Casein-based dual-network antibacterial composite hydrogel material and preparation method thereof

A composite hydrogel and casein technology is applied in the field of polymer biomaterial preparation, which can solve the problems of easy mildew and spoilage, poor antibacterial performance, etc., and achieve the effects of excellent hygienic performance, stable performance and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

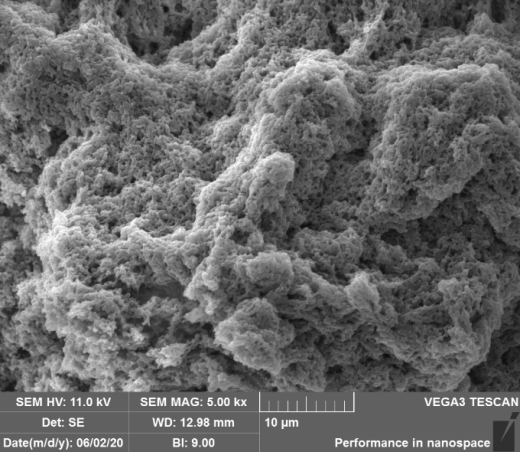

Image

Examples

Embodiment 1

[0029] The mass of the prepared casein-based double network composite hydrogel is 100 parts, in parts by mass.

[0030] Step 1: Take a certain amount of deionized water, use triethanolamine to adjust pH=10; add 1.25 parts by mass of casein powder to 98.65 parts by mass of triethanolamine solution, mix and add to a three-necked flask and continue stirring with a stirrer, and heat in a water bath to The temperature is 45°C, the magnetic stirring speed is controlled at 500 r / min, and the stirring is continued for 1 h until it dissolves to obtain a casein dispersion;

[0031] Step 2: Take 0.10 parts by mass of zinc oxide nanoparticles and add them into deionized water, and magnetically stir at room temperature until they are uniformly dispersed to obtain a zinc oxide dispersion. Slowly add it to the casein dispersion while stirring, and ultrasonically react at 45°C for 1 h, so that the nano-zinc oxide is evenly dispersed between the casein molecules, and a mixed dispersion is obta...

Embodiment 2

[0034] The mass of the prepared casein-based double network composite hydrogel is 100 parts, in parts by mass.

[0035] Step 1: Take a certain amount of deionized water, use triethanolamine to adjust pH=10; add 1.35 parts by mass of casein powder to 98.40 parts by mass of triethanolamine solution, mix and add to a three-necked flask and continue stirring with a stirrer, and heat in a water bath to The temperature is 45°C, the magnetic stirring speed is controlled at 500 r / min, and the stirring is continued for 1 h until it dissolves to obtain a casein dispersion;

[0036] Step 2: Take 0.25 parts by mass of zinc oxide nanoparticles and add them into deionized water, and magnetically stir at room temperature until they are uniformly dispersed to obtain a zinc oxide dispersion. Slowly add it to the casein dispersion while stirring, and ultrasonically react at 45°C for 1 h, so that the nano-zinc oxide is evenly dispersed between the casein molecules, and a mixed dispersion is obtain...

Embodiment 3

[0039] The mass of the prepared casein-based double network composite hydrogel is 100 parts, in parts by mass.

[0040] Step 1: Take a certain amount of deionized water, use triethanolamine to adjust pH=10; add 1.45 parts by mass of casein powder to 98.15 parts by mass of triethanolamine solution, mix and add to a three-necked flask and continue stirring with a stirrer, and heat in a water bath to The temperature is 45°C, the magnetic stirring speed is controlled at 500 r / min, and the stirring is continued for 1 h until it dissolves to obtain a casein dispersion;

[0041] Step 2: Take 0.40 parts by mass of zinc oxide nanoparticles and add them into deionized water, and magnetically stir at room temperature until they are uniformly dispersed to obtain a zinc oxide dispersion. Slowly add it to the casein dispersion while stirring, and ultrasonically react at 45°C for 1 h, so that the nano-zinc oxide is evenly dispersed between the casein molecules, and a mixed dispersion is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com