Forming machine convenient for the preparation of semiconductor graphite and its preparation method

A semiconductor and forming machine technology, applied in the direction of material forming presses, chemical instruments and methods, presses, etc., can solve problems such as strong singleness, excessive graphite powder, and difficulty in cutting graphite powder, and achieve the goal of reducing waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

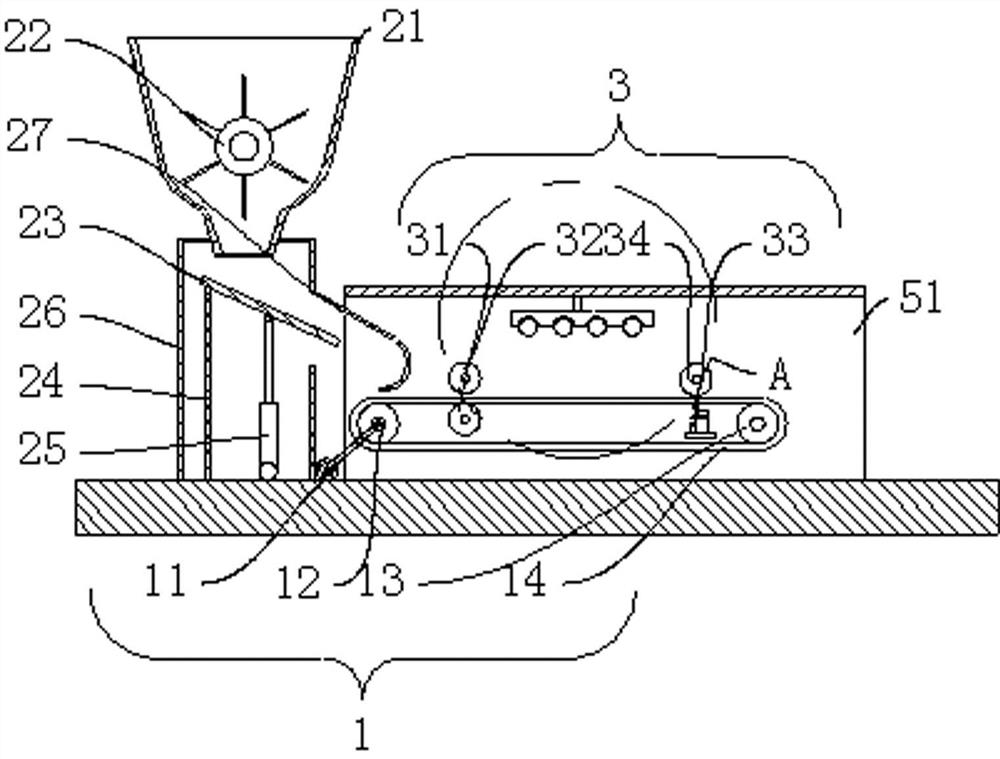

[0031] see Figure 1-5 , the molding machine for the preparation of semiconductor graphite provided by the embodiment of the present invention includes a driving mechanism 1, a feeding mechanism 2, a molding mechanism 3, a heating mechanism 4 and a base 5, and the feeding mechanism 2 is fixedly arranged on the bottom of the base 5. At one end, the driving mechanism 1 is fixedly arranged in the middle of the base 5 , the heating mechanism 4 is fixedly arranged above the driving mechanism 1 , and the molding mechanism 3 is fixedly arranged below the heating mechanism 4 ;

[0032] The feeding mechanism 2 includes a feeding hopper 21, a stirring wheel 22, a blanking plate 23, a support rod 24, a telescopic rod 25, a fixed frame 26 and a baffle plate 27. The fixed frame 26 is a rectangular structure, and the fixed The frame 26 is fixedly arranged on the base 5, the fixed frame 26 is provided with an opening, the feeding hopper 21 is fixedly arranged on the upper end of the fixed fr...

Embodiment 2

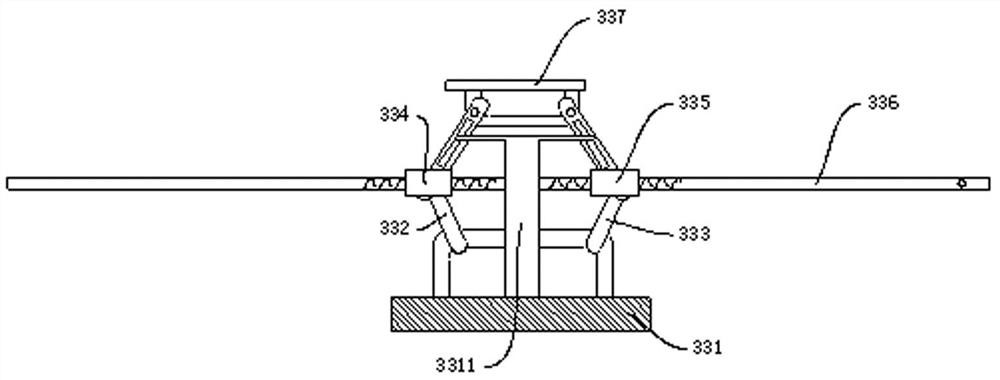

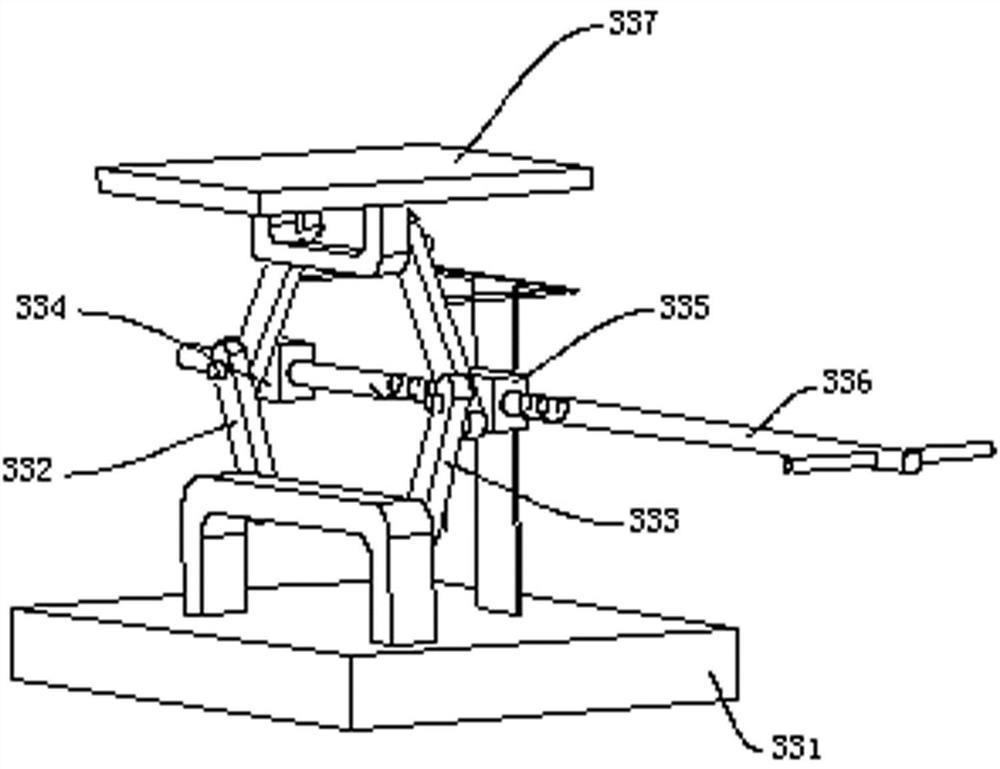

[0035] In the first embodiment, there is still a problem that the specification of the initially formed plate cannot be changed. Therefore, on the basis of the first embodiment, this embodiment further includes: the driving mechanism 1 includes a driving motor 11, a first round roller 12. The second round roller 13 and the conveyor belt 14, the drive motor 11 is fixedly arranged on the base 5, the output end of the drive motor 11 is provided with a coupling, and the coupling is connected to the first The round rollers 12 are connected to each other, a vertically installed support plate 51 is fixed on the base 5 , the first round roller 12 is rotatably arranged on the connecting rod, and the connecting rod is fixedly arranged on the support plate 51 . On one side, the second round roller 13 is rotatably arranged on the connecting rod, the connecting rod is fixedly arranged on one side of the support plate 51, and the transmission belt is sleeved on the first round roller 12 and ...

Embodiment 3

[0040] see figure 1 , in this embodiment, the present invention also proposes a preparation method of a molding machine that is convenient for the preparation of semiconductor graphite, comprising the following steps:

[0041] Step 1, put the graphite powder into the device from the feeding hopper 21, start the stirring wheel 22 to stir the graphite powder, further, the graphite powder will fall on the blanking plate 23, according to the graphite powder. In the case of fluidity, the telescopic rod 25 is stretched upward or downward, so that the graphite powder can fall onto the conveyor belt 14;

[0042] In step 2, the drive motor 11 is started, and further, the first round roller 12 is driven to rotate, which in turn drives the conveyor belt 14 to rotate, and the graphite powder falling on the conveyor belt 14 passes through the first pressure roller. 31 and the second pressure roller 32, the graphite powder will be rolled to form a material layer of a certain thickness;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com