Heat-setting metal spraying frame clamp for automobile electric drive capacitor core

An electric drive and capacitor technology, applied in capacitors, capacitor manufacturing, laminated capacitors, etc., can solve problems such as poor overload current carrying capacity, lower flat core withstand voltage, and flat core end faces are prone to whitening, etc., to achieve large overload current, improve withstand voltage, and avoid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

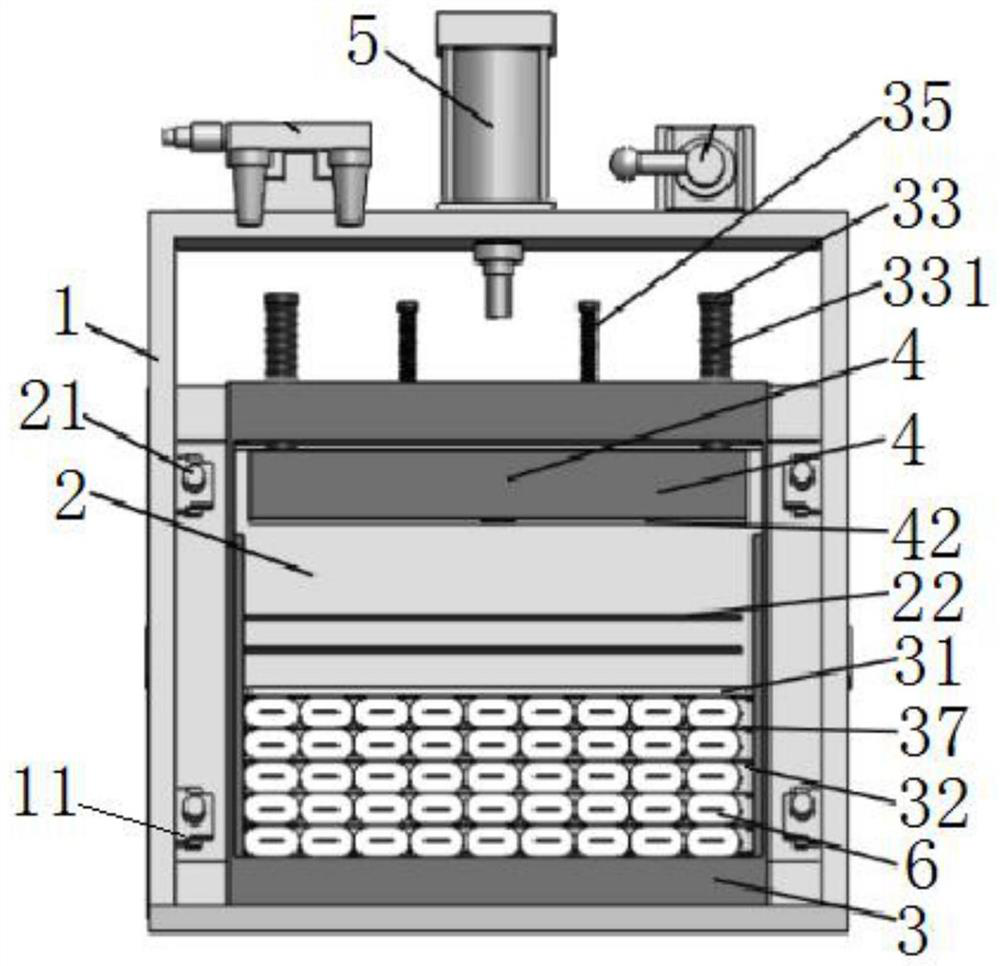

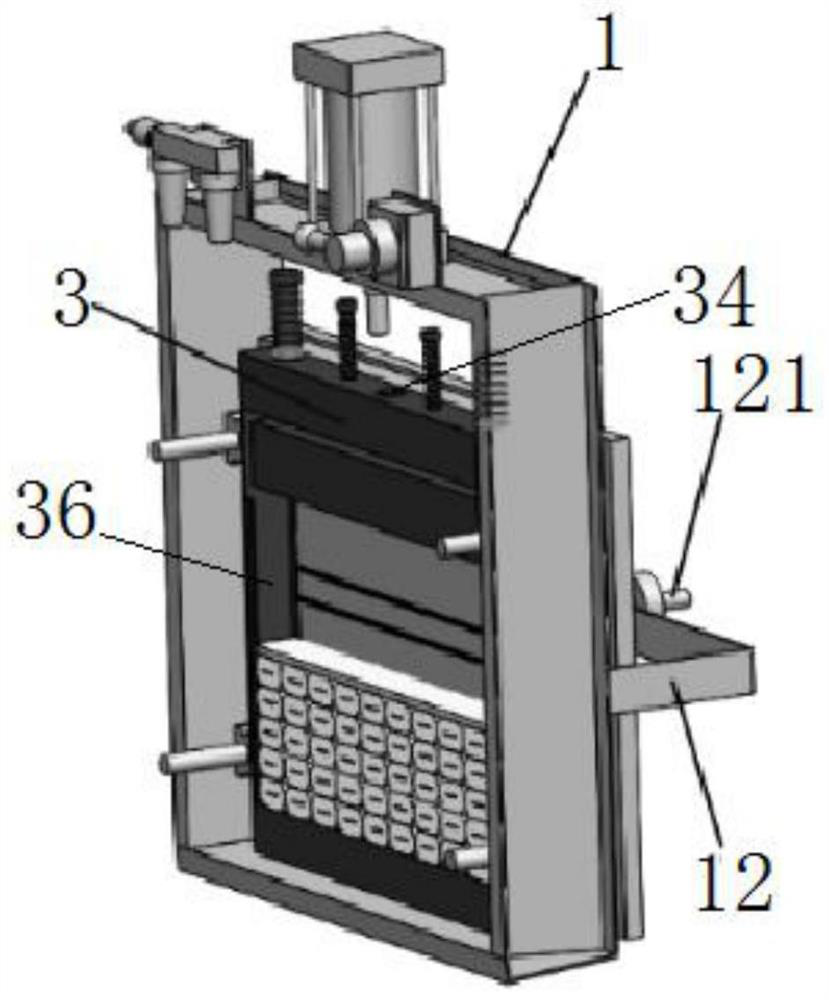

[0021] Embodiment 1, referring to the accompanying drawings, a heat-setting gold-sprayed frame fixture for an electric drive capacitor core of an automobile, comprising a frame 1, a baffle plate 2, a frame 3, a pressing assembly 4 and a cylinder 5; the frame 1 is a frame body structure; the frame 3 is arranged inside the frame 1, and its lower end abuts against the inner bottom end of the frame 1; the baffle plate 2 is arranged at the rear end of the frame 1; the frame 3 The rear end leans against the baffle 2;

[0022] The frame 3 is provided with a pressing plate 31; the pressing plate 31 is arranged horizontally and slid vertically; a cavity 32 for placing the flat core 6 is provided between the pressing plate 31 and the bottom end of the frame 3; A multi-layer flat core 6 is placed in the cavity 32;

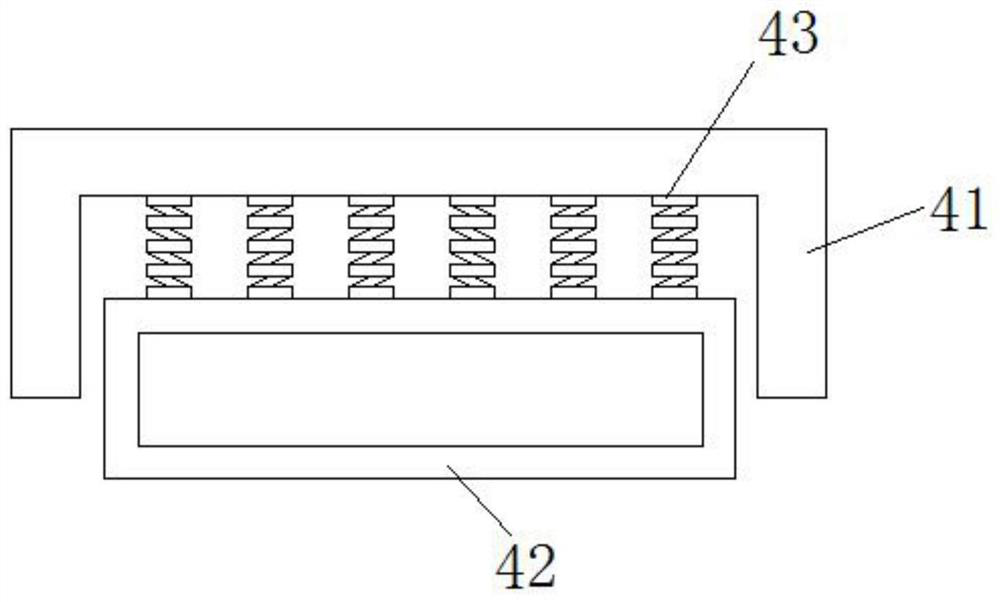

[0023] The top of the frame 3 is vertically provided with a guide column 33; the guide column 33 is arranged to move up and down along the frame 3; the pressing assembly 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com