Production formula and process of modified polypropylene special for melt-blown cloth

A production process and production formula technology, applied in the direction of single-component polyolefin rayon, non-woven fabrics, fiber chemical characteristics, etc., can solve the problems of high production technology requirements and small investment, so as to avoid uncontrollable safety hazards, The effect of small ash content and small fluctuation range of melting index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

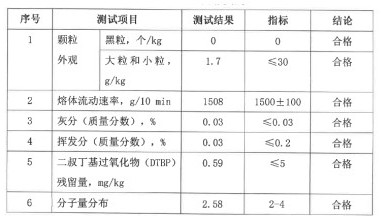

[0012] A special modified polypropylene production formula for melt-blown cloth, characterized in that it consists of a mixture of 99.4% PP, 0.4% di-tert-butyl peroxide (DTBP) and 0.2% antioxidant, the 0.2% Antioxidant is made by mixing Antioxidant 168 and Antioxidant 1010 at a ratio of 2:1.

[0013] A production process for a special modified polypropylene production formula for melt-blown cloth, characterized in that it comprises the following steps: 1) uniformly mixing the PP raw material and the antioxidant mixture in a 200L mixing pot for 3 minutes, And in this process, the step of uniform and uninterrupted stirring is carried out; 2) the corresponding materials are respectively put into the silo of the loss-in-weight feeding system, and the corresponding ratio is set through the control system; 3) the speed of the extruder is set to Set at 450r / min, the temperature of each functional zone of the extruder host is between 190°C and 240°C, and the step of feeding the powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com