Preparation method of tannin grafted draping double bonds

A technique of pendant and tannin, which is applied in the field of preparation of tannin grafted pendant double bonds, can solve the problems of difficult separation, large molecular weight, complex products, etc., and achieve simple and easy preparation methods, mild implementation conditions and pure products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

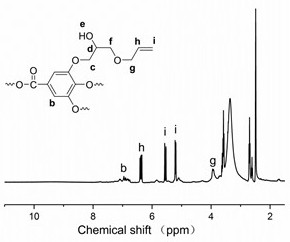

Image

Examples

Embodiment 1

[0012] Embodiment 1: Synthesis of tannin grafted allyl glycidyl ether with a molar ratio of 1:15:

[0013] Weigh a certain amount of 2 g of tannin, place it in a vacuum drying oven, and dry it at 50° C. for 6 hours. Add to the flask, add 2.8g allyl glycidyl ether and 0.14g triphenylphosphine respectively, and react at 95°C for 4h. Naturally cool to room temperature, add 1.5 times the total amount of tannin and allyl glycidyl ether in ethanol to dissolve for 12 hours, then settle for 20 minutes under magnetic stirring with petroleum ether, use a vacuum pump to dry the circulating water type, and let it dry naturally for 12 hours. Dry in a vacuum oven at 35°C for 24 hours.

Embodiment 2

[0014] Embodiment 2: Synthesis of tannin grafted allyl glycidyl ether with a molar ratio of 1:25:

[0015] Weigh a certain amount of 2 g of tannin, place it in a vacuum drying oven, and dry it at 50° C. for 6 hours. Add to the flask, add 4.65g allyl glycidyl ether and 0.14g triphenylphosphine respectively, and react at 95°C for 4h. Naturally cool to room temperature, add 1.5 times the total amount of tannin and allyl glycidyl ether in ethanol to dissolve for 12 hours, then settle for 20 minutes under magnetic stirring with petroleum ether, use a vacuum pump to dry the circulating water type, and let it dry naturally for 12 hours. Dry in a vacuum oven at 35°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com