Preparation method of micro LED chip

A chip and buffer layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of sidewall etching damage, reduce chip brightness, etc., and achieve the effect of reducing dislocation density, improving brightness, and reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as Figure 1 to Figure 4 As shown, this embodiment provides a method for preparing a Micro LED chip, and the method for preparing includes the following steps:

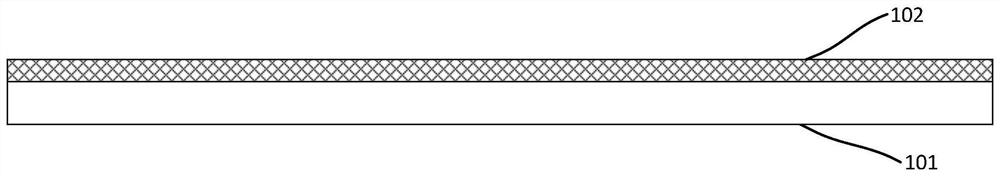

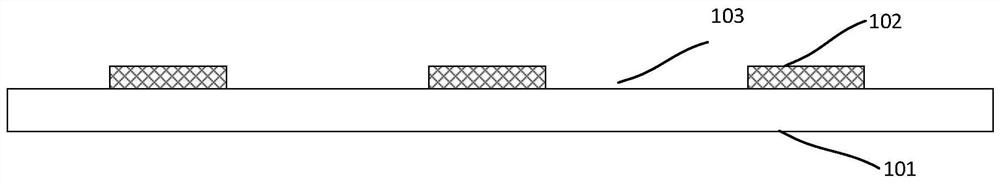

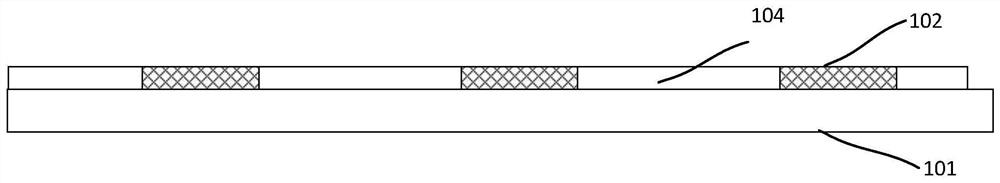

[0037] Such as Figure 1 ~ Figure 2 As shown, step 1) is first performed, a substrate 101 is provided, and a patterned buffer layer 102 is formed on the substrate 101. There is a gap 103 between adjacent buffer layers 102, and the gap 103 is covered with a mask layer. 104. However, in the prior art, the buffer layer is usually a whole.

[0038] In this embodiment, the size of the gap 103 is larger than the lateral growth size of the LED epitaxial layer in the stage of epitaxially growing the LED epitaxial layer in the subsequent step 2).

[0039] Specifically, step 1) includes the following steps:

[0040] In step 1-1), a substrate 101 is provided, and a buffer layer 102 is formed on the substrate 101 .

[0041] The substrate 101 may be a sapphire substrate or a silicon substrate, and the buffer layer ...

Embodiment 2

[0055] Such as Figure 5 As shown, this embodiment provides a method for preparing a Micro LED chip, the basic steps of which are as in Embodiment 1, wherein, the difference from Embodiment 1 is that: Step 1) also includes resetting the patterned buffer layer 102 A patterning step to improve the crystal quality of the LED epitaxial layer in step 2).

[0056] As mentioned above, the preparation method of the Micro LED chip of the present invention has the following beneficial effects:

[0057] In the present invention, during the epitaxy process of the LED epitaxial layer, no epitaxial layer is deposited on the mask layer 104, and the epitaxial layer is only deposited on the buffer layer 102, and each buffer layer 102 is a complete LED epitaxial structure, which is mutually due to The distance between the mask layers 104 makes it difficult for the LED epitaxial layers to merge laterally during the epitaxy process, thereby obtaining mutually independent LED epitaxial layers.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com