Bearing equipment and arm tooth fork thereof

A tooth fork and arm technology, which is applied in the field of liquid crystal panel process automation, can solve problems such as abnormal single-point alignment, large internal stress on the glass substrate, damage, etc., to improve product yield and production line capacity, and reduce single-point alignment abnormalities ratio, to improve the effect of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

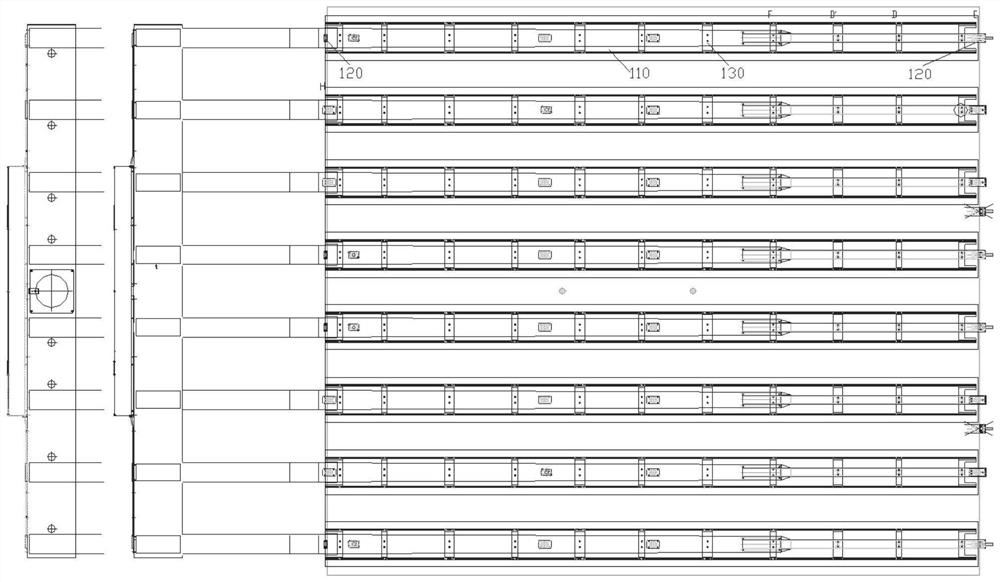

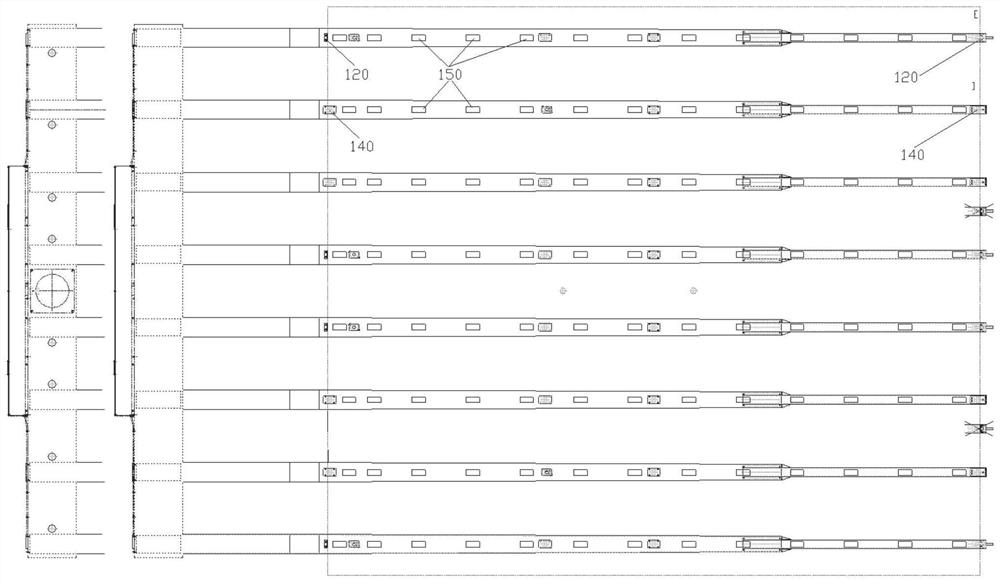

[0020] In the following, the carrying device and its arm tooth fork provided by the present invention will be explained and described in detail in conjunction with the accompanying drawings.

[0021] figure 1 Schematic diagram of the structure of the arm dental fork provided as an example of the present invention. figure 2 Schematic diagram of the structure of the arm dental fork provided for another example of the present invention. Such as figure 1 with figure 2 As shown, the arm dental fork provided in Embodiment 1 includes a plurality of tines and a cap frame bar 110 fixed on at least one of the multiple tines, the extending direction of the cap frame bar 110 and the extending direction of the prongs where it is located parallel. The shape of the hat frame bar 110 can increase the contact area with the glass substrate, so as to reduce the internal stress of the glass substrate. Wherein, at least the top of the hat frame bar 110 is made of elastic material. The elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com