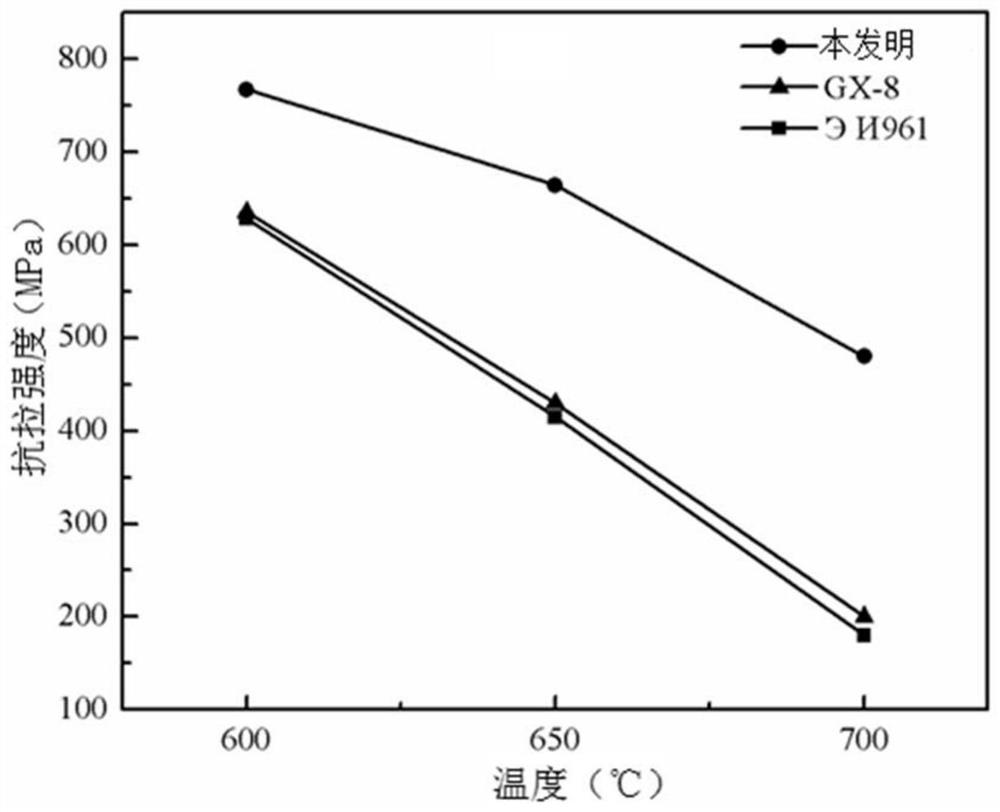

A kind of high-temperature high-strength low-carbon martensitic hot-strength steel and its preparation method

A technology of low-carbon martensite and heat-strength steel, which is applied in the field of aero-engines, can solve problems such as working temperature limit, difficulty in meeting the strength and safety requirements of load-bearing components, and insufficient high-temperature strength, so as to achieve high temperature resistance and improve application stability The effect of avoiding the precipitation of delta ferrite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a method for preparing high-temperature, high-strength, low-carbon martensitic heat-strength steel according to any of the above-mentioned embodiments, comprising the following steps:

[0063] Smelting steps: Prepare raw materials according to the following mass percentages:

[0064] C: 0.10~0.25wt%, Cr: 10.0~13.0wt%, Ni: 2.0~3.2wt%, Mo: 1.50~2.50wt%, Si≤0.60wt%, Mn≤0.60wt%, W: 0.4~0.8wt% %, V: 0.1-0.5wt%, Co: 0.3-0.6wt%, Al: 0.3-1.0wt%, Nb: 0.01-0.2wt%, the rest is Fe, and then the raw materials are smelted to obtain a smelted billet.

[0065] The process of raw material smelting is well known to those skilled in the art, and the present invention is not particularly limited. For example, the method of vacuum induction melting + electroslag remelting (ESR) can be used, and electric arc furnace (EAF) + refining (LF) can also be used. + Vacuum degassing (VD) + Electroslag remelting (ESR) and other smelting methods that can guarantee t...

Embodiment 1

[0086]

[0087] Prepare raw materials by the following mass percentages:

[0088] C: 0.14wt%, Cr: 10.3wt%, Ni: 2.05wt%, Mo: 1.55wt%, Si: 0.35wt%, Mn: 0.31wt%, W: 0.42wt%, V: 0.16wt%, Nb: 0.08wt%, Co: 0.3wt%, Al: 0.28wt%, and the rest is Fe, and the raw materials are smelted to obtain a smelted billet.

[0089]

[0090] For the forging of the smelted slab, the initial forging temperature is 1100°C, and the final forging temperature is 880°C to obtain steel ingots.

[0091]

[0092] Carry out normalizing treatment to the steel ingot, the normalizing treatment temperature is 1100 ℃, the holding time is 3h, and then air-cooled to room temperature.

[0093]

[0094] Heat the heat-treated ingot to 1150°C in a high-temperature furnace for 2 hours, then water-cool it to room temperature, then heat it to 580°C and temper it for 2 hours, then cool it to room temperature, and heat the tempered steel ingot at 480°C for 6 hours. Then cool to room temperature.

Embodiment 2

[0096]

[0097] Prepare raw materials by the following mass percentages:

[0098] C: 0.18wt%, Cr: 12.8wt%, Ni: 2.53wt%, Mo: 2.44wt%, Si: 0.4wt%, Mn: 0.51wt%, W: 0.38wt%, V: 0.23wt%, Nb: 0.12wt%, Co: 0.33wt%, Al: 0.31wt%, and the rest is Fe. The raw materials are smelted to obtain a smelted billet.

[0099]

[0100] For smelting slab forging, the initial forging temperature is 1100°C and the final forging temperature is 860°C to obtain steel ingots.

[0101]

[0102] The steel ingot is annealed at 900°C, held for 8 hours, then cooled to 520°C with the furnace, and then air-cooled to room temperature.

[0103]

[0104] Heat the heat-treated ingot to 1200°C in a high-temperature furnace for 1 hour, then water-cool it to room temperature, then heat it to 600°C and temper it for 2 hours, then cool it to room temperature, and then heat the tempered steel ingot at 500°C for 4 hours. Then cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com