Novel P-type crystalline silicon cell back contact passivation preparation process

A technology of crystalline silicon cell and preparation process, applied in sustainable manufacturing/processing, circuit, photovoltaic power generation, etc., can solve the problems of increasing fill factor loss, increasing metal contact area recombination, silicon material damage, etc., to improve conversion efficiency , The effect of reducing compound current and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

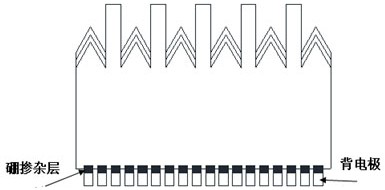

[0009] The present invention proposes a new P-type crystalline silicon battery back contact passivation preparation process, which consists of figure 1 As shown, by preparing a boron re-doped layer on the back electrode, not only the contact resistance of the metal area is reduced, but also the back metal contact area is passivated. The specific technical scheme is as follows:

[0010] 1. To clean the cashmere, adopt the prior art.

[0011] 2. Diffusion junction, using the existing technology.

[0012] 3. Removing PSG and back etching, using the existing technology.

[0013] 4. High temperature oxidation, using existing technology.

[0014] 5. Laser doping, using existing technology.

[0015] 6. The anti-reflection film on the front adopts the existing technology.

[0016] 7. Passivation and anti-reflection film on the back surface, using existing technology to prepare silicon nitride film on the back surface.

[0017] 8. The laser groove on the back adopts the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com