Steel wire rope double-loop magnetic flaw detection sensor

A magnetic flaw detection and sensor technology, applied in the field of sensors, can solve the problems of wire rope uniformity deviation, influence detection, false alarm, etc., and achieve the effects of stable and reliable work, improved accuracy, and wide practical range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

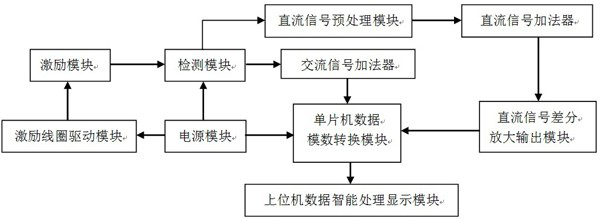

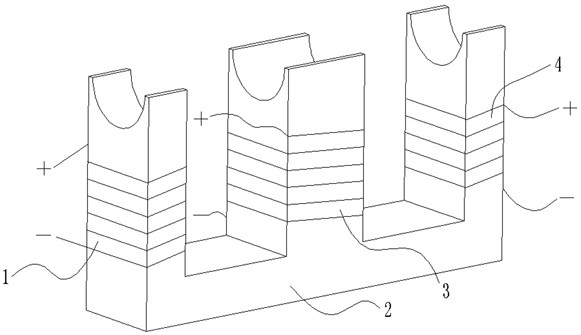

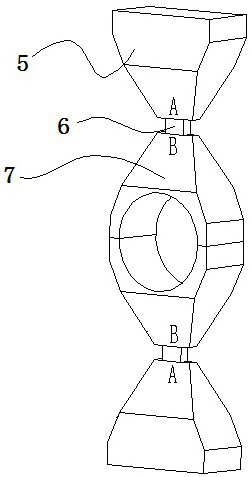

[0023] The present invention is illustrated below by way of examples. Such as figure 1 As shown, the present invention provides a steel wire rope double-loop magnetic flaw detection sensor, which is composed of a sensor detection module, a sensor control module, and an intelligent processing module of a sensor host computer; wherein the sensor detection module is composed of a magnetic field generation module, a magnetic field detection module Composed; the control module of the sensor includes a DC signal detection preprocessing module, an AC signal adder module, a DC signal adder, a DC signal differential amplifier circuit, a single-chip analog-to-digital conversion module, and a power module; wherein the control module of the sensor implements two Set of processing circuits, when the excitation source is a DC power supply, the signal generated by the detection module is transmitted to the DC signal detection preprocessing module, and then enters the DC signal adder, DC sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com