Gas injection pipeline movable sealing system and method for underground coal gasification

A technology of underground gasification and mobile sealing, which is applied in the directions of sealing/sealing, earth-moving drilling, and fluid production, etc., can solve problems such as leakage of combustible gas, and achieve the effect of reducing waste, good sealing performance, and convenient retreat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

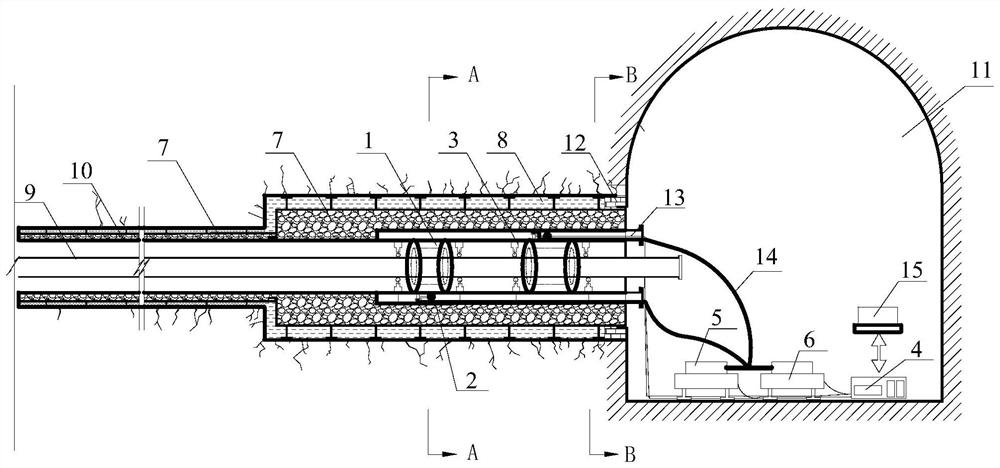

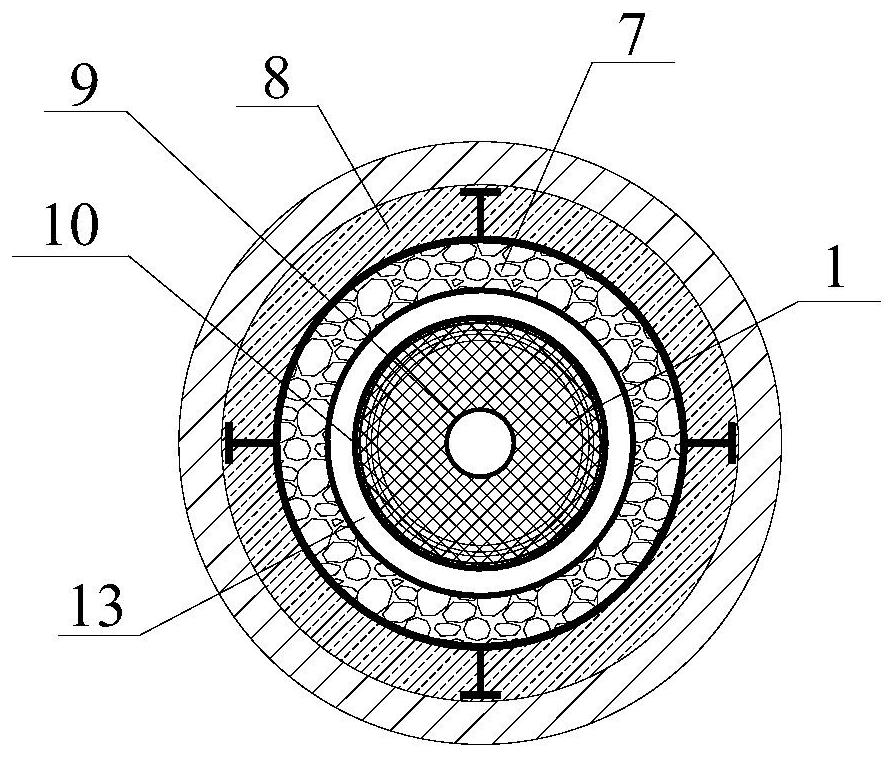

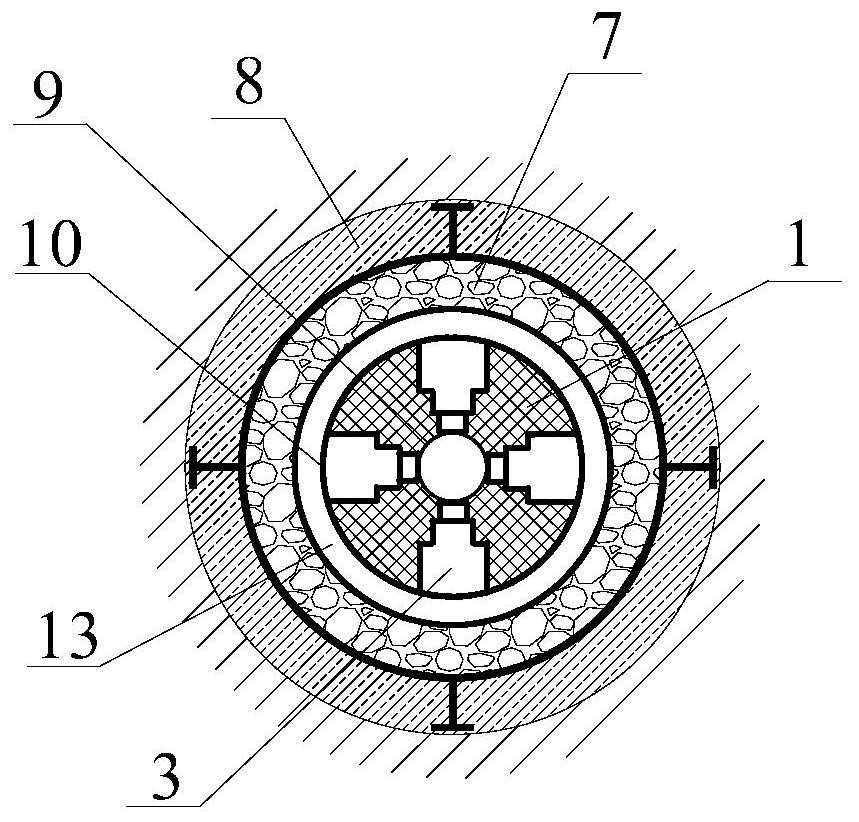

[0030] to combine Figure 1 to Figure 4 As shown, the specific implementation of a gas injection pipeline moving sealing system and method for underground coal gasification provided by the present invention will be described.

[0031] A moving sealing system for the gas injection pipeline for underground coal gasification, which solves the problem that the high-temperature and high-pressure combustible gas in the gasifier runs along the gap between the gas injection pipe and the protection pipe caused by the retreat of the gas injection pipeline during the underground coal gasification process. The problem of leaking through gaps between them, its structure specifically includes an annular air bag 1, a pressure sensor 2, a hydraulic support component 3, a controller 4, an air compressor 5, a vacuum pump 6, a temperature-resistant cement layer 7 and a high-strength temperature-resistant layer 8, the system Reasonable design, high operability, better sealing and high temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com