Drying device for tea processing and application method thereof

A drying device and technology for tea leaves, which are applied in the directions of tea drying, drying gas arrangement, drying machine for static materials, etc., can solve problems such as poor drying uniformity of tea leaves, and achieve the effect of facilitating processing, improving support effect, and avoiding loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

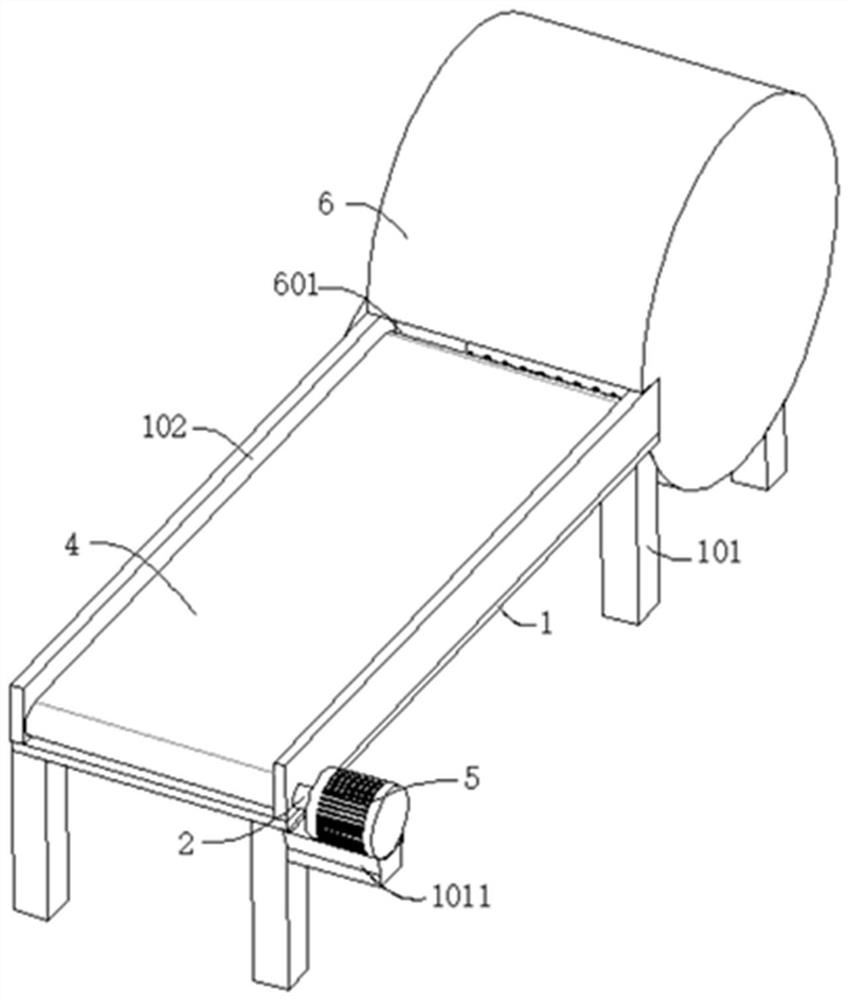

[0034] refer to Figure 1-3 , a drying device for tea processing, comprising a workbench 1, the bottom of the workbench 1 is connected with a support column 101, the top of the workbench 1 is connected to the outer walls on both sides of the vertical plate 102, and the two vertical plates 102 are connected There are a first transmission roller 2 and a second transmission roller 3, a transmission belt 4 is connected between the first transmission roller 2 and the second transmission roller 3, a support base 1011 is connected to the outer wall of the support column 101, and a motor 5 is connected to the outer wall of the support base 1011 , the output end of the motor 5 passes through the vertical plate 102 and is connected with the first transmission roller 2, the outer wall of the workbench 1 is connected with a drying box 6, and the outer walls of the drying box 6 are respectively provided with a material inlet 601 and a material outlet 602. The material opening 601 is connec...

Embodiment 2

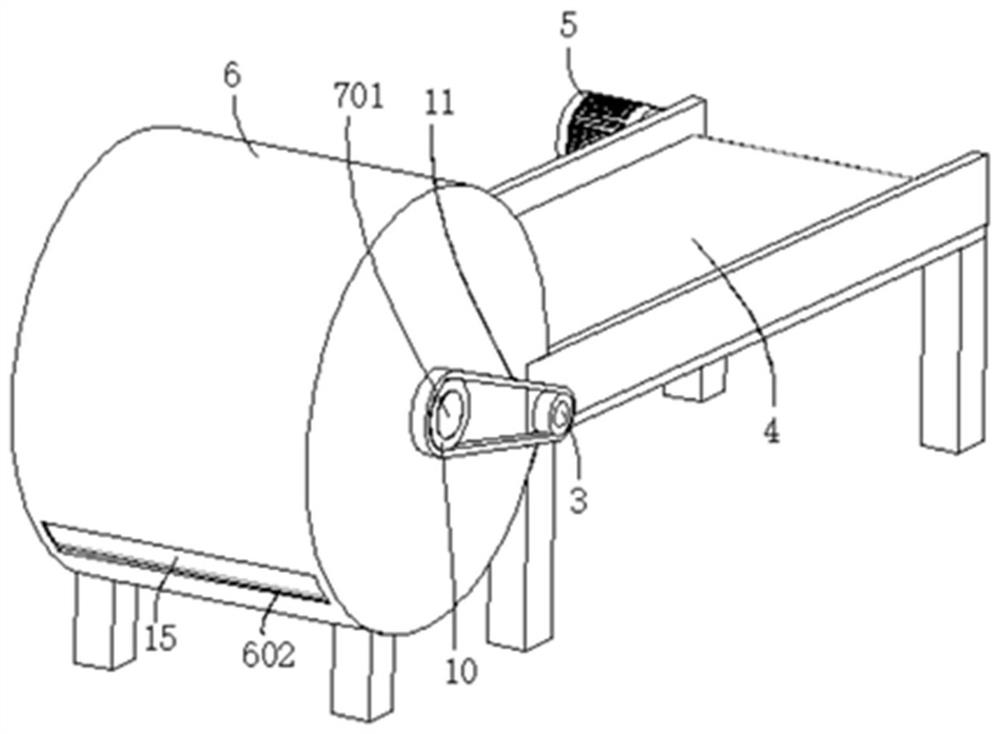

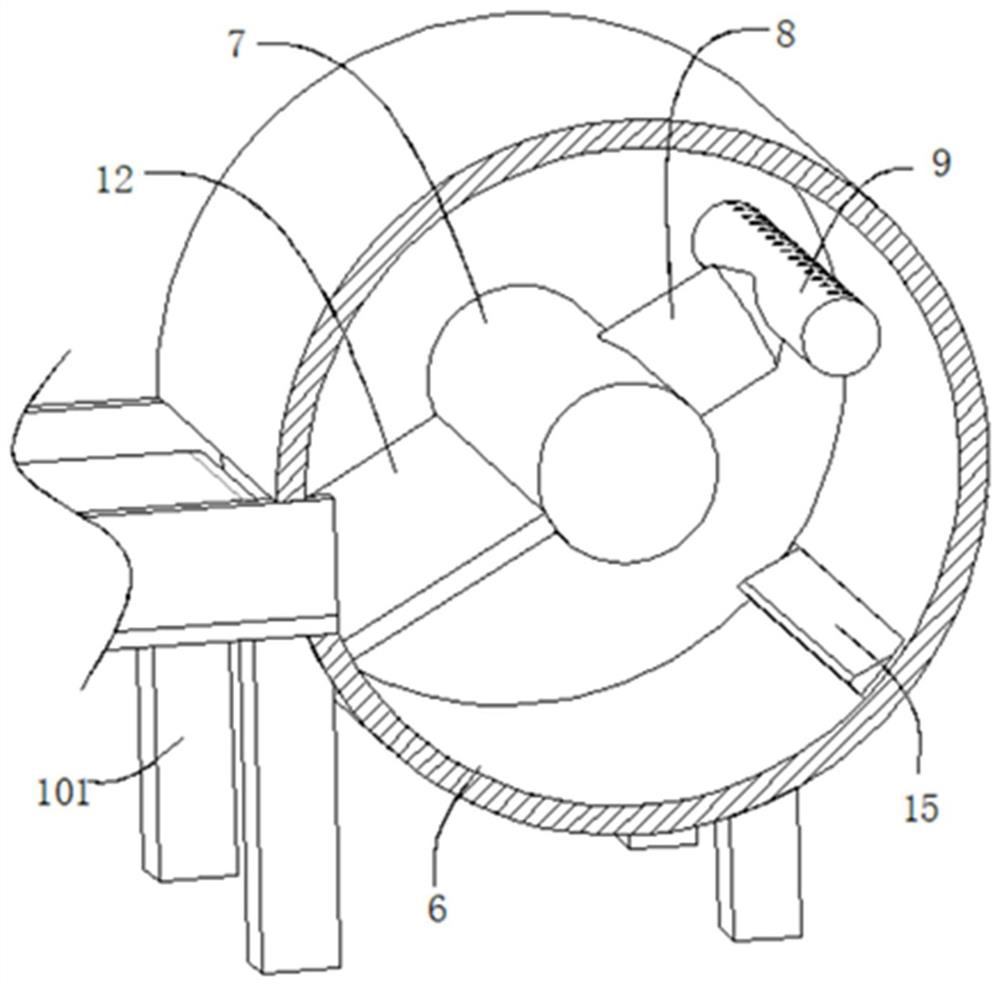

[0038] refer to Figure 1-5 , a drying device for tea processing, which is basically the same as in Example 1, and furthermore, the inner wall of the hot air pipe 7 is connected with a hot air cylinder 701, and the hot air cylinder 701 is rotatably connected in the drying box 6 through a first bearing. 701 is provided with a cavity 7011, the inner wall of the cavity 7011 is connected with a heating pipe 7012, and the inner wall of the cavity 7011 is dug with a cooling hole 7013. A bevel gear 702.

[0039] A matching synchronous pulley 10 is connected to the outer wall of the hot air cylinder 701 and the second drive roller 3 , and a synchronous belt 11 is connected between the two synchronous pulleys 10 .

[0040] The inner wall of the heat pipe 8 is connected with a fixed plate 801, and the fixed plate 801 is rotatably connected with a rotating rod 802 through a second bearing. The top of the rotating rod 802 is connected with a second bevel gear 803 that meshes with the fir...

Embodiment 3

[0044] refer to Figure 1-7 , a drying device for tea processing, which is basically the same as in Example 1, and furthermore, the outer wall of the hot gas pipe 7 away from the heat pipe 8 is connected with a scraper 12, and the scraper 12 is movable with the inner wall of the drying box 6 offset; the scraper 12 is used to scrape the dried tea leaves, so that the dried tea leaves are directly discharged from the discharge port 602, which is conducive to improving the work efficiency of tea drying, and avoids that the dried tea leaves are not discharged from the drying box 6 in time. Covering the fresh tea leaves to be dried affects the drying quality of the tea leaves.

[0045] A rotating shaft 13 is connected between the cover plate 15 and the inner wall of the discharge port 602, the cover plate 15 is connected in the discharge port 602 through the rotation of the rotating shaft 13, and the outer wall of the rotating shaft 13 is sleeved with a torsion spring 131; it is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com