Preparation method and application method of silicon dioxide cluster-based novel settling agent

A technology of silicon dioxide and sedimentation agent, applied in the directions of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problems of beneficial water biological hazards, high residual metal ion content, destroying ecological balance, etc., and inhibit the growth of cyanobacteria. , Reduce the residual amount, the effect of adjustable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

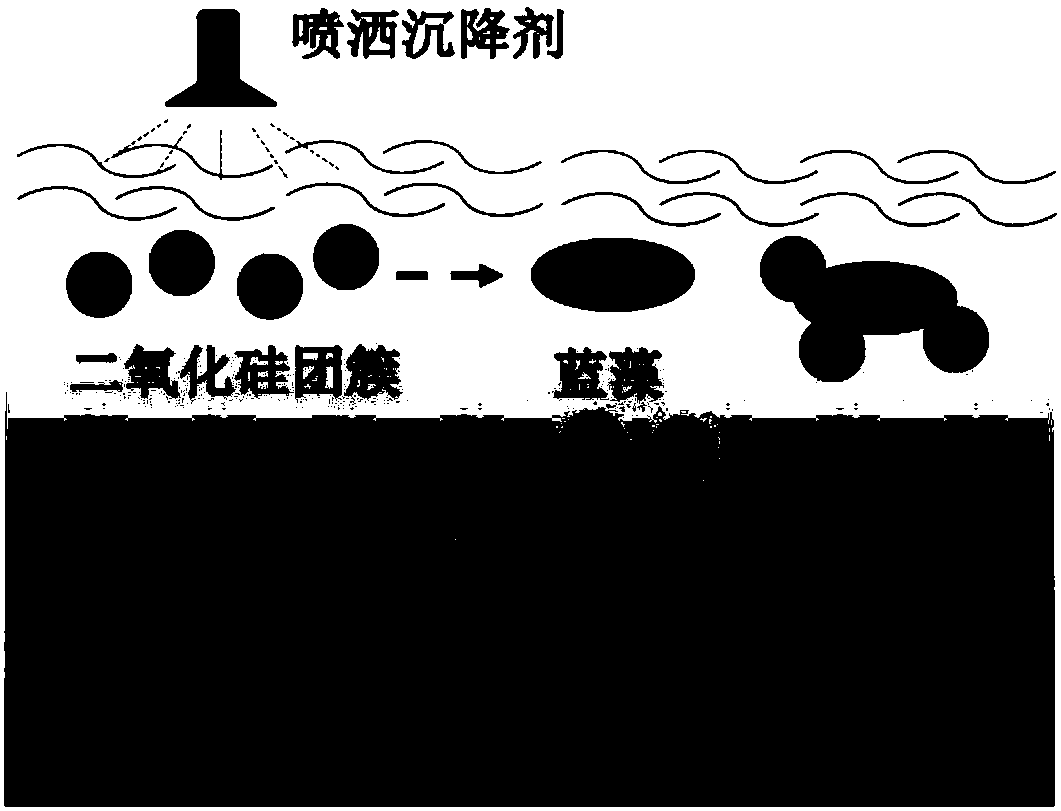

[0035] A method for preparing a new type of sedimentation agent based on silica clusters, using silica clusters as the main body of the sedimentation agent, utilizing the strong interaction between silica clusters and metal ions, and combining metal salt solution with The aqueous solution of the silica cluster is fully mixed to obtain a uniform solution of the metal salt-modified settling agent, which is a new type of settling agent;

[0036] The silicon dioxide clusters use an aqueous solution of silicon dioxide particles;

[0037] The density or size of the silica clusters can be adjusted, and the degree of polymerization can be adjusted by standing and aging at a certain temperature, thereby adjusting the density or size.

[0038] Specific steps are as follows:

[0039] (1) Preparation of aqueous solution of silica particles:

[0040] Add 50g elemental silicon powder into 100mL water, heat to 98°C, stir for 30min, and dissolve 0.4g sodium hydroxide in 200mL water, slowly ...

Embodiment 2

[0046] A method for preparing a new type of sedimentation agent based on silica clusters, using silica clusters as the main body of the sedimentation agent, utilizing the strong interaction between silica clusters and metal ions, and combining metal salt solution with The aqueous solution of the silica cluster is fully mixed to obtain a uniform solution of the metal salt-modified settling agent, which is a new type of settling agent;

[0047] The silicon dioxide clusters use an aqueous solution of silicon dioxide particles;

[0048] The density of the silica cluster is adjustable, and its degree of polymerization can be adjusted by standing and aging at a certain temperature, thereby adjusting its density.

[0049] Specific steps are as follows:

[0050] (1) Preparation of aqueous solution of silica particles:

[0051] Add 50g elemental silicon powder into 100mL water, heat to 98°C, stir for 30min, and dissolve 0.4g sodium hydroxide in 200mL water, slowly add the sodium hydr...

Embodiment 3

[0057] A method for preparing a new type of sedimentation agent based on silica clusters, using silica clusters as the main body of the sedimentation agent, utilizing the strong interaction between silica clusters and metal ions, and combining metal salt solution with The aqueous solution of the silica cluster is fully mixed to obtain a uniform solution of the metal salt-modified settling agent, which is a new type of settling agent;

[0058] The silicon dioxide clusters use an aqueous solution of silicon dioxide particles;

[0059] The density of the silica cluster is adjustable, and its degree of polymerization can be adjusted by standing and aging at a certain temperature, thereby adjusting its density.

[0060] Specific steps are as follows:

[0061] (1) Preparation of aqueous solution of silica particles:

[0062] Add 50g elemental silicon powder into 100mL water, heat to 98°C, stir for 30min, and dissolve 0.4g sodium hydroxide in 200mL water, slowly add the sodium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com