Elastic filter geotextile and preparation method thereof

A technology of anti-filtering geotextiles and composite geotextiles, applied in soil protection, infrastructure engineering, textile and other directions, can solve the problems of inelastic and self-adaptive deformation ability, low maintenance cost, poor mechanical strength, etc., to achieve a wide range of projects Application scenarios, the effect of enhancing tensile strength and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of an elastic filter geotextile provided in this embodiment comprises the following steps:

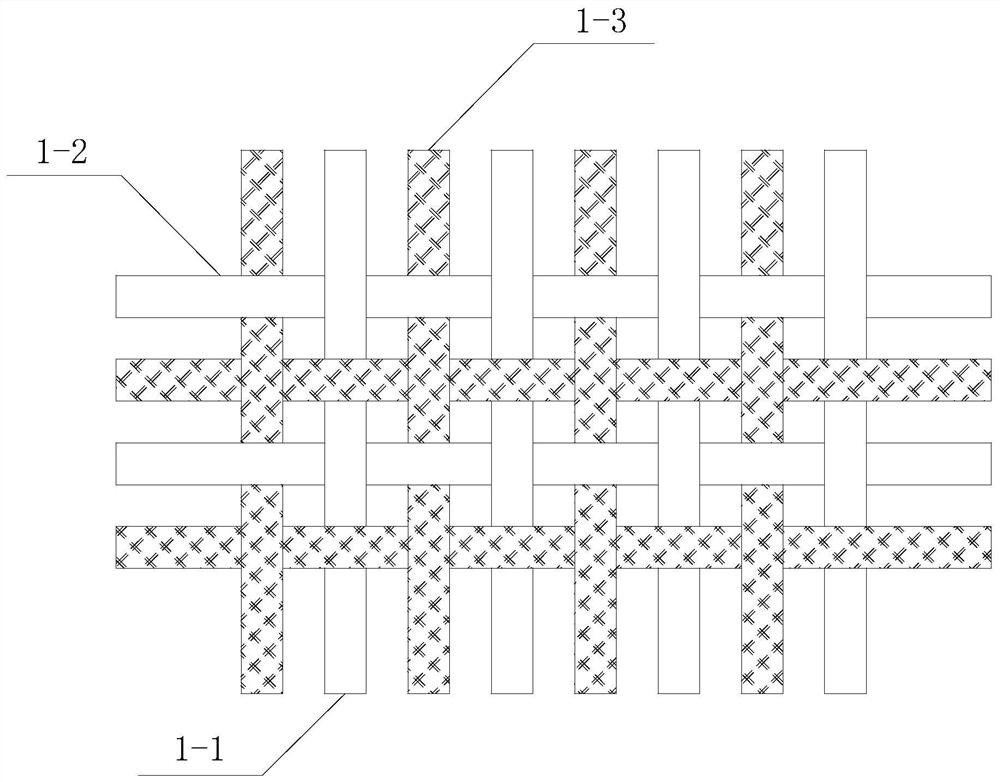

[0033] (1) Preparation of elastic fiber composite geotextile 1: using polymer (such as rubber) as raw material, the polymer is drawn into the form of yarn by raising the temperature to make warp yarn 1-1 and weft yarn 1-2; The knitting machine weaves the warp yarn 1-1 and the weft yarn 1-2 together with the elastic fiber 1-3 to make an elastic fiber composite geotextile 1;

[0034] (2) Preparation of elastic non-woven fabric 2: chemical fiber is used as raw material, wherein elastic masterbatch is added, and chemical or hot-melt bonding makes it have the functions of water permeability and sand filtering of non-woven fabric, and has elasticity;

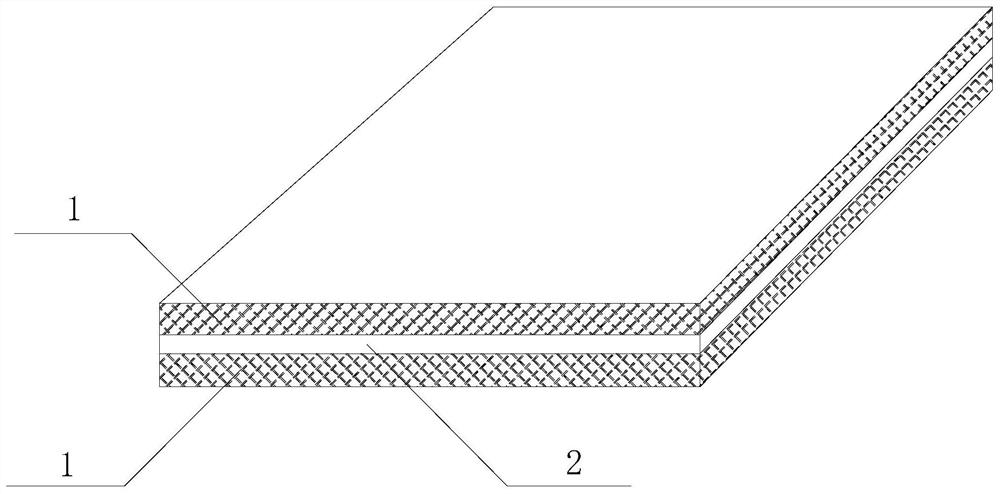

[0035] (3) The upper layer of elastic fiber composite geotextile 1, elastic non-woven fabric 2, and the lower layer of elastic fiber composite geotextile 1 are sewn together by acupuncture or stitching to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com