Wet-grinding tailing-based mine filling cementing material and preparation method and application thereof

A technology for mine filling and cementitious materials, which is applied in the direction of cement production, etc., can solve the problems of low pollution and low cost, and achieve the effects of low pollution, low cost and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

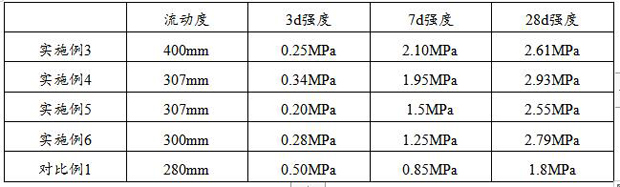

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the wet grinding tailings-based mine filling cementitious material described in the above technical solution, comprising the following steps:

[0038] a) After mixing the tailings, water-quenched slag and water, carry out wet grinding treatment to obtain slurry;

[0039] b) Add a powder sodium-based activator to the slurry obtained in step a), and perform dry mixing to obtain a cementitious material for mine filling based on wet grinding tailings.

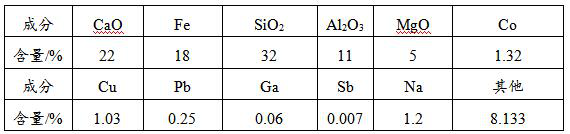

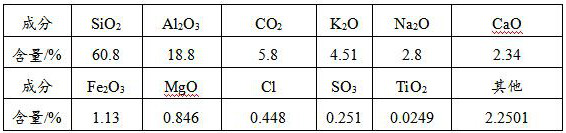

[0040] The invention first mixes the tailing sand, the water-quenched slag and water, and then performs wet grinding treatment to obtain the slurry. In the present invention, the tailings, water-quenched slag and water are the same as those in the above technical solution, and will not be repeated here.

[0041] In the present invention, zirconium silicate grinding balls are preferably used in the wet grinding process, and the ball-to-material ratio (mass ratio of ...

Embodiment 1

[0065] (1) After mixing 25 parts by weight of tailings and 25 parts by weight of water-quenched slag, add an equal amount (50 parts by weight) of water for wet grinding; the wet grinding process uses zirconium silicate grinding balls (particle size The mass ratio is 3mm: 2.5mm: 0.7mm=2:5:3), the ball-to-material ratio (mass ratio of the grinding ball to the solid in the waste slurry) is 2.5:1, the mill speed frequency is 45Hz, and the time is 50min; Obtain a slurry with a solid content of 50%;

[0066] The fineness D90 of the slurry is 8.8 μm, and the specific surface area is 950 m 2 / kg.

[0067] (2) Add 3 parts by weight of powder sodium-based activator to the slurry obtained in step (1), and dry-mix it in a mixer at a speed of 280±10r / min for 2 minutes to obtain a wet-grinding tailings-based mine filling gelling material.

Embodiment 2

[0069] (1) After mixing 25 parts by weight of tailings and 25 parts by weight of water-quenched slag, add 75 parts by weight of water for wet grinding treatment; the wet grinding treatment uses zirconium silicate grinding balls (the particle size and mass ratio are 3mm: 2.5mm: 0.7mm=2:5:3), the ball-to-material ratio (the mass ratio of the grinding ball to the solid in the waste slurry) is 2.5:1, the mill speed frequency is 45Hz, and the time is 50min; the solid content is 40 % of slurry;

[0070] The fineness D90 of the slurry is 9.4 μm, and the specific surface area is 916m 2 / kg.

[0071] (2) Add 3 parts by weight of powder sodium-based activator to the slurry obtained in step (1), and dry-mix it in a mixer at a speed of 280±10r / min for 2 minutes to obtain a wet-grinding tailings-based mine filling gelling material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com