Solar micro-power method and system for treating pig farm biogas slurry biological matrix

A technology of biological substrate and treatment system, which is applied in the ecological treatment of biogas slurry in pig farms in the south of the Yellow River in China, and the field of biogas slurry waste pollutant treatment system, can solve the problem of reducing wetland area, large wetland area and increasing Engineering cost and other issues, to achieve the effect of low construction cost, low engineering investment and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

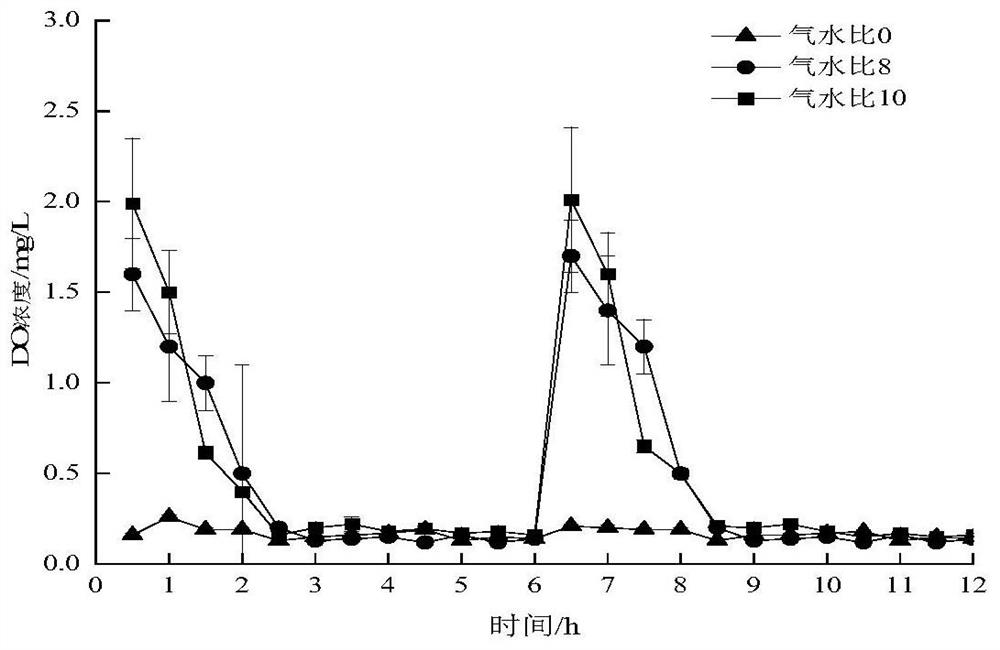

Embodiment 1

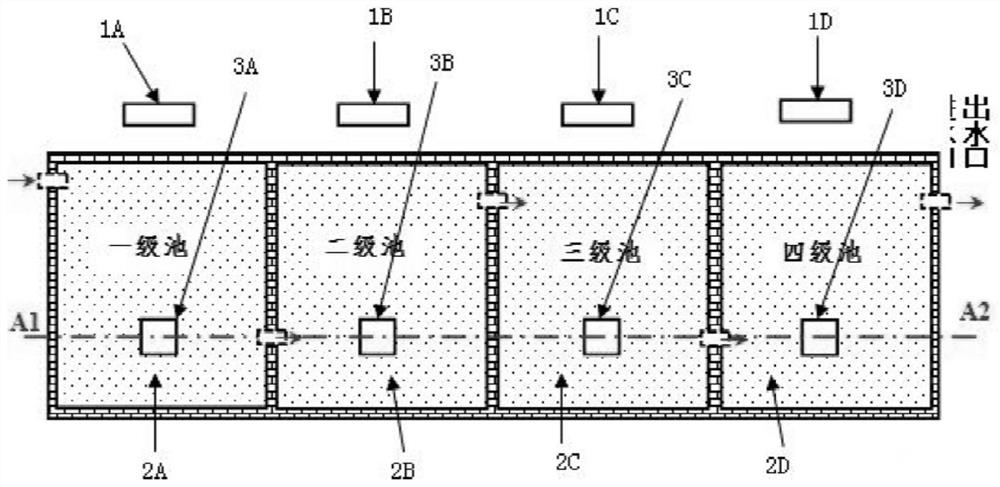

[0054] according to Figure 2A and Figure 2B It can be seen that a kind of solar energy micro-power pig farm biogas slurry biological matrix treatment method, its steps are:

[0055] A. Build a biological matrix pool: build a biological matrix pool, mainly through biological matrix materials (straw, corn stalk, wheat straw, etc.) to degrade wastewater COD and absorb nitrogen and phosphorus. The specifications of the biological matrix pool are determined according to the number of pigs in stock. The technical parameters and space layout requirements of the matrix pool mainly include:

[0056] 1) The depth of the biomatrix pool is 200 or 220 or 235 or 250cm, and the volume requirement is 0.2 or 0.3m 3 / head of pigs in stock. The biological matrix pool is divided into 3 or 4 grades on the basis of ensuring the total volume.

[0057] 2) The wall and bottom of the biomatrix pool are required to have an anti-seepage function. The wall material is a brick-concrete structure wit...

Embodiment 2

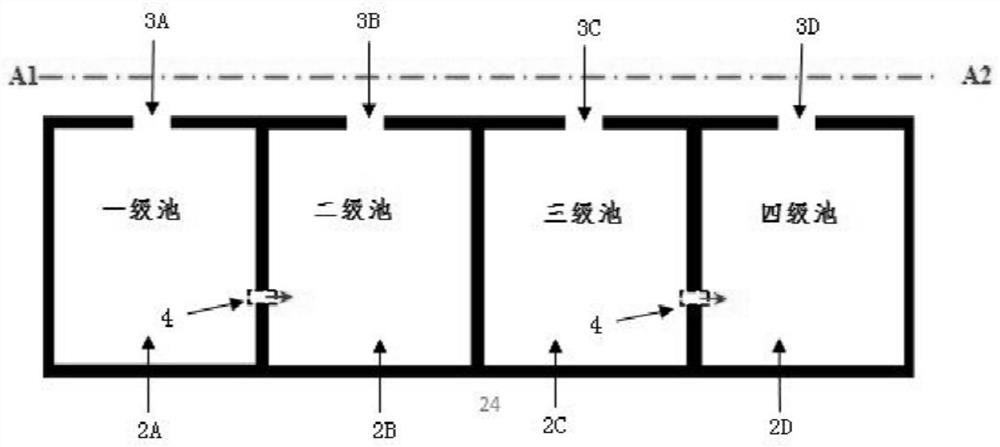

[0077] according to Figure 2A , Figure 2B , image 3 It can be seen that a treatment system utilizing a solar micro-aeration device to treat large-scale pig farm wastewater includes a No. 1 solar micro-aeration device 1A, a first-level biological matrix pool 2A, and a biological matrix material 5. The connection relationship is: two The first-level biological matrix pool 2B is connected to the first-level biological matrix pool 2A and the third-level biological matrix pool 2C respectively, the third-level biological matrix pool 2C is connected to the fourth-level biological matrix pool 2D, and the first-level biological matrix pool 2A, The secondary biomatrix pool 2B, the tertiary biomatrix pool 2C, and the quaternary biomatrix pool 2D are connected to each other by diversion holes 4 in a transversal layout. Corresponding aeration discs 14 are housed in the matrix pool 2B, the third-level biological matrix pool 2C, and the fourth-level biological matrix pool 2D. , 2C, 2D)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average removal rate | aaaaa | aaaaa |

| Average removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com