 4 are coaxially assembled with compressor impeller 5 and turbine rotor 6;

[0054] The diffuser 3 is fixed in the diffuser casing 2, and a radial cold air passage is formed between the front side of the diffuser 3 and the diffuser casing 2;

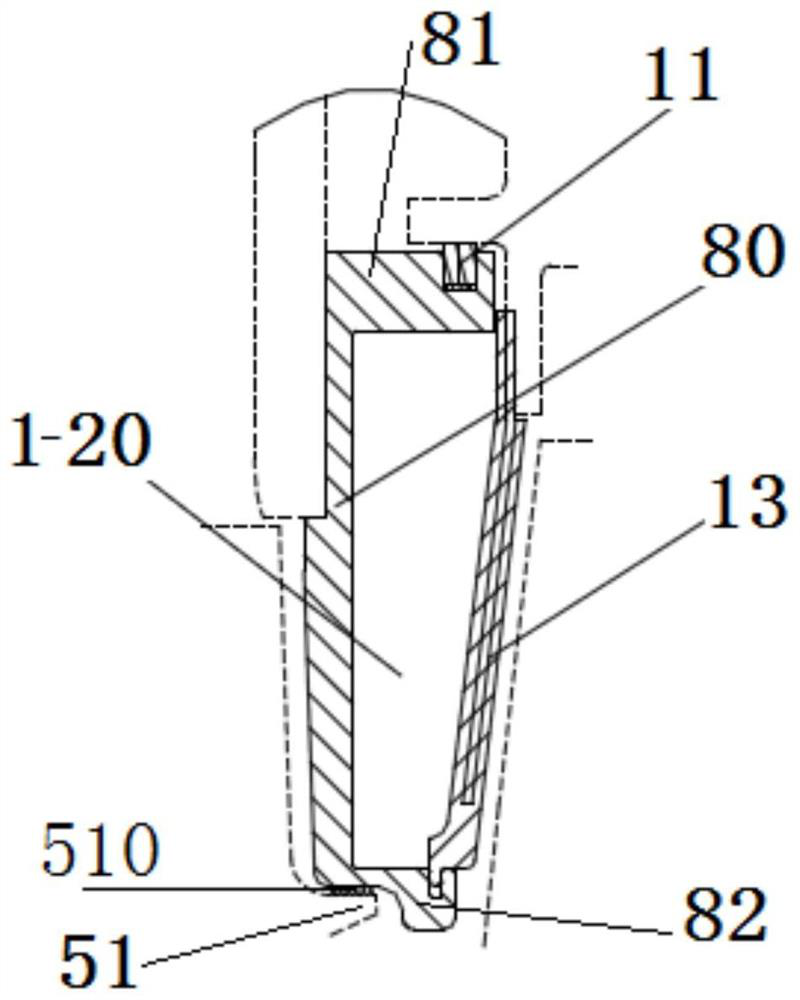

[0055] Such as image 3 As shown, the rear side of the front end wall 80 of the sealing ring 8 is formed with a coaxial far-axis ring wall 81 and a near-axis ring wall 82;

[0056] A ring of heat insulating tiles 13 is installed between the rear ends of the far-axis ring wall 81 and the near-axis ring wall 82;

[0057] The front end wall 80 of the sealing ring 8, the far-axis ring wall 81, the near-axis ring wall 82 and the heat insul...

Embodiment 2

[0070] Based on the interstage sealing device between a small gas turbine compressor and a turbine rotor in Embodiment 1, a piston ring installation groove is formed in the circumferential direction at the rear end of the far-axis ring wall 81 of the seal ring 8;

[0071] Piston ring 11 is assembled to the piston ring installation groove;

[0072] The combustion chamber nozzle ring 4 includes an outer nozzle ring 41 and an inner nozzle ring 42;

[0073] The front part of the outer nozzle ring 41 is bent radially inward, and the rear part is bent axially backward;

[0074] The front part of the inner nozzle ring 42 is bent radially outward, and the rear part is bent axially backward;

[0075] The inner nozzle ring 42 and the outer nozzle ring 41 form a hot gas injection channel;

[0076] The front end of the outer nozzle ring 41 is formed with an outer spacer ring 45 protruding forward;

[0077] The front end of the outer isolation ring 45 is sleeved outside the rear end of ...

Embodiment 3

[0080] Based on the interstage sealing device between the small gas turbine compressor and the turbine rotor in Embodiment 1, the heat insulating tile 13 is fan-shaped;

[0081] The two wings of the insulation tile 13 are respectively provided with grooves and raised ribs;

[0082] A plurality of heat-insulating tiles 13 cooperate with the ribs through the grooves, and connect end to end to form a complete sealing ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com