Chopped strand mat reinforcing plate and preparation method thereof

A technology of chopped strand mat and reinforced board, which is applied in the direction of building components, building insulation materials, fire protection, etc., can solve the problems of imperfect wet board appearance, apparent lack of materials, trachoma, and high price, so as to save natural resources and Energy, low cost, and emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

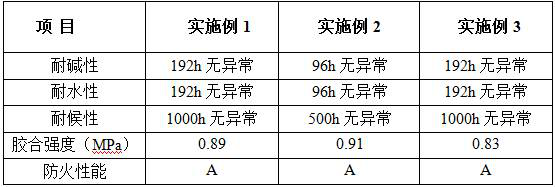

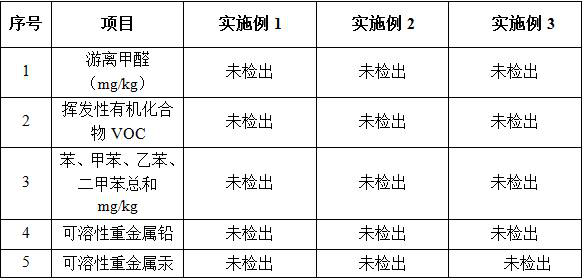

Examples

Embodiment 1

[0034] A kind of preparation method of chopped strand mat reinforcing board of the present invention comprises the following steps:

[0035] (1) Preparation of primer: Weigh each raw material by weight, 1000 parts of 42.5 grade rapid hardening low alkalinity sulfoaluminate cement, 46 parts of fly ash, 10 parts of silica fume, 1 part of glass fiber, 1 part of defoamer 2 parts of water reducing agent, 2 parts of retarder, 1 part of water retaining agent, 3 parts of rubber powder, 400 parts of water, after mixing evenly and stirring, add 650 parts of 8-40 mesh river sand, fully stir evenly, and get the base material ;

[0036] (2) Preparation of middle material: take each raw material by weight, 1000 parts of 42.5 grade quick-hardening low-alkalinity sulphoaluminate cement, 46 parts of fly ash, 10 parts of silica fume, 5 parts of glass fiber, 1 part of defoamer 2 parts of water reducing agent, 2 parts of retarder, 1 part of water retaining agent, 5 parts of rubber powder, 400 pa...

Embodiment 2

[0042] A method for preparing a chopped strand mat reinforcing plate, comprising the steps of:

[0043] (1) Prepare base material: take each raw material by weight, 1000 parts of 42.5 grade rapid hardening low alkalinity sulfoaluminate cement, 46 parts of fly ash, 10 parts of silica fume, 2 parts of glass fiber, 3 parts of defoamer 3 parts of water reducing agent, 2 parts of retarder, 1 part of water retaining agent, 3 parts of rubber powder, 400 parts of water, after mixing evenly and stirring, add 750 parts of 8-40 mesh river sand, fully stir evenly, and get the base material ;

[0044] (2) Preparation of middle material: take each raw material by weight, 1000 parts of 42.5 grade rapid hardening low alkalinity sulfoaluminate cement, 46 parts of fly ash, 10 parts of silica fume, 10 parts of glass fiber, 3 parts of defoamer 3 parts of water reducing agent, 2 parts of retarder, 1 part of water retaining agent, 5 parts of rubber powder, 400 parts of water, after mixing evenly, ...

Embodiment 3

[0050] A method for preparing a chopped strand mat reinforcing plate, comprising the steps of:

[0051] (1) Prepare base material: take each raw material by weight, 1000 parts of 42.5 grade rapid hardening low alkalinity sulfoaluminate cement, 46 parts of fly ash, 10 parts of silica fume, 1.5 parts of glass fiber, defoamer 2 2.5 parts of water-reducing agent, 2 parts of retarder, 1 part of water-retaining agent, 3 parts of rubber powder, 400 parts of water, after mixing evenly and stirring, add 700 parts of 20-mesh river sand, fully stir to obtain the base material;

[0052] (2) Preparation of middle material: take each raw material by weight, 1000 parts of 42.5 grade quick-hardening low-alkalinity sulphoaluminate cement, 46 parts of fly ash, 10 parts of silica fume, 8 parts of glass fiber, and 2 parts of defoamer 2.5 parts of water reducing agent, 2 parts of retarder, 1 part of water retaining agent, 5 parts of rubber powder, 400 parts of water, after mixing evenly, 2300 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com