Auxiliary composition and its preparation method, linear low density polyethylene composition and its preparation method, and polyethylene cast packaging film

A linear low-density, composition technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. The effect of smooth film, less precipitate and low haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

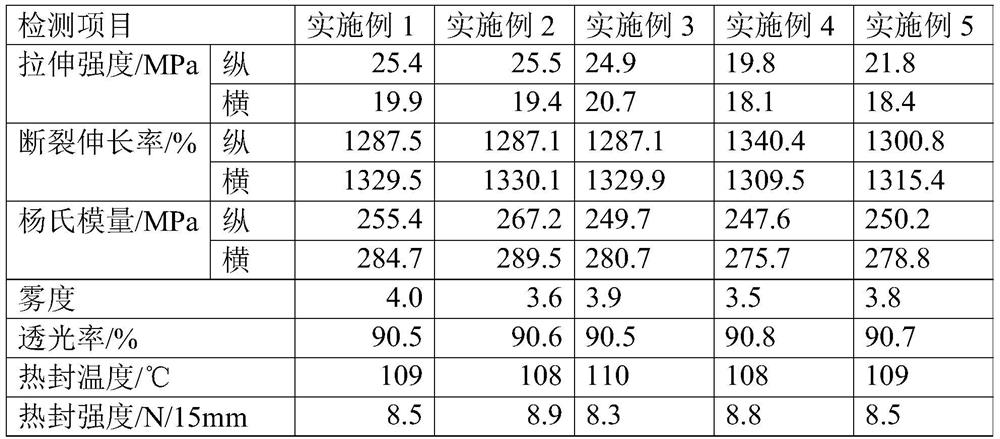

Examples

Embodiment 1

[0054] This embodiment is used to prepare polyethylene cast packaging film, and concrete steps are as follows:

[0055] (1) preparation auxiliary composition:

[0056] Based on the total weight of the additive composition, the antioxidant 1010 with a content of 18% by weight, the antioxidant 168 with a content of 18% by weight, the zinc stearate with a content of 5% by weight, and the hydrotalcite with a content of 8% by weight (DHT-4A, particle size 0.4 μm), silicon dioxide (AB905, particle size 5 μm) with a content of 48% by weight and antistatic agent 1800 with a content of 3% by weight were mixed to obtain an additive composition.

[0057] (2) Preparation of linear low density polyethylene composition:

[0058] Prepared by the Unipol gas phase process, the melt index is 4.0g / 10min and the density is 0.927g / cm at 2.16kg load and 190°C 3 linear low density polyethylene;

[0059] Based on the total weight of the linear low-density polyethylene composition, the auxiliary ag...

Embodiment 2

[0067] This embodiment is used to prepare polyethylene cast packaging film, and concrete steps are as follows:

[0068] (1) preparation auxiliary composition:

[0069] Based on the total weight of the additive composition, the antioxidant 1010 with a content of 15% by weight, the antioxidant 168 with a content of 20% by weight, the zinc stearate with a content of 5% by weight, and the hydrotalcite with a content of 10% by weight (particle size: 0.7 μm), silicon dioxide (particle size: 8 μm) with a content of 48% by weight and antistatic agent 1800 with a content of 2% by weight were mixed to obtain an additive composition.

[0070] (2) Preparation of linear low density polyethylene composition:

[0071] Prepared by the Unipol gas phase process, the melt index is 3.5g / 10min and the density is 0.925g / cm at 2.16kg load and 190°C 3 linear low density polyethylene;

[0072] Based on the total weight of the linear low density polyethylene composition, the auxiliary agent composit...

Embodiment 3

[0080] This embodiment is used to prepare polyethylene cast packaging film, and concrete steps are as follows:

[0081] (1) preparation auxiliary composition:

[0082]Based on the total weight of the additive composition, the antioxidant 1010 with a content of 20% by weight, the antioxidant 168 with a content of 15% by weight, the zinc stearate with a content of 5% by weight, and the hydrotalcite with a content of 15% by weight (particle size: 0.5 μm), silicon dioxide (particle size: 8 μm) with a content of 43% by weight and antistatic agent 1800 with a content of 2% by weight were mixed to obtain an additive composition.

[0083] (2) Preparation of linear low density polyethylene composition:

[0084] Prepared by the Unipol gas phase process, the melt index is 3.0g / ml and the density is 0.925g / cm at 2.16kg load and 190°C 3 linear low density polyethylene;

[0085] Based on the total weight of the linear low density polyethylene composition, the auxiliary agent composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com