Manufacturing method of high-acid-base-resistance non-woven material for wringing roller

A technology of non-woven materials and manufacturing methods, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor acid and alkali resistance, low strength, etc., to improve product grades, reduce production costs, improve squeezing performance and use effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

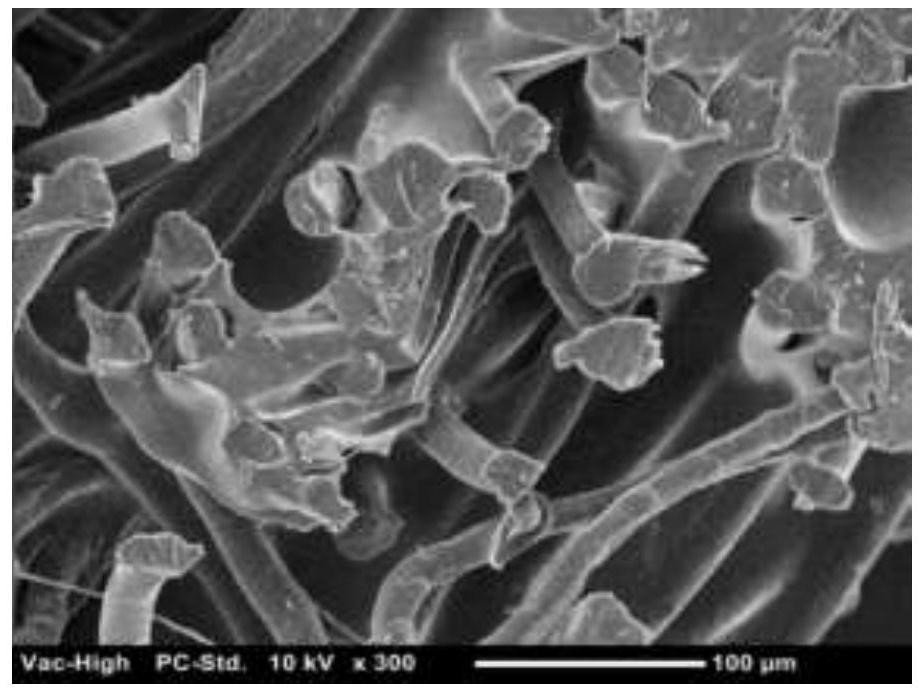

Image

Examples

Embodiment 1

[0044] A kind of manufacturing method of the highly acid-alkali-resistant nonwoven material of the present invention is used for squeezing dry roll, specifically implements according to the following steps:

[0045] Step 1, take the following raw materials respectively according to the mass percentage:

[0046] 80% high-strength polypropylene fiber, 20% ultra-high molecular weight polyethylene fiber, the sum of the above raw materials is 100%;

[0047] Among them, the high-strength polypropylene fiber has a linear density of 2.5dtex and a length of 65mm; the ultra-high molecular weight polyethylene fiber has a linear density of 2dtex and a length of 51mm;

[0048] Step 2, mixing high-strength polypropylene fibers and ultra-high molecular weight polyethylene fibers to form mixed fibers; using an opener to sequentially open and mix the mixed fibers to obtain pretreated mixed fibers;

[0049] Step 3, using a carding machine to card the pretreated mixed fibers, and then dry formi...

Embodiment 2

[0056] A kind of manufacturing method of the highly acid-alkali-resistant nonwoven material of the present invention is used for squeezing dry roll, specifically implements according to the following steps:

[0057] Step 1, take the following raw materials respectively according to the mass percentage:

[0058] 90% high-strength polypropylene fiber, 10% ultra-high molecular weight polyethylene fiber, the sum of the above raw materials is 100%;

[0059] Among them, the high-strength polypropylene fiber has a linear density of 3dtex and a length of 51mm; the ultra-high molecular weight polyethylene fiber has a linear density of 1.5dtex and a length of 51mm;

[0060] Step 2, mixing high-strength polypropylene fibers and ultra-high molecular weight polyethylene fibers to form mixed fibers; using an opener to sequentially open and mix the mixed fibers to obtain pretreated mixed fibers;

[0061] Step 3, using a carding machine to card the pretreated mixed fibers, and then dry formi...

Embodiment 3

[0068] A kind of manufacturing method of the highly acid-alkali-resistant nonwoven material of the present invention is used for squeezing dry roll, specifically implements according to the following steps:

[0069] Step 1, take the following raw materials respectively according to the mass percentage:

[0070] 75% high-strength polypropylene fiber, 25% ultra-high molecular weight polyethylene fiber, the sum of the above raw materials is 100%;

[0071] Among them, the high-strength polypropylene fiber has a linear density of 2dtex and a length of 70mm; the ultra-high molecular weight polyethylene fiber has a linear density of 2dtex and a length of 65mm;

[0072] Step 2, mixing high-strength polypropylene fibers and ultra-high molecular weight polyethylene fibers to form mixed fibers; using an opener to sequentially open and mix the mixed fibers to obtain pretreated mixed fibers;

[0073] Step 3, using a carding machine to card the pretreated mixed fibers, and then dry forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com