Fennel vinegar and brewing process thereof

A technology of fennel and acetic acid fermentation, which is applied in the field of condiments, can solve the problems of not really realizing the edible value and medical value of fennel vinegar, not being able to treat, and not having obvious effects, so as to help blood circulation, eliminate fishy smell, increase effect of appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

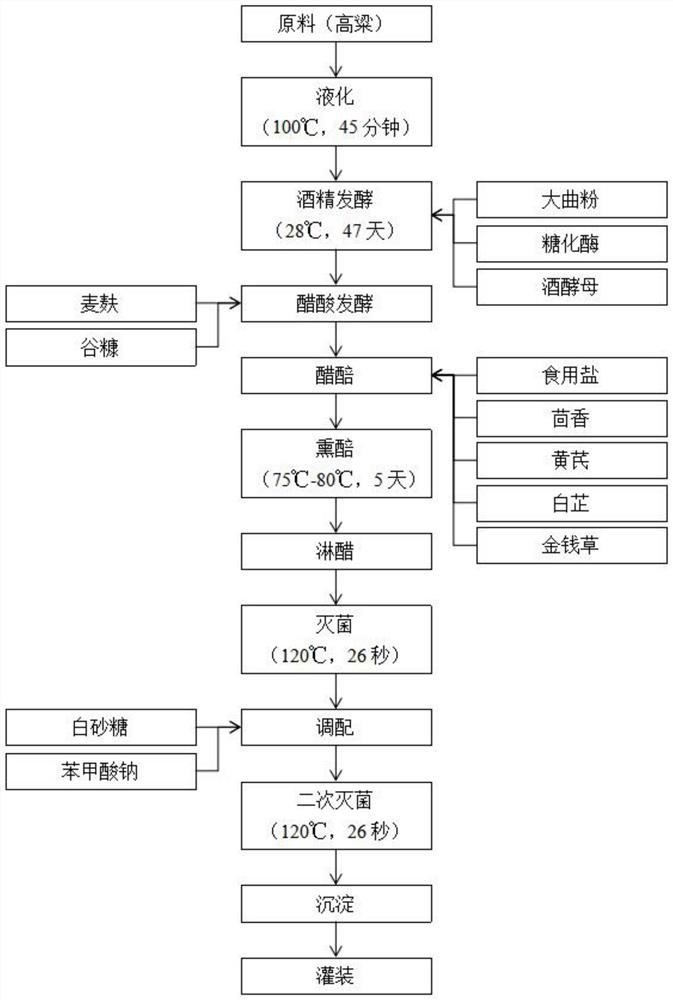

[0033] see figure 1 , the present invention provides a technical solution, a kind of fennel vinegar, by weight, comprising 20-30 parts of sorghum flour, 4-6 parts of Daqu powder, 0.8-1.2 parts of amylase, 0.004-0.006 parts of glucoamylase, brewer's yeast 0.002-0.004 parts, 20-30 parts of bran, 40-50 parts of rice bran, 1-3 parts of edible salt, 0.8-1.2 parts of fennel, 0.1-5 parts of Astragalus, 0.1-2 parts of Angelica dahurica, 0.1-2 parts of Desmodium , 1-20 parts of white granulated sugar and 0.4-0.8 parts of sodium benzoate.

[0034] Wherein, in the present embodiment, the brewing process of described fennel vinegar comprises the following steps:

[0035] S1: Raw material preparation: by weight, 20-30 parts of sorghum flour, 4-6 parts of Daqu powder, 0.8-1.2 parts of amylase, 0.004-0.006 parts of glucoamylase, 0.002-0.004 parts of wine yeast, 20-30 parts of bran 40-50 parts of rice bran, 1-3 parts of edible salt, 0.8-1.2 parts of fennel, 0.1-5 parts of astragalus, 0.1-2 ...

Embodiment 2

[0051] see figure 1 , the present invention provides a technical solution, a kind of fennel vinegar, by weight, comprising 20-30 parts of sorghum flour, 4-6 parts of Daqu powder, 0.8-1.2 parts of amylase, 0.004-0.006 parts of glucoamylase, brewer's yeast 0.002-0.004 parts, 20-30 parts of bran, 40-50 parts of rice bran, 1-3 parts of edible salt, 0.8-1.2 parts of fennel, 0.1-5 parts of Astragalus, 0.1-2 parts of Angelica dahurica, 0.1-2 parts of Desmodium , 1-20 parts of white granulated sugar and 0.4-0.8 parts of sodium benzoate.

[0052] Wherein, in the present embodiment, the brewing process of described fennel vinegar comprises the following steps:

[0053] S1: Raw material preparation: by weight, 20-30 parts of sorghum flour, 4-6 parts of Daqu powder, 0.8-1.2 parts of amylase, 0.004-0.006 parts of glucoamylase, 0.002-0.004 parts of wine yeast, 20-30 parts of bran 40-50 parts of rice bran, 1-3 parts of edible salt, 0.8-1.2 parts of fennel, 0.1-5 parts of astragalus, 0.1-2 ...

Embodiment 3

[0069] see figure 1 , the present invention provides a technical solution, a kind of fennel vinegar, by weight, comprising 20-30 parts of sorghum flour, 4-6 parts of Daqu powder, 0.8-1.2 parts of amylase, 0.004-0.006 parts of glucoamylase, brewer's yeast 0.002-0.004 parts, 20-30 parts of bran, 40-50 parts of rice bran, 1-3 parts of edible salt, 0.8-1.2 parts of fennel, 0.1-5 parts of Astragalus, 0.1-2 parts of Angelica dahurica, 0.1-2 parts of Desmodium , 1-20 parts of white granulated sugar and 0.4-0.8 parts of sodium benzoate.

[0070] Wherein, in the present embodiment, the brewing process of described fennel vinegar comprises the following steps:

[0071] S1: Raw material preparation: by weight, 20-30 parts of sorghum flour, 4-6 parts of Daqu powder, 0.8-1.2 parts of amylase, 0.004-0.006 parts of glucoamylase, 0.002-0.004 parts of wine yeast, 20-30 parts of bran 40-50 parts of rice bran, 1-3 parts of edible salt, 0.8-1.2 parts of fennel, 0.1-5 parts of astragalus, 0.1-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com