Heat dissipation structure of plasma display screen

A technology of plasma display screen and heat dissipation structure, which is applied in the construction of electrical equipment components, modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., which can solve display blurring, brightness reduction, and affect the service life of plasma display screens, etc. problem, achieve the effect of increasing the service life and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

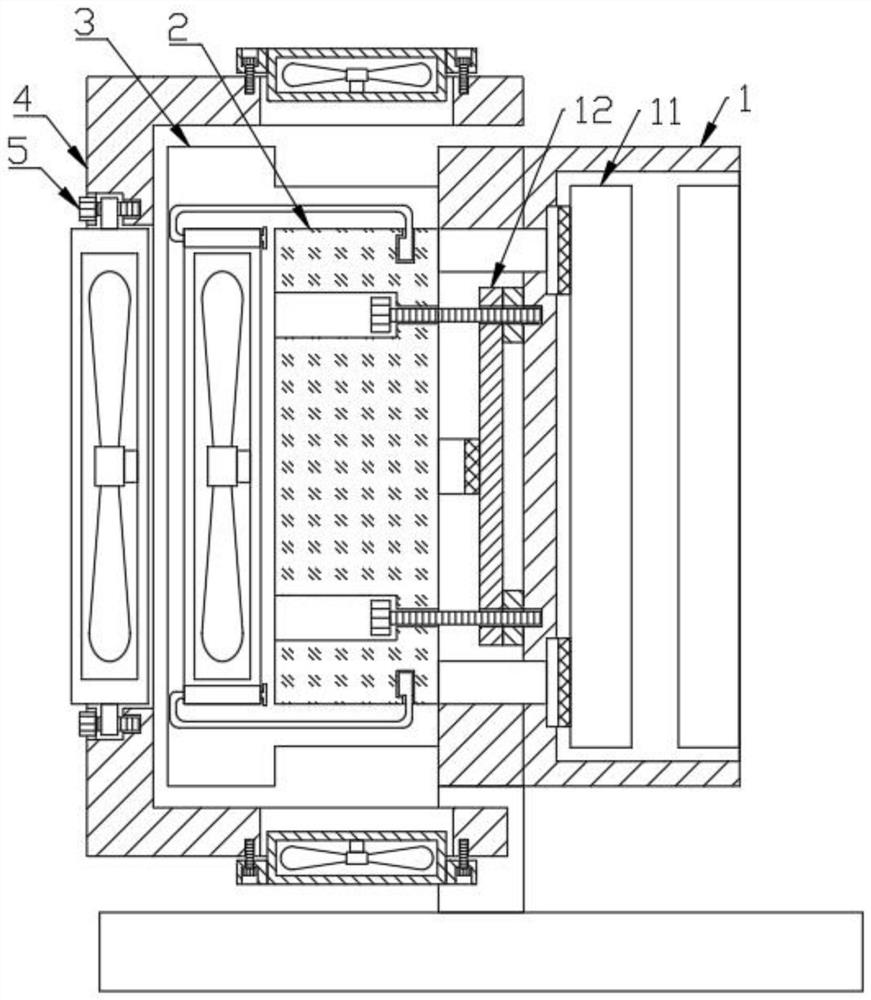

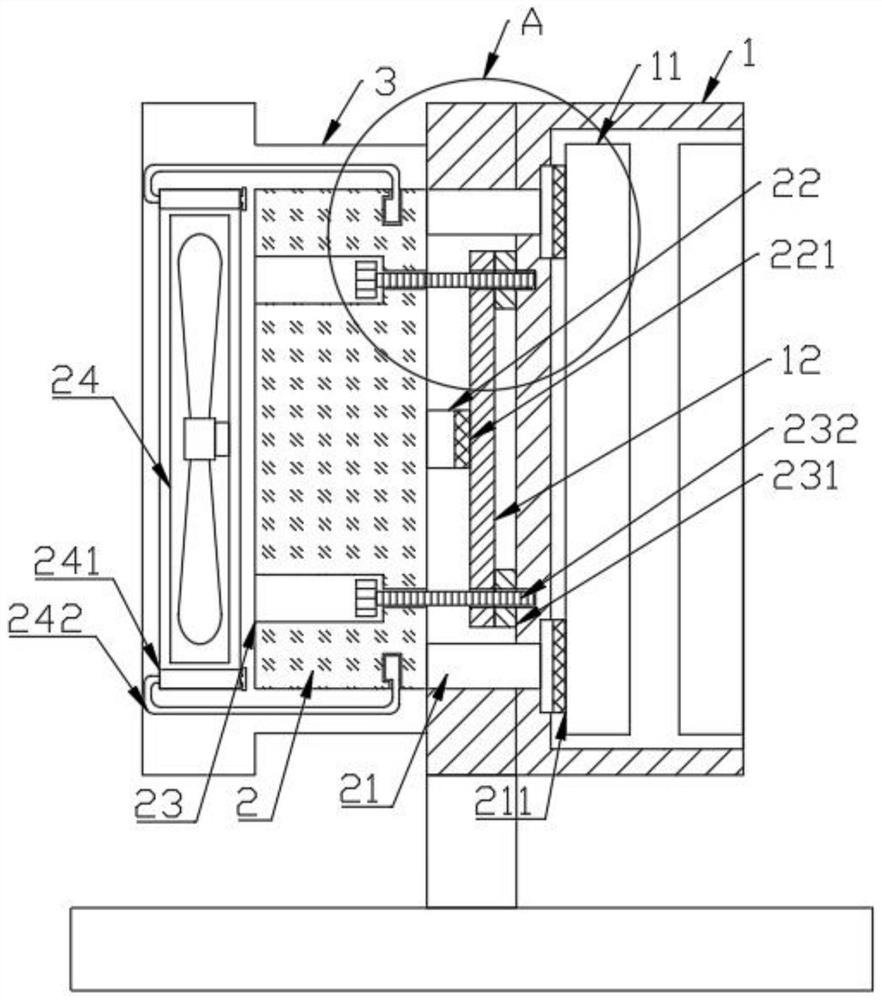

[0032] Embodiment 1, with reference to attached Figure 1-5 , a heat dissipation structure of a plasma display screen provided by the present invention, comprising a display screen 1, a heat sink 2, a rear cover 3, a heat dissipation device 4 and a fixing device 5;

[0033] Further, a cooling fin 2 is fixedly installed at the left end of the display screen 1, and the display screen 1 includes a vacuum glass 11 and a main board 12. Specifically, the right end of the display screen 1 is connected to the vacuum glass 11, and the left end of the vacuum glass 11 is provided with a main board 12. 11 is a new type of glass deep-processing product, which is developed based on the principle of a vacuum flask. The main board 12 is also called a main board, a system board or a motherboard. It is installed in the case and is one of the most basic and important components of a microcomputer. Inject inert gas or mercury vapor into the vacuum glass 11, and then electrically connect the main ...

Embodiment 2

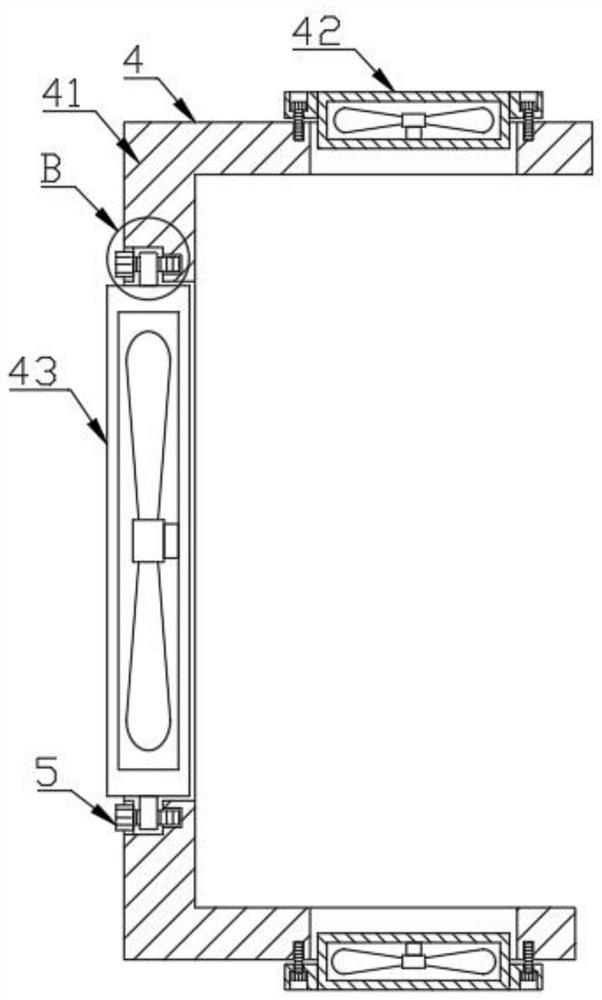

[0038] Embodiment 2, with reference to attached Figure 1-5 , a heat dissipation structure of a plasma display screen provided by the present invention, comprising a fixing device 5;

[0039] Further, the fixing device 5 is welded on the upper and lower ends of the second cooling fan 43, and the fixing device 5 also includes a bump 52, a rubber block 521 and a rubber groove 522. Specifically, the bump 52 is welded on the upper and lower ends of the second cooling fan 43 , the right end of the bump 52 is bonded with a rubber block 521, and the upper and lower ends of the left side of the fixed frame 41 are provided with a rubber groove 522. Since the bump 52 is welded to the upper and lower ends of the second heat dissipation fan 43, the right end of the bump 52 is bonded with a rubber block 521. The upper and lower ends of the left side of the fixed frame 41 are provided with rubber grooves 522, which are inserted into the rubber grooves 522 through the rubber blocks 521 to pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com