Metal material machining waste treatment device

A technology for waste material treatment and metal materials, applied in metal processing equipment, grinding drive devices, grinding/polishing safety devices, etc., can solve the problems of unstable use, easy to dump, high risk factor, etc., and achieve fast and convenient use The effect of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

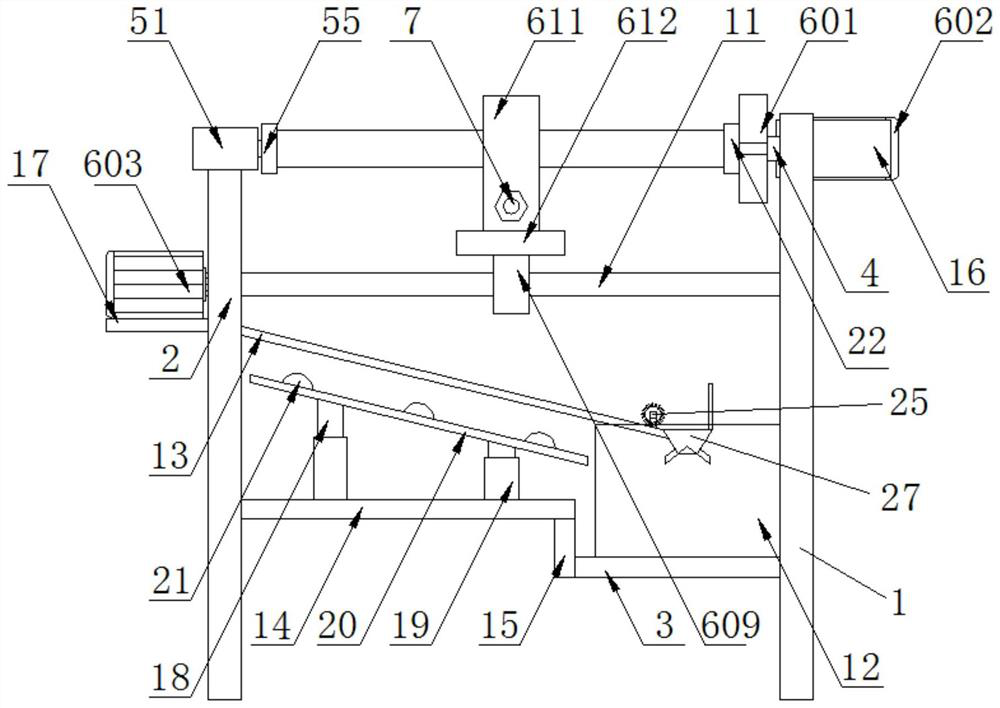

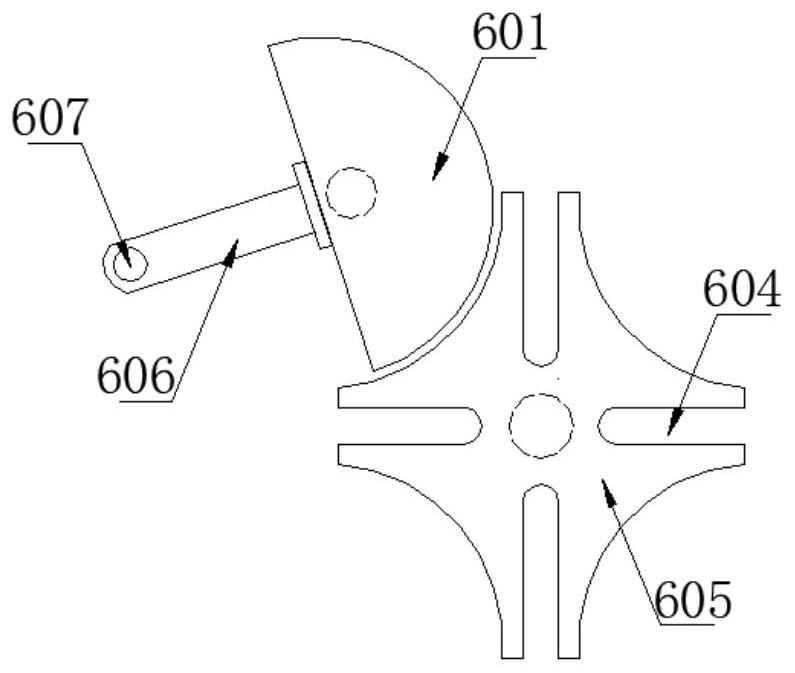

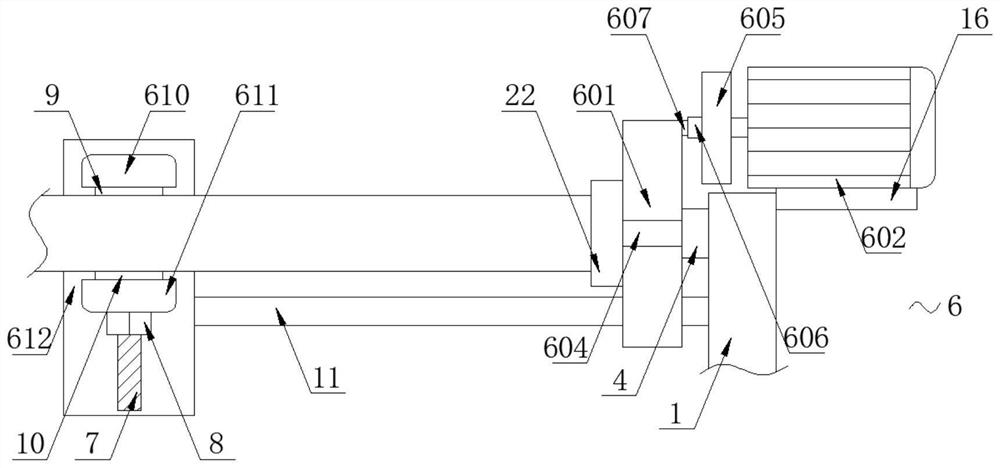

[0035] Including the first support plate 1 and the second support plate 2, one side of the first support plate 1 is fixedly connected with the first fixed plate 3, one side of the second support plate 2 is fixedly connected with the second fixed plate 14, the second fixed plate 1 The bottom of the plate 14 and the top of the first fixed plate 3 are fixedly connected by a vertical plate 15, one side of the first support plate 1 is rotatably connected with a support shaft 4, and the top of the second support plate 2 is provided with a clamping mechanism 5, The first support plate 1 and the second support plate 2 are provided with a polishing mechanism 6; the polishing mechanism 6 includes a rotating disc 601, a rotating motor 602 and a polishing motor 603, the polishing motor 603 is a three-phase asynchronous motor, and the outer surface of the rotating disc 601 is provided There is a card slot 604, the output end of the rotating motor 602 is fixedly connected with a rotating pla...

Embodiment 2

[0037] Including the first support plate 1 and the second support plate 2, one side of the first support plate 1 is fixedly connected with the first fixed plate 3, one side of the second support plate 2 is fixedly connected with the second fixed plate 14, the second fixed plate 1 The bottom of the plate 14 and the top of the first fixed plate 3 are fixedly connected by a vertical plate 15, one side of the first support plate 1 is rotatably connected with a support shaft 4, and the top of the second support plate 2 is provided with a clamping mechanism 5, The first support plate 1 and the second support plate 2 are provided with a polishing mechanism 6; the polishing mechanism 6 includes a rotating disc 601, a rotating motor 602 and a polishing motor 603, the polishing motor 603 is a three-phase asynchronous motor, and the outer surface of the rotating disc 601 is provided There is a card slot 604, the output end of the rotating motor 602 is fixedly connected with a rotating pla...

Embodiment 3

[0042] Including the first support plate 1 and the second support plate 2, one side of the first support plate 1 is fixedly connected with the first fixed plate 3, one side of the second support plate 2 is fixedly connected with the second fixed plate 14, the second fixed plate 1 The bottom of the plate 14 and the top of the first fixed plate 3 are fixedly connected by a vertical plate 15, one side of the first support plate 1 is rotatably connected with a support shaft 4, and the top of the second support plate 2 is provided with a clamping mechanism 5, The first support plate 1 and the second support plate 2 are provided with a polishing mechanism 6; the polishing mechanism 6 includes a rotating disc 601, a rotating motor 602 and a polishing motor 603, the polishing motor 603 is a three-phase asynchronous motor, and the outer surface of the rotating disc 601 is provided There is a card slot 604, the output end of the rotating motor 602 is fixedly connected with a rotating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com