Seawater desalination device based on rotary gas hydrate separation method

A rotary separation and hydrate technology, applied in seawater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., to save energy, improve efficiency, and concentrate and compact functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

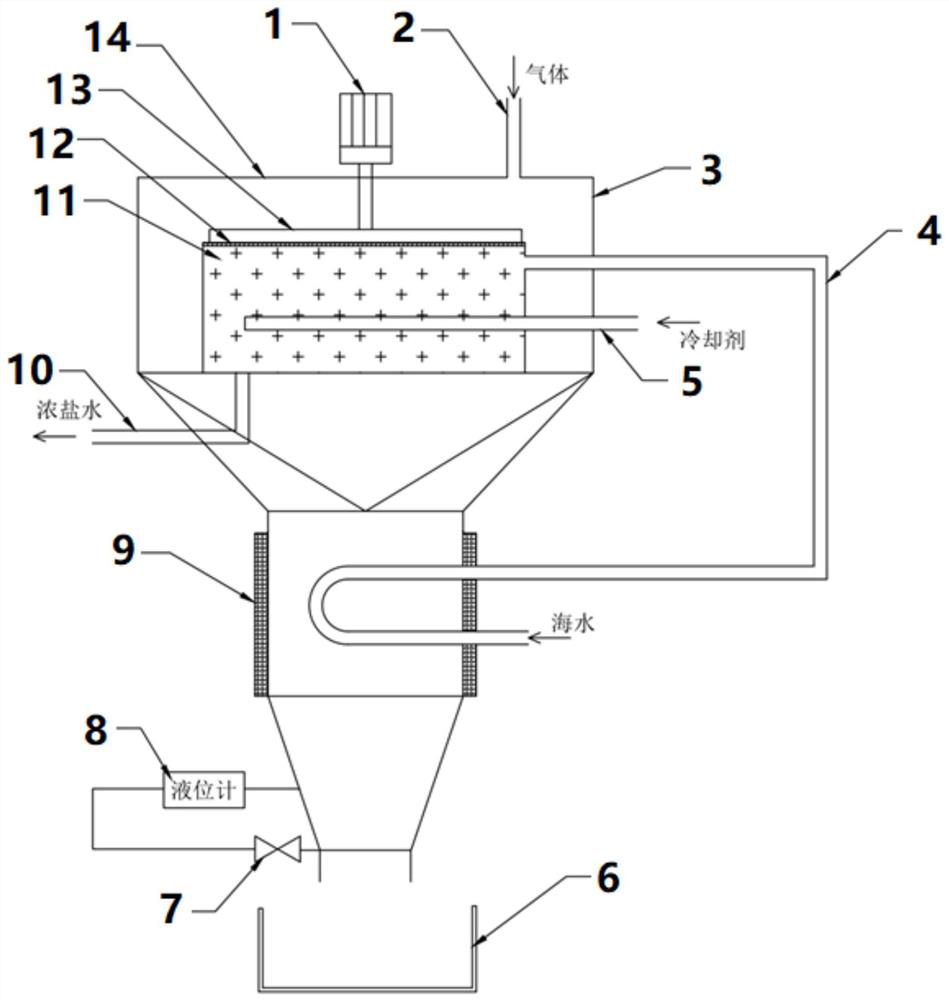

[0017] Embodiment one, refer to figure 1 , this embodiment proposes a seawater desalination device based on the rotary separation of gas hydrate method, which is connected according to the device structure, and the specific steps are as follows:

[0018] (1) Preparation: Open the upper cover 14 of the stainless steel container 3, fill or clean the cylindrical porous medium 11 into the stainless steel container 3, the residual liquid is discharged from the water outlet 10, and the installation scraper 13 stays at the initial position, that is, paste and round Metal mesh 5 surface;

[0019] (2) Water intake: After the device is vacuumed and leak detected, an appropriate amount of seawater is passed into the cylindrical porous medium 11 until the pores are saturated, and the coolant is passed into the cooling pipe 5 to provide a supply for hydrate formation. After the temperature is stabilized at low temperature, gas is introduced into the gas inlet 2 to reach the hydrate phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com