Preparation method of flexible high-conductivity elastomer composite material

A technology of composite materials and elastomers, which is applied in the field of composite material preparation, can solve the problems of large impedance changes, uneven dispersion of inorganic conductive fillers, poor electrical stability, etc., and achieve the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

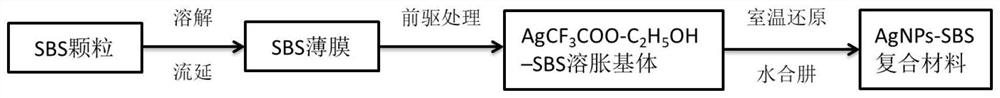

Method used

Image

Examples

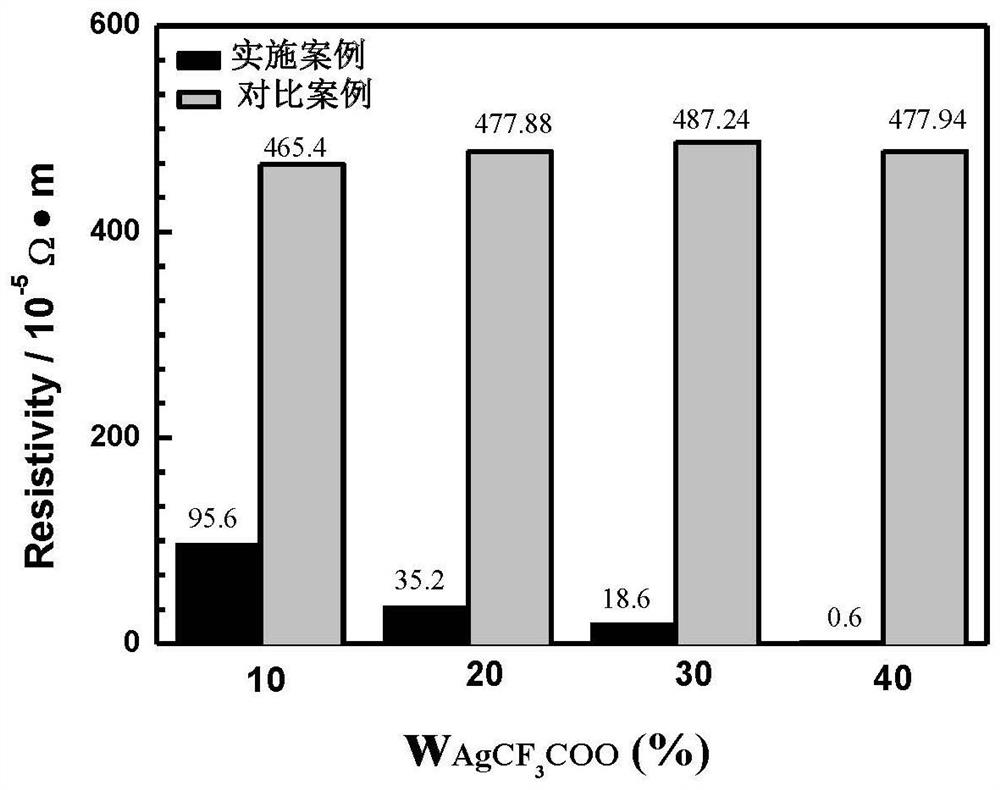

Embodiment 1

[0020] Take 5 g of granular styrene-butadiene-styrene (SBS) block copolymer and dissolve it in 60 g of tetrahydrofuran solution, sonicate for 30 minutes until the solution is clear and transparent. film, the solution was dried for 2 hours to form a sheet. Silver trifluoroacetate 5g (AgCF 3 COO) was dissolved in 45 g of ethanol solution, ultrasonicated for 20 minutes until the solution was light yellow, clear and transparent, which was recorded as AgCF 3 COO-C 2 h 5 OH (10 wt%) solution. The prepared SBS was cut into 1g strips by a punching machine, and then immersed in the prepared silver trifluoroacetate ethanol (10wt%) solution at room temperature to obtain the conductive precursor (AgCF) containing to be reduced. 3 COO) and swollen SBS, denoted as AgCF 3 COO-C 2 h 5 OH-SBS swelling matrix. AgCF 3 COO-C 2 h 5 The OH-SBS swelling matrix is immersed in an ethanol solution of hydrazine hydrate (hydrazine accounts for 50 wt%) at room temperature. Conductive silver ...

Embodiment 2

[0022] Take 5 g of granular styrene-butadiene-styrene (SBS) block copolymer and dissolve it in 60 g of tetrahydrofuran solution, sonicate for 30 minutes until the solution is clear and transparent. film, the solution was dried for 2 hours to form a sheet. Silver trifluoroacetate 10g (AgCF 3 COO) was dissolved in 40 g of ethanol solution, ultrasonicated for 20 minutes until the solution was light yellow and clear, which was recorded as AgCF 3 COO-C 2 h 5 OH (20 wt%) solution. The prepared SBS was cut into 1g strips by a punching machine, and then immersed in the prepared silver trifluoroacetate ethanol (20wt%) solution at room temperature to obtain the conductive precursor (AgCF) containing to be reduced. 3 COO) and swollen SBS, denoted as AgCF 3 COO-C 2 h 5 OH-SBS swelling matrix. AgCF 3 COO-C 2 h 5 The OH-SBS swelling matrix is immersed in an ethanol solution of hydrazine hydrate (hydrazine accounts for 50 wt%) at room temperature. The conductive nano-silver par...

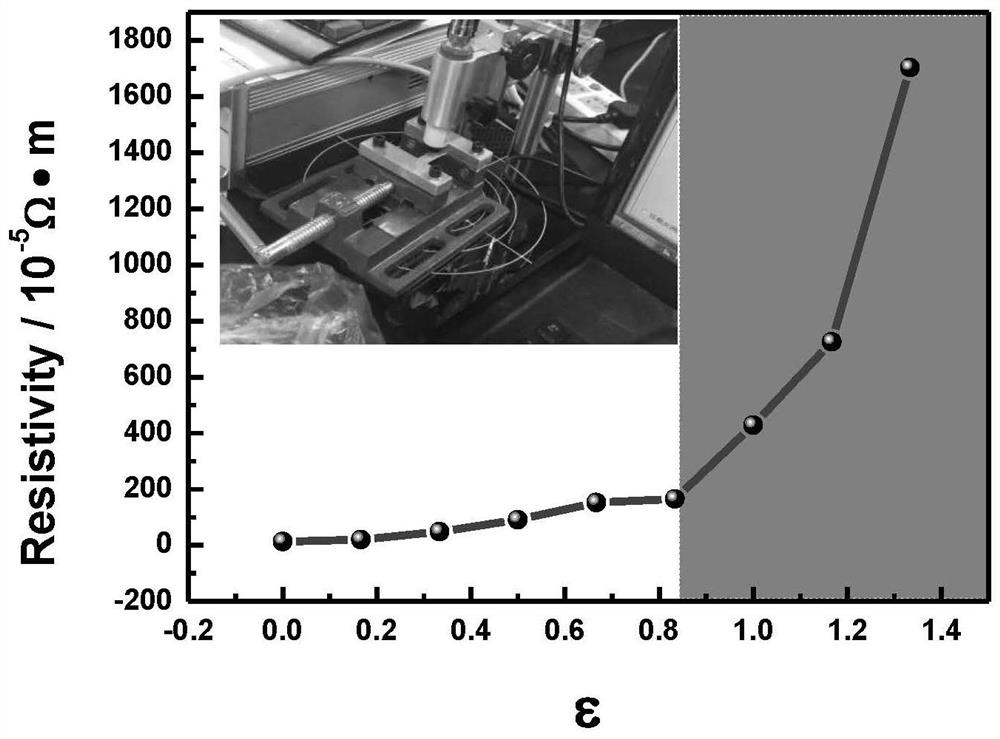

Embodiment 3

[0025] Take 5 g of granular styrene-butadiene-styrene (SBS) block copolymer and dissolve it in 60 g of tetrahydrofuran solution, sonicate for 30 minutes until the solution is clear and transparent. film, the solution was dried for 2 hours to form a sheet. Silver trifluoroacetate 15g (AgCF 3 COO) was dissolved in 35 g of ethanol solution, ultrasonicated for 20 minutes until the solution was light yellow, clear and transparent, which was recorded as AgCF 3 COO-C 2 h 5 OH (30 wt%) solution. The prepared SBS was cut into 1g strips by a punching machine, and then immersed in the prepared silver trifluoroacetate ethanol (30wt%) solution at room temperature to obtain the conductive precursor (AgCF) containing to be reduced. 3 COO) and swollen SBS, denoted as AgCF 3 COO-C 2 h 5 OH-SBS swelling matrix. AgCF 3 COO-C 2 h 5 The OH-SBS swelling matrix is immersed in an ethanol solution of hydrazine hydrate (hydrazine accounts for 50 wt%) at room temperature. While the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com