Preparation method of liquid amine type antioxidant

A kind of amine antioxidant, liquid technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

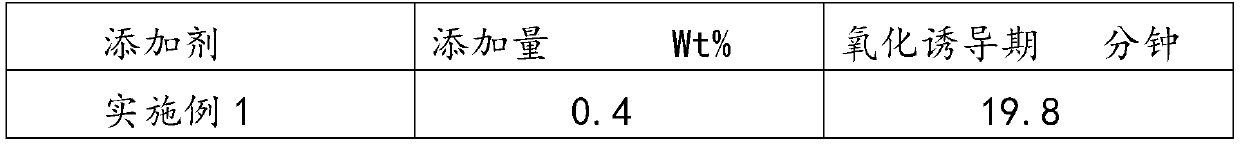

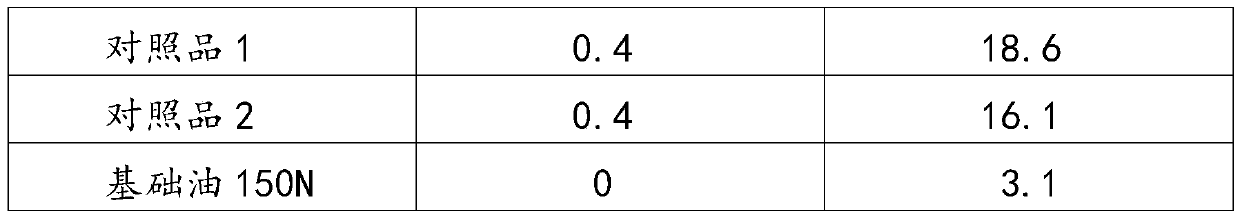

Examples

Embodiment 1

[0020] The present embodiment provides a kind of preparation method of liquid amine antioxidant RF5057, comprises the following steps:

[0021] (1) Add 200g activated clay, 2g p-toluenesulfonic acid and 5g activated alumina to compound in the mixing device, and start the mixing device for half an hour to obtain a uniformly mixed activated clay composite catalyst, which is ready for use.

[0022] Add 130g diphenylamine, 30g activated clay composite catalyst, 90ppm polymerization inhibitor hydroquinone in the stainless steel reaction kettle, feed nitrogen into the reaction kettle, fully replace the air in the kettle, and start heating. At the same time, the vacuum system is turned on, and the vacuum degree in the kettle is controlled at 0.08MPa~0.095MPa. When the temperature reaches about 70°C, the stirring is started at a stirring rate of 300 rpm, and the moisture in the reaction system is removed under vacuum conditions. Gradually raise the temperature to 100°C for half an ho...

Embodiment 2

[0026] The present embodiment provides a kind of preparation method of liquid amine antioxidant RF5057, comprises the following steps:

[0027] (1) Add 200g of activated clay, 1g of p-toluenesulfonic acid and 3g of activated alumina in the mixing device to compound, and start the mixing device for half an hour to obtain a uniformly mixed activated clay composite catalyst, which is ready for use.

[0028] Add 130g diphenylamine, 40g activated clay composite catalyst, 90ppm polymerization inhibitor hydroquinone in the stainless steel reaction kettle, feed nitrogen into the reaction kettle, fully replace the air in the kettle, and start heating. At the same time, the vacuum system is turned on, and the vacuum degree in the kettle is controlled at 0.08MPa~0.095MPa. When the temperature reaches about 70°C, the stirring is started at a stirring rate of 300 rpm, and the moisture in the reaction system is removed under vacuum conditions. Gradually raise the temperature to 100°C for h...

Embodiment 3

[0032] The present embodiment provides a kind of preparation method of liquid amine antioxidant RF5057, comprises the following steps:

[0033] (1) Add 200g of activated clay, 3g of p-toluenesulfonic acid and 1g of activated alumina to the mixing device for compounding, and start the mixing device for half an hour to obtain a uniformly mixed activated clay composite catalyst, which is ready for use.

[0034] Add 130g diphenylamine, 25g activated clay composite catalyst, 75ppm polymerization inhibitor 2,6-dinitro-p-cresol in the stainless steel reaction kettle, feed nitrogen into the reaction kettle, fully replace the air in the kettle, and start heating. At the same time, the vacuum system is turned on, and the vacuum degree in the kettle is controlled at 0.08MPa~0.095MPa. When the temperature reaches about 70°C, the stirring is started, and the stirring rate is 300 rpm, and the moisture in the reaction system is removed under vacuum conditions. Gradually raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com