Low-temperature radiating electrical bar heating system

A heating system and low-temperature radiation technology, which is applied in the field of heating systems, can solve the problems of poor heat preservation effect, low safety factor, and electricity consumption of electric heating equipment, and achieve the effects of fast heating speed, saving electricity, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

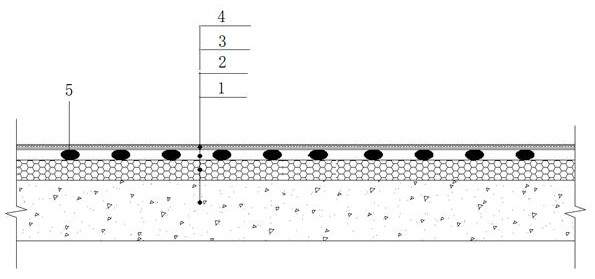

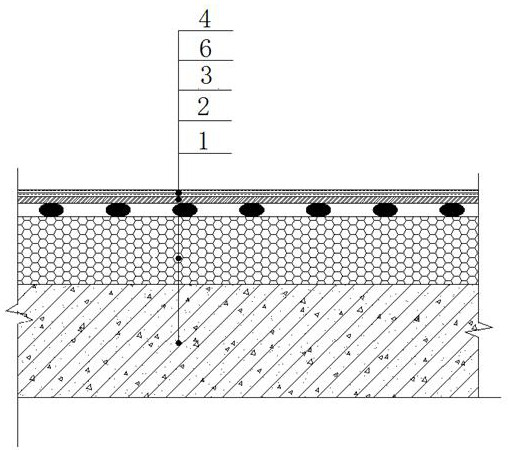

[0039] combine figure 1 , a low-temperature radiant electric heating rod heating system in this embodiment, comprising: a thermal insulation layer 2, the thermal insulation layer 2 is a structural layer used to block heat transfer and reduce ineffective heat loss, and the thermal insulation layer 2 is installed on the structure Above the plate layer 1; an electric heating layer 3, the electric heating layer 3 is formed by parallel connection of several electric heating rods 5, and the electric heating rod 5 is composed of graphite outsourcing resin insulation skin, and the electric heating layer 3 is arranged on the heat insulating On the layer 2; the finish layer 4, the finish layer 4 is arranged on the electric heating layer 3, and the thermal resistance of the finish layer 4 is less than 0.05 (m 2 · k) / w; the cross-section of the electric heating rod 5 is elliptical, its major axis is not less than 8 mm, and its minor axis is not less than 5 mm.

[0040] When the system is...

Embodiment 2

[0051] Compared with Example 1, the low-temperature heat radiation electric heating rod heating system of this embodiment furthermore, the number of electric heating rods 5 required for heating the room satisfies the following relationship:

[0052] N=(1+k)P / Pm

[0053] Among them, N-the number of electric heating rods required (m); P-room heat load value (w); Pm-effective power of electric heating rods per meter for heating the room (w); k-additional operating coefficient.

[0054] As a further improvement of this scheme, the calculation relation of room heat load value is as follows:

[0055] P=α*Qj+qh*M

[0056] Qj=ß*f*k 1 *(tn-tw)

[0057] Among them, α-the correction coefficient of intermittent heating; Qj-the basic heat load of the room (w); qh-the average heat transfer between rooms per unit area of the room, take 7w / m 2 ; M- room use area (m 2 ); ß-envelope temperature correction coefficient; f-envelope area (m 2 ); k 1 - Heat transfer coefficient of envelope ...

Embodiment 3

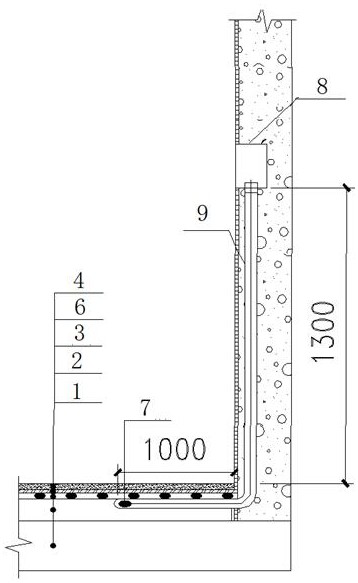

[0061] Compared with Embodiment 2, a low-temperature heat radiation electric heating rod heating system of this embodiment further combines image 3 , also includes a temperature control device, the temperature control device is attached to the electric heating layer 3, the temperature control device is used to control the temperature of the electric heating layer 3, the temperature control device includes a temperature probe 7 and a temperature controller 8, The temperature-sensing probe 7 is attached to the electric heating layer 3 , the temperature controller 8 is connected to a power supply, and the temperature-sensing probe 7 and the temperature controller 8 are connected through a signal line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com