BSI process deep trench isolation manufacturing method

A technology of deep trench isolation and manufacturing method, which is applied in radiation control devices, electrical components, diodes, etc., and can solve problems such as increased random telegraph noise, large plasma damage, increased dark current, and white-spot pixels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

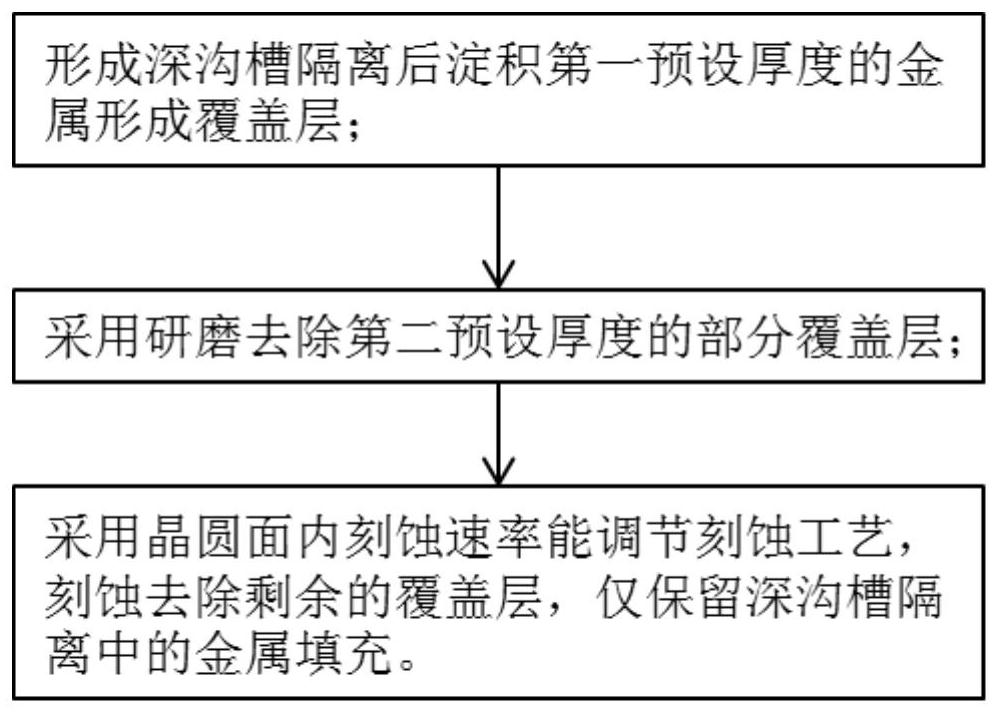

[0026] The first embodiment, such as figure 1 As shown, the present invention provides a BSI process deep trench isolation manufacturing method, which can be applied in the BSI process of 55nm, comprising the following steps:

[0027] S1, after forming the deep trench isolation by etching, deposit a metal with a first predetermined thickness by PVD process, fill the deep trench isolation and form a covering layer on the surface and both sides of the deep trench isolation;

[0028] S2, using grinding to remove part of the covering layer with a second preset thickness;

[0029] S3, etching to remove the remaining cover layer, leaving only the metal filling in the deep trench isolation;

[0030] Wherein, when implementing step S3, the etching rate in the wafer plane can be adjusted.

no. 2 example

[0031] In the second embodiment, the present invention provides a BSI process deep trench isolation manufacturing method, which can be applied to a 55nm BSI process, including the following steps:

[0032] S1, after forming the deep trench isolation by etching, deposit metal tungsten with a first predetermined thickness by PVD process, fill the deep trench isolation and form a covering layer on the surface and both sides of the deep trench isolation;

[0033] S2, using chemical mechanical grinding to remove part of the covering layer with a second preset thickness;

[0034] S3, the remaining cover layer is removed by plasma etching, and only the metal filling in the deep trench isolation is reserved.

no. 3 example

[0035] In the third embodiment, the present invention provides a BSI process deep trench isolation manufacturing method, which can be applied to a 55nm BSI process, including the following steps:

[0036] S1, after etching to form deep trench isolation, deposit metal tungsten with a thickness of 2000-4000 angstroms by PVD process, fill the deep trench isolation and form a covering layer on the surface and both sides of the deep trench isolation;

[0037] S2, using chemical mechanical grinding to remove part of the covering layer with a thickness of 500 angstroms-2500 angstroms;

[0038] S3, using plasma etching to remove the remaining cover layer, leaving only the metal filling in the deep trench isolation.

[0039] To further improve the third embodiment above, in step S1, the preferred thickness of metal tungsten deposited by PVD process after etching to form deep trench isolation is 2000 angstroms, 2100 angstroms, 2200 angstroms, 2300 angstroms, 2400 angstroms, 2500 angstro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com