Vacuum pumping bottle cap

A vacuum pumping and bottle cap technology, which is applied in the field of sealed bottles and cans, can solve the problems of prolonged pumping time, air entry, and inconvenient pumping, and achieve the effects of ensuring sealing effect, high pumping efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

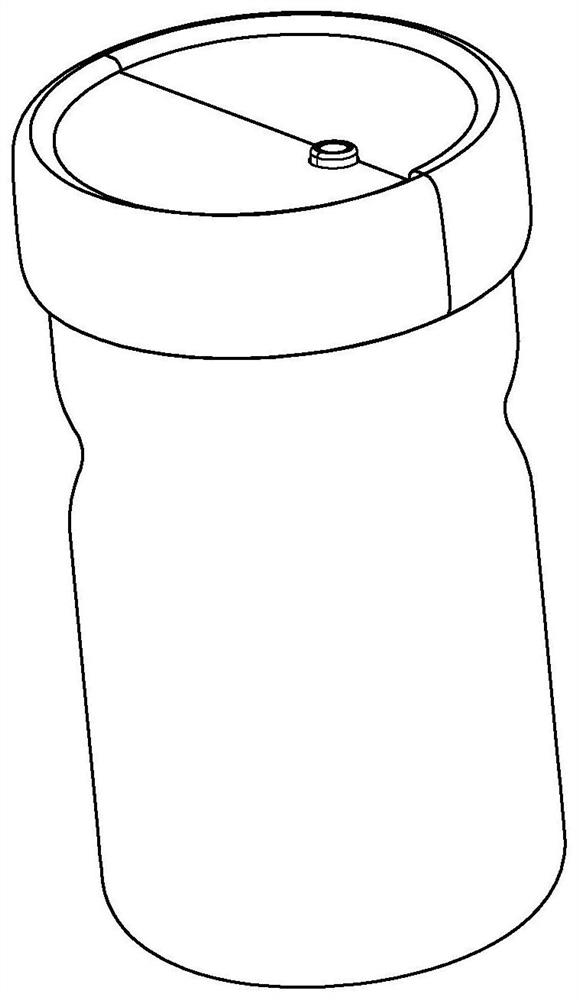

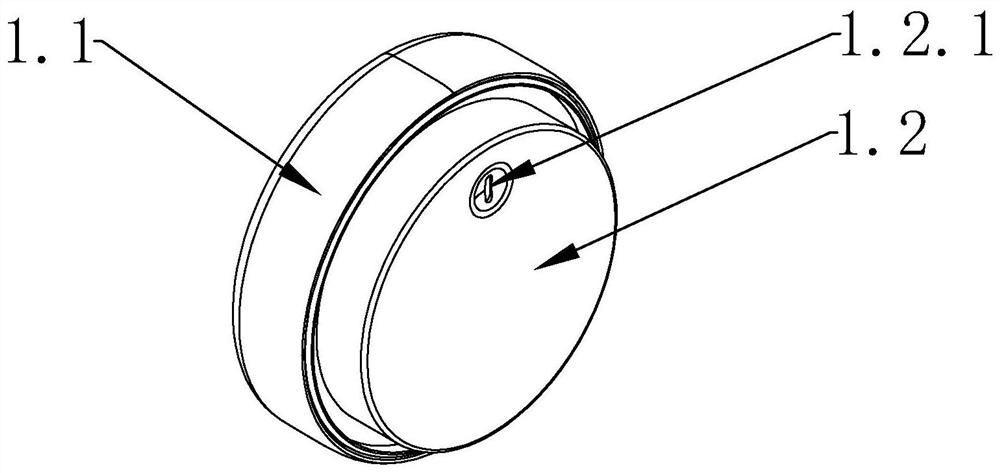

[0042] Such as Figure 1 to Figure 3 As shown, a vacuum suction bottle cap is shown, including a first cover body 1.1, a second cover body 1.2 distributed up and down and slidably connected, and an accommodating space formed by the first cover body 1.1 and the second cover body 1.2 , the accommodating space is provided with a vacuum pumping valve assembly and a pumping tool 4 communicating with the space to be pumped.

[0043] Specifically, the detachable connection between the first cover 1.1 and the second cover 1.2, in this embodiment, as image 3 As shown, the first cover 1.1 and the second cover 1.2 are mutually distributed. The second cover 1.2 is also provided with a fixed groove 1.2.3 that matches the bottle body. When in use, as long as the bottle mouth of the bottle to be pumped is connected to the fixed groove 1.2.3, the gas pumping tool The work of 4 extracts the gas from the vacuum pumping valve assembly, and ensures the vacuum sealing state through the function...

Embodiment 2

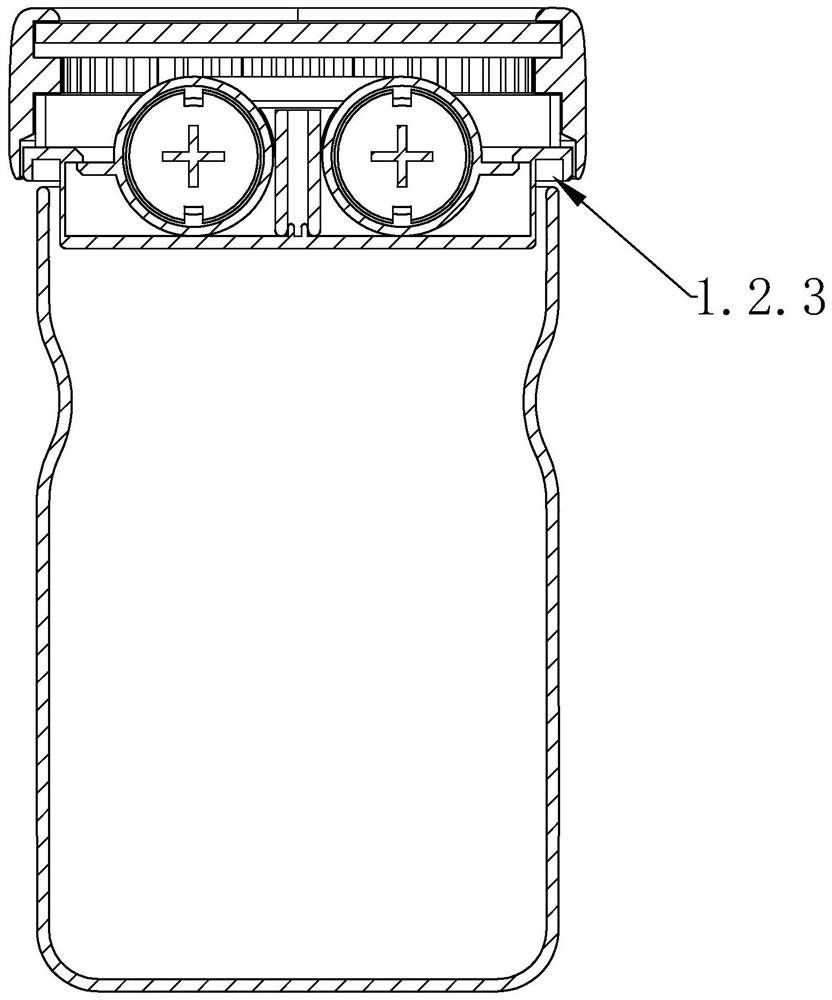

[0059] The basic structure is the same as that of Embodiment 1, the difference is that the cylinder body 4.1 can adopt double cylinders, of course, after adopting the double cylinders, the efficiency of vacuuming can be further improved, and the pumping is simpler.

[0060] The specific structural changes are as follows: Figure 4 As shown, after adopting the double bars, the same as the single cylinder also has a vacuum exhaust valve assembly, the difference is that the piston 4.2 and the piston rod 5.1 corresponding to the double cylinder in the exhaust tool 4 need to be increased. That is to say, the two cylinders 4.1 need two pistons 4.2 and two piston rods 5.1 correspondingly, and the two cylinders 4.1 are connected to each other, and the cylinders 4.1 are connected to the space to be pumped through the pumping valve core 2, Pistons 4.2 capable of reciprocating motion are respectively arranged in the two cylinders 4.1, and each piston 4.2 is respectively connected and fix...

Embodiment 3

[0062] Basic structure is identical with embodiment 2, and difference is: as Figure 8 to Figure 10 , a cam 5.6 is provided on the rotating shaft 5.3 at the bottom of the gear 5.2, and a push plate 5.7 is provided on the end of the piston rod 5.1 away from the piston 4.2. The length direction of the push plate 5.7 is perpendicular to the length direction of the piston rod 5.1, and the bottom of the push plate 5.7 A slide plate 5.8 is provided, and the length direction of the slide plate 5.8 is parallel to the length direction of the piston rod 5.1, that is to say the length direction of the slide plate 5.8 is perpendicular to the length direction of the push plate 5.7. The second cover body 1.2 is provided with a slide rail 1.2.2 matched with the slide plate 5.8, the slide plate 5.8 is provided with a first spring 5.9, and the other end of the first spring 5.9 is offset against the cylinder body 4.1 shell.

[0063]When in use, turn the first cover body 1.1, because the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com