Fully-fabricated prestressed concrete frame structure anti-seismic joint

A frame structure and prestressing technology, applied in the direction of earthquake resistance, building components, building structures, etc., can solve problems such as failure of the overall structure, potential safety hazards, and damage to the connection nodes between frame beams and frame columns, so as to improve earthquake resistance and increase The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

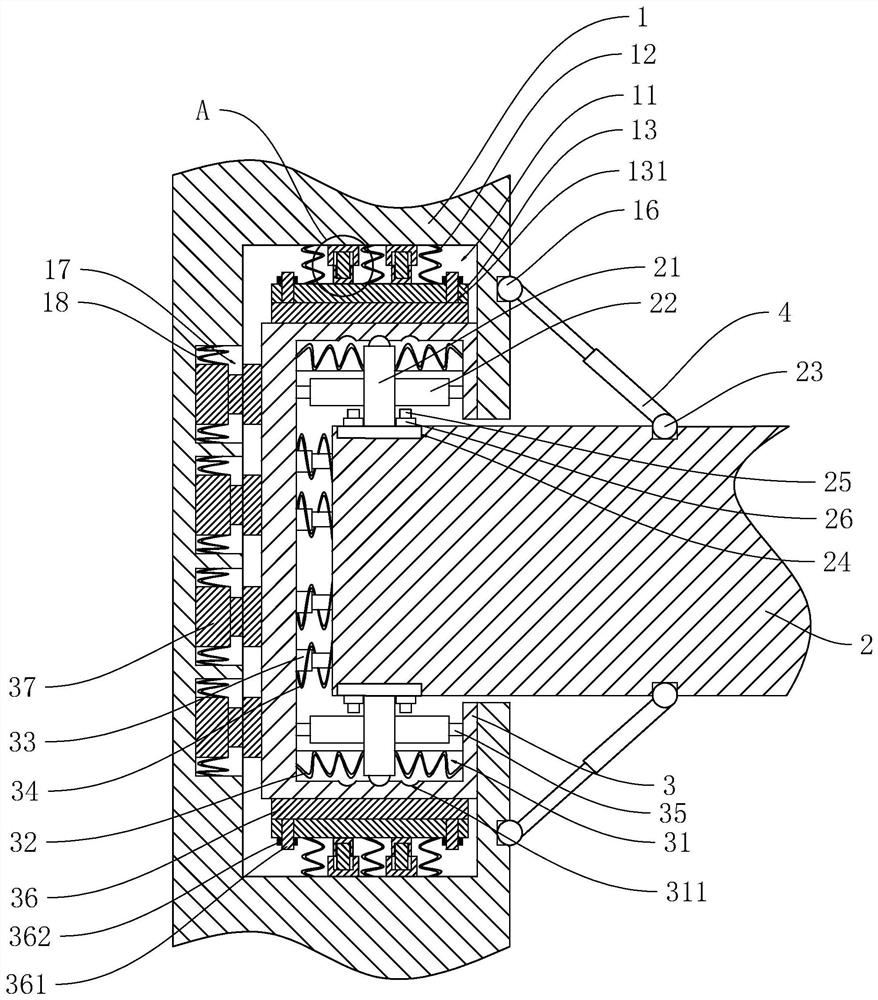

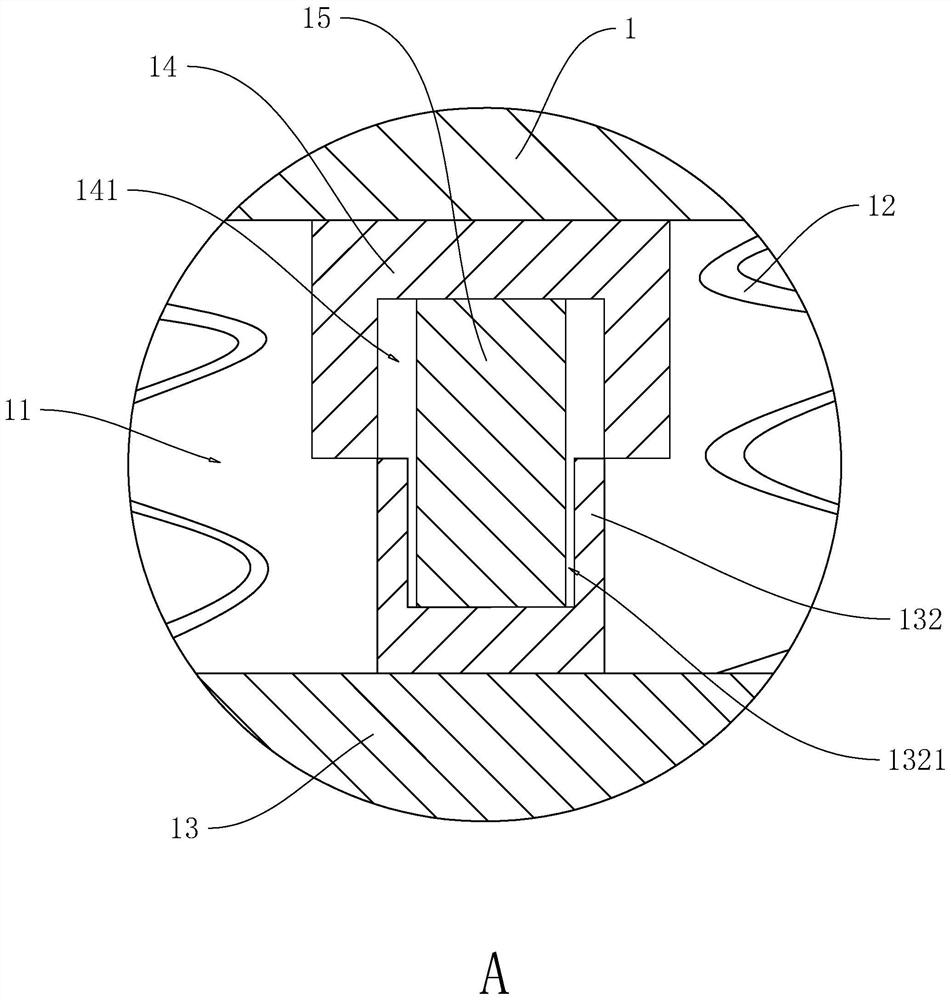

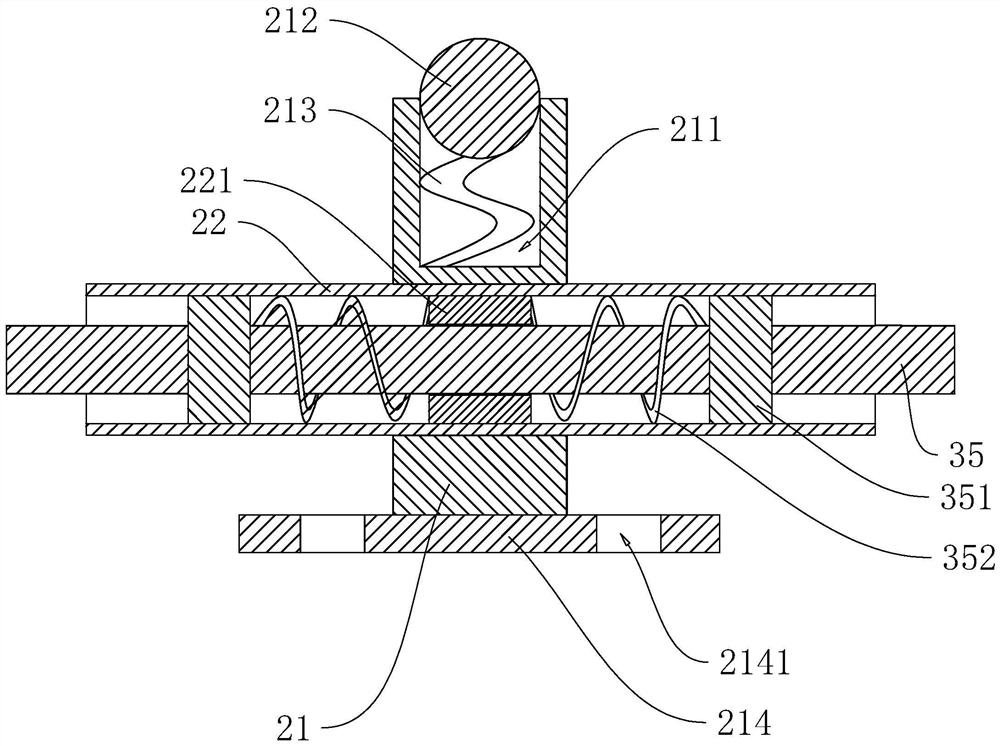

[0034] The following is attached Figure 1-3 The application is described in further detail.

[0035] The embodiment of the present application discloses a fully assembled prestressed concrete frame structure anti-seismic node. refer to figure 1 , the fully assembled prestressed concrete frame structure seismic node includes a frame column 1, and a placement cavity 11 is opened on the frame column 1, and a frame beam 2 is installed in the placement cavity 11, and the frame column 1 and the frame beam 2 is provided with an anti-seismic device, the anti-seismic device can not only make the frame column 1 and the frame beam 2 firmly assembled together, but also facilitate the effective buffering and anti-seismic effect on the frame beam 2, so that when a slight earthquake occurs, it can The situation of damage at the connection node between the frame beam 2 and the frame column 1 is reduced, and then the energy of the earthquake is effectively dissipated, so as to improve the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com