Preparation method of professional molecular sieve desiccant for brake system

A brake system and molecular sieve technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of large size and quality differences of formed particles, limited natural zeolite resources, high cost, etc., and achieve good wear rate and high adsorption capacity. High, dimensionally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

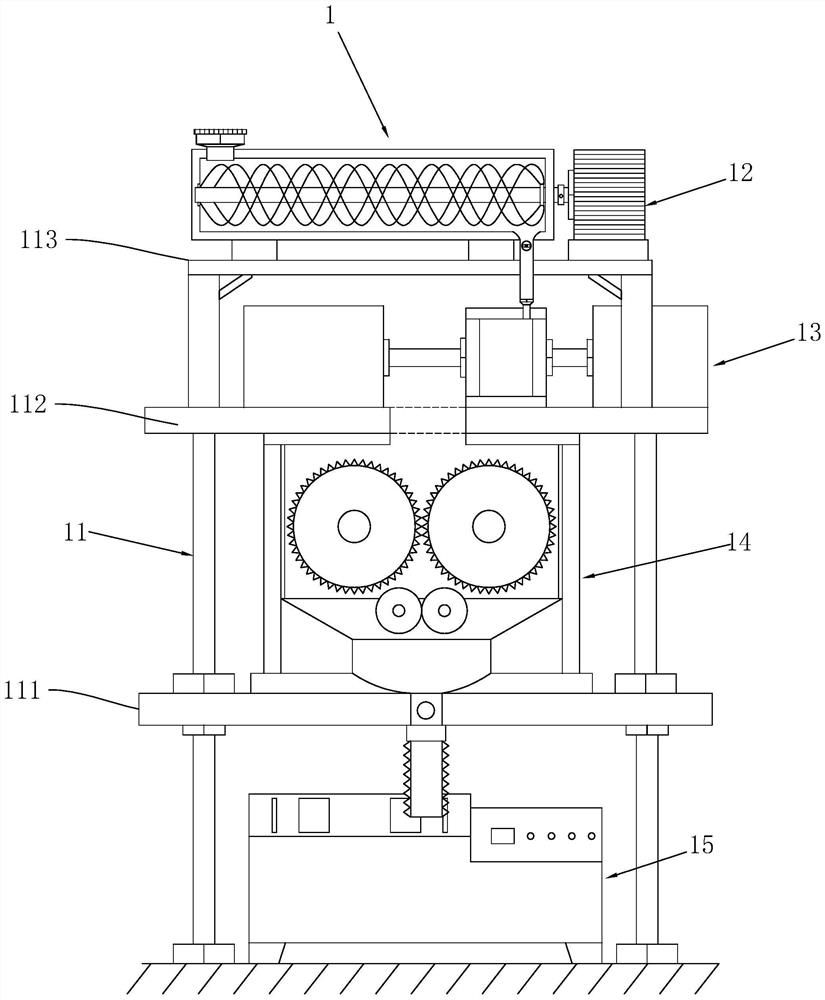

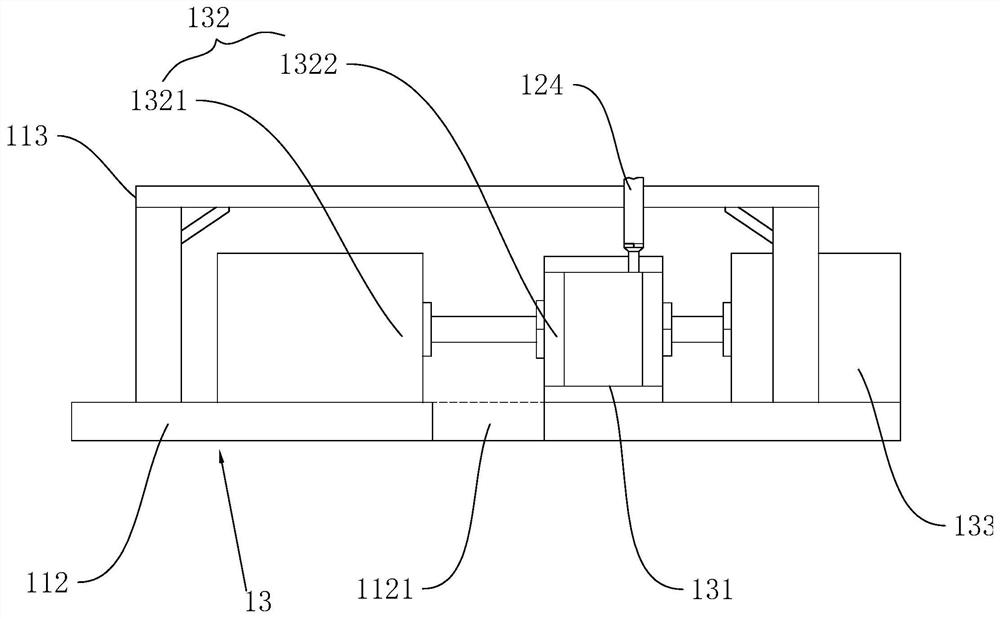

[0054] refer to figure 1 , the equipment required for the preparation of a professional molecular sieve desiccant for a brake system disclosed in the present application, including a premixing device 1, which includes a three-layer structure bracket 11, a premixing mechanism 12, a compression mechanism 13, a crushing Mechanism 14 and ball milling mechanism 15, the support 11 is formed with the first placement layer 111, the second placement layer 112 and the third placement layer 113 from bottom to top; Communication; the compression mechanism 13 is fixedly connected to the second placement layer 112 and communicates with the crushing mechanism 14; the crushing mechanism 14 is fixedly connected to the first placement layer 111 and can communicate with the ball mill mechanism 15; the ball mill mechanism 15 is arranged on the ground, and the ball mill mechanism 15 is a planetary ball mill.

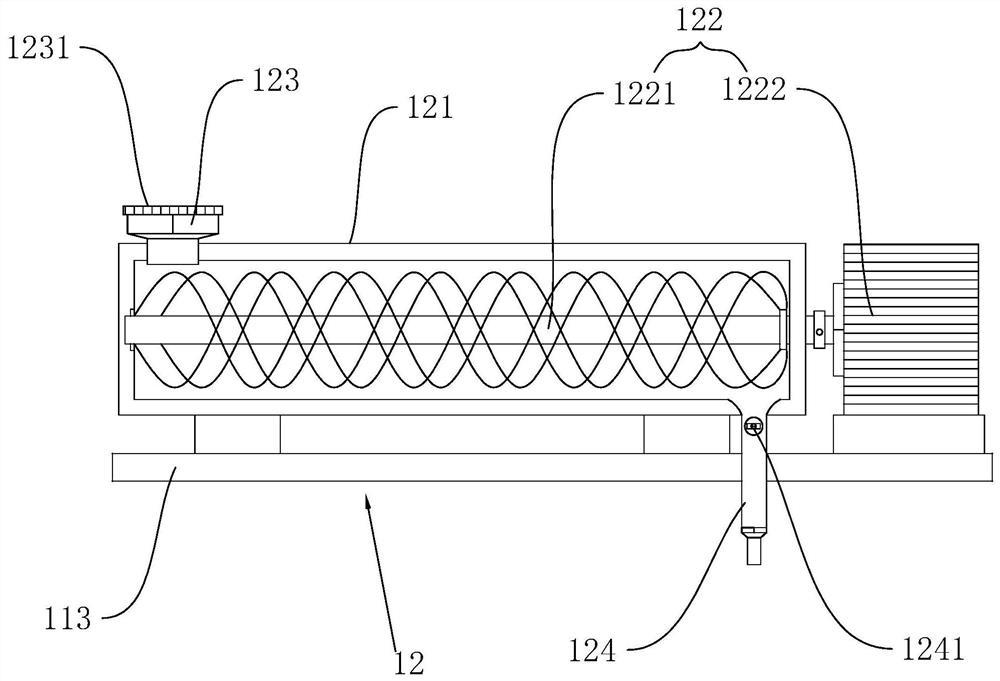

[0055] refer to figure 1 and figure 2 , the pre-mixing mechanism 12 includes a mixin...

Embodiment 2

[0082] The difference between Example 2 and Example 1 is: step 1.1, raw material pretreatment: select kaolin with a SiO2 / Al2O3 molar ratio of 2.08 for crushing treatment, and use a 600-mesh sieve to sieve kaolin with a fineness of 23 μm.

Embodiment 3

[0084]The difference between Example 3 and Example 1 is: step 1.1, raw material pretreatment: select kaolin with a SiO2 / Al2O3 molar ratio of 2.08 for crushing, and use a 1340-mesh sieve to sieve kaolin with a fineness of 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com