Reaming and sucking type spiral conveyor capable of preventing cutter head from caking

A screw conveyor and hinge suction technology, applied in the field of hinge suction screw conveyor, can solve the problems of mud cake on the cutter head, affecting the construction progress, delay of the construction period, etc., so as to prevent the mud cake on the cutter head and increase the discharge speed , The effect of preventing drying and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

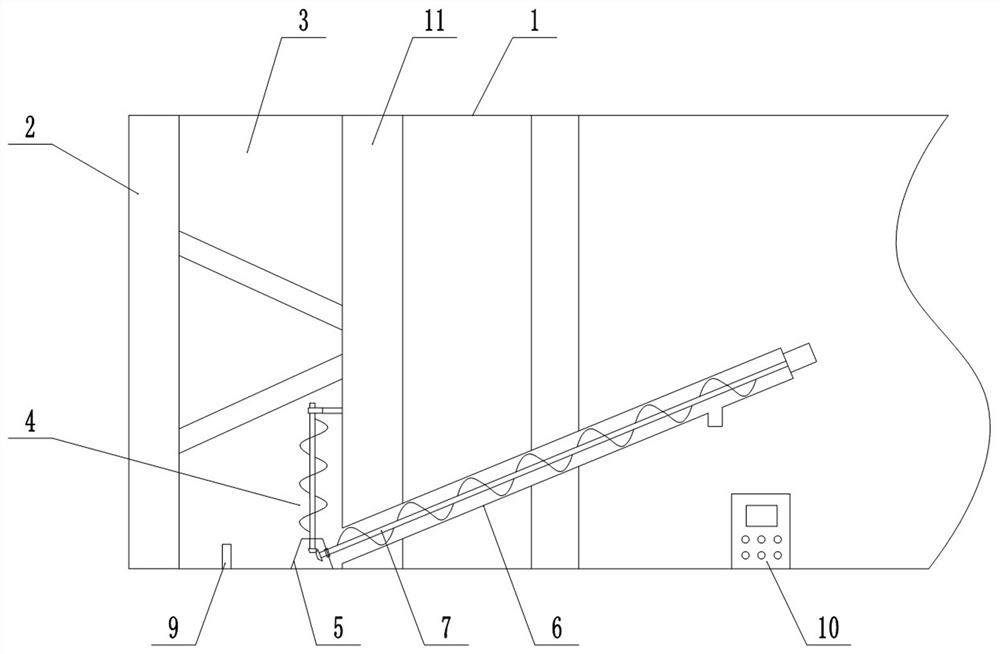

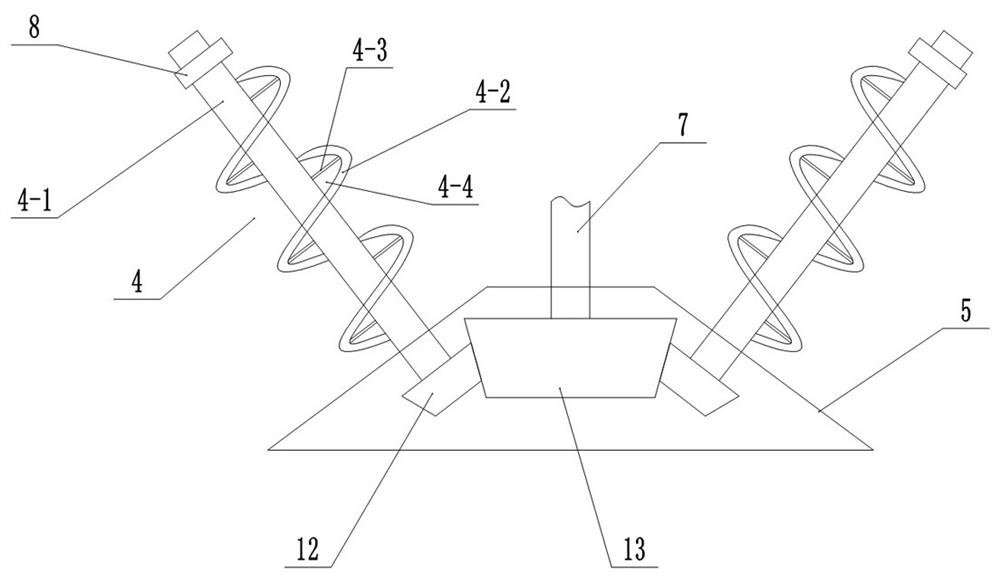

[0019] Such as Figure 1-Figure 2 As shown, the present invention provides a hinged suction screw conveyor 6 that prevents the cutter head 2 from forming cakes, including a pair of hinged suction mechanisms 4 arranged in the soil bin 3 of the shield machine 1, and one end of the hinged suction mechanism 4 The support bearing 8 is fixedly installed on the inner wall 11 of the soil bin 3, and the other end of the hinge suction mechanism 4 is connected with the rotating shaft 7 of the screw conveyor 6 used to transport the muck in the soil bin 3 through a transmission mechanism. 6 is driven by a drive motor.

[0020] The hinge suction mechanism 4 is used to stir the slag, bentonite, foam and other substances inside the soil bin 3, so that the slag sample is evenly moistened and stirred to prevent the slag from drying and solidifying at high temperature. The hinge suction mechanism 4 includes a rotating rod 4- 1. The rotating rod 4-1 is provided with a spiral stirring belt 4-2 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com