Petrochemical industry circulating sewage and RO concentrated water treatment system and wastewater treatment process

A technology of circulating sewage and treatment system, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of low biochemical efficiency, achieve no sludge generation, and have strong impact resistance , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

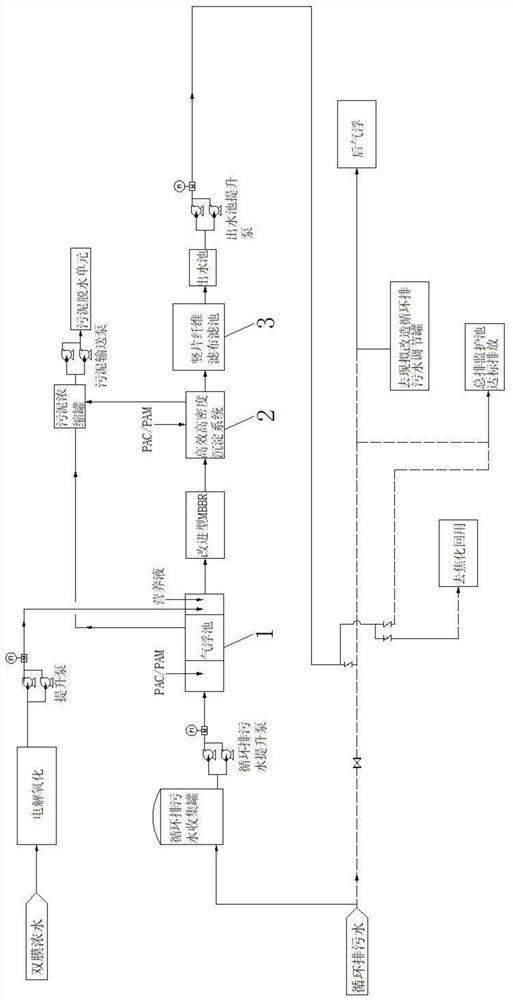

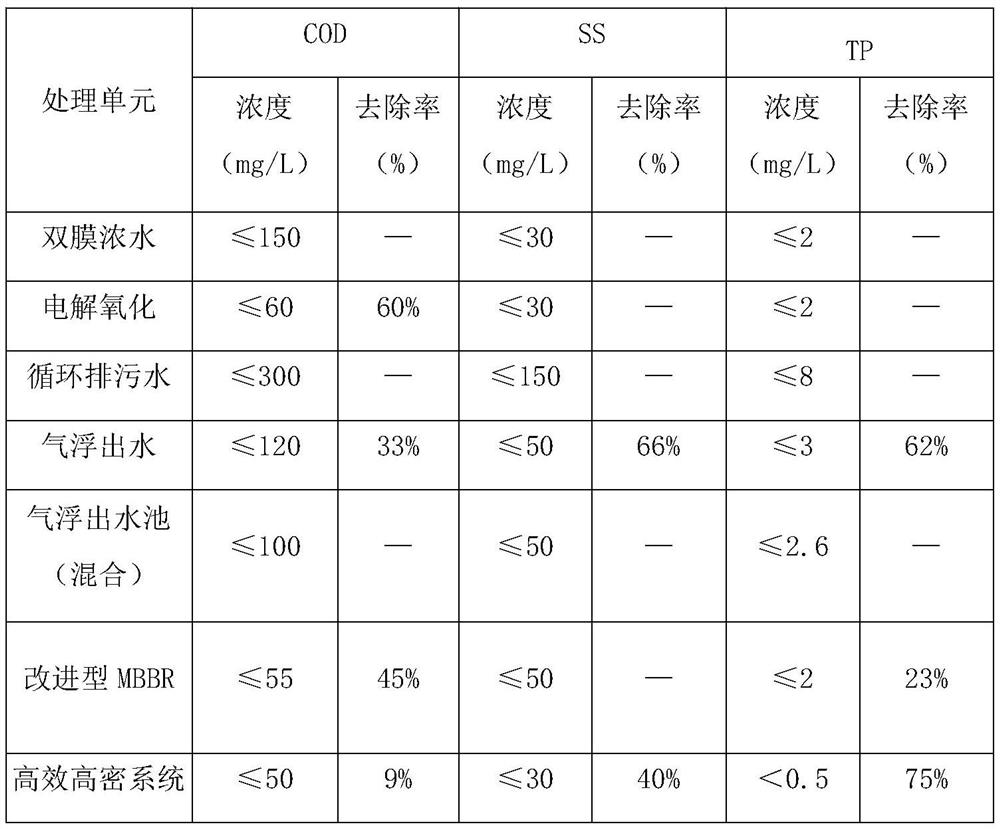

[0048] A petrochemical water plant built a new circulating sewage and RO concentrated water treatment station, the treatment scale is 250m of circulating sewage 3 / h, RO concentrated water volume is 150m 3 / h, all kinds of wastewater influent COD ≤ 300mg / L, SS ≤ 200mg / L, total phosphorus ≤ 6mg / L.

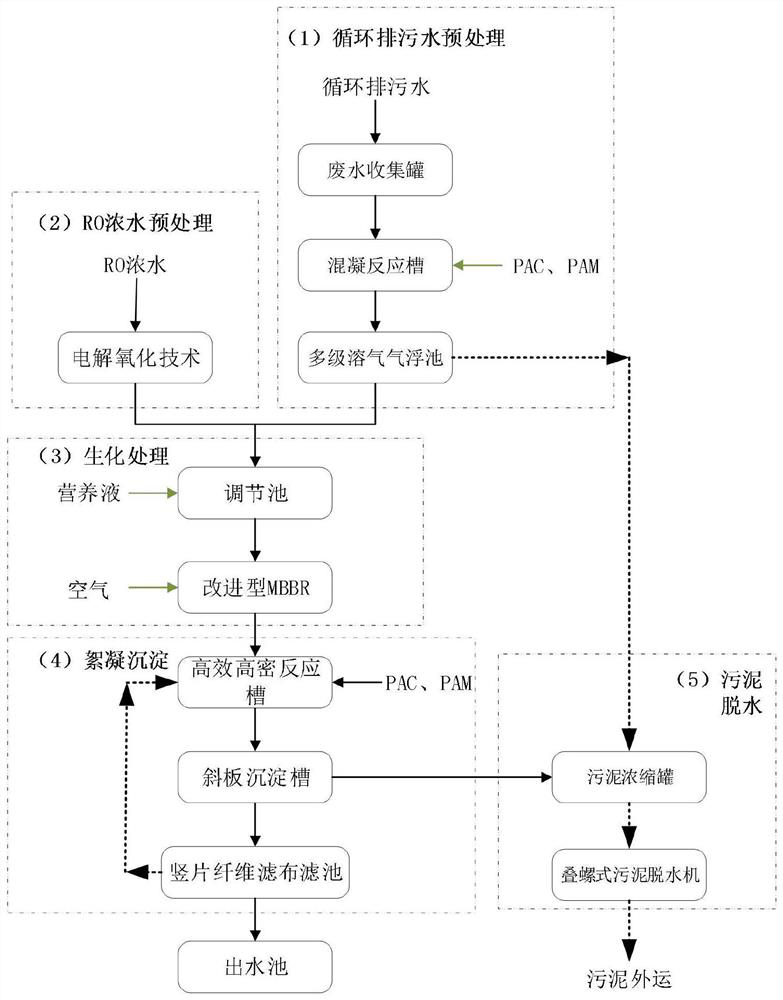

[0049] Such as figure 1 As shown, the wastewater treatment process includes the following parts in the present embodiment:

[0050] (1-1) Circulating sewage pretreatment: Circulating sewage is pumped into the wastewater collection tank, and then enters the coagulation air flotation process route. The coagulation air flotation process has the advantages of less dosage, convenient operation and management, and no It requires too much floor space; the coagulation and air flotation process is used to pretreat the circulating sewage, which can lay a good foundation for the biochemical system;

[0051] (1-2) Pretreatment of RO concentrated water: Electrocatalytic technology is used to ...

Embodiment 2

[0061] A new circulating sewage and RO concentrated water treatment station is newly built in the water plant of a chemical enterprise, with a treatment scale of 200m of circulating sewage 3 / h, RO concentrated water volume is 200m 3 / h, all types of wastewater influent COD ≤ 500mg / L, SS ≤ 300mg / L, total phosphorus ≤ 5mg / L.

[0062] Such as figure 1 As shown, the wastewater treatment process includes the following parts in the present embodiment:

[0063] (1-1) Circulating sewage pretreatment: Circulating sewage is pumped into the wastewater collection tank, and then enters the coagulation air flotation process route. The coagulation air flotation process has the advantages of less dosage, convenient operation and management, and no It requires too much floor space; the coagulation and air flotation process is used to pretreat the circulating sewage, which can lay a good foundation for the biochemical system;

[0064] (1-2) Pretreatment of RO concentrated water: Electrocata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com